Heat treatment method for high-strength large-size aluminum alloy thick-wall ring part with controllable elongation

A heat treatment method and technology of aluminum alloy, applied in the field of heat treatment of aluminum alloy thick-walled rings, can solve the problems of ring wall thickness, low alloy strength, large size, etc., and achieve the effect of improving strength, toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

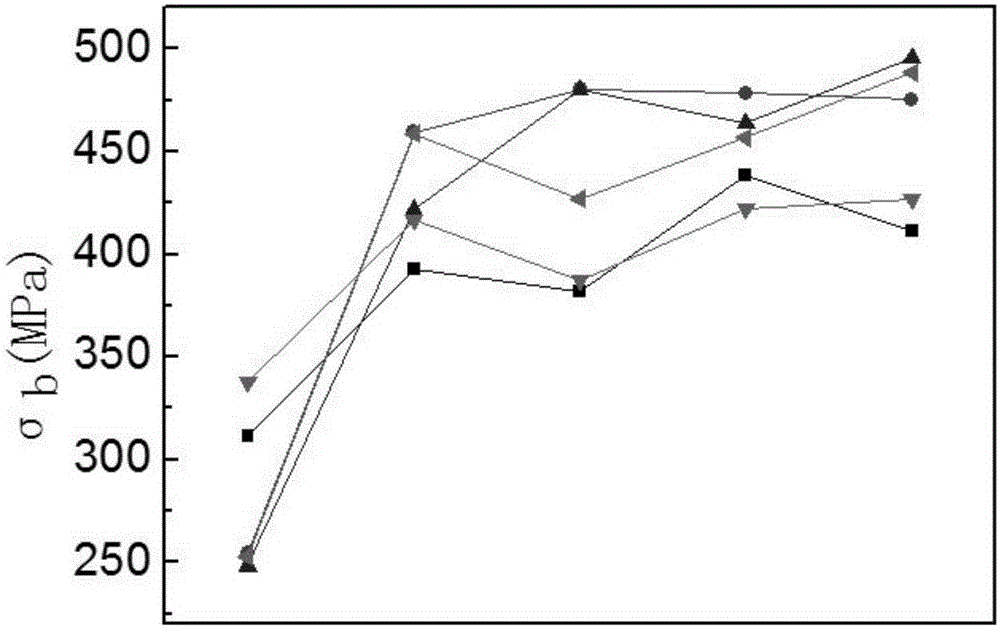

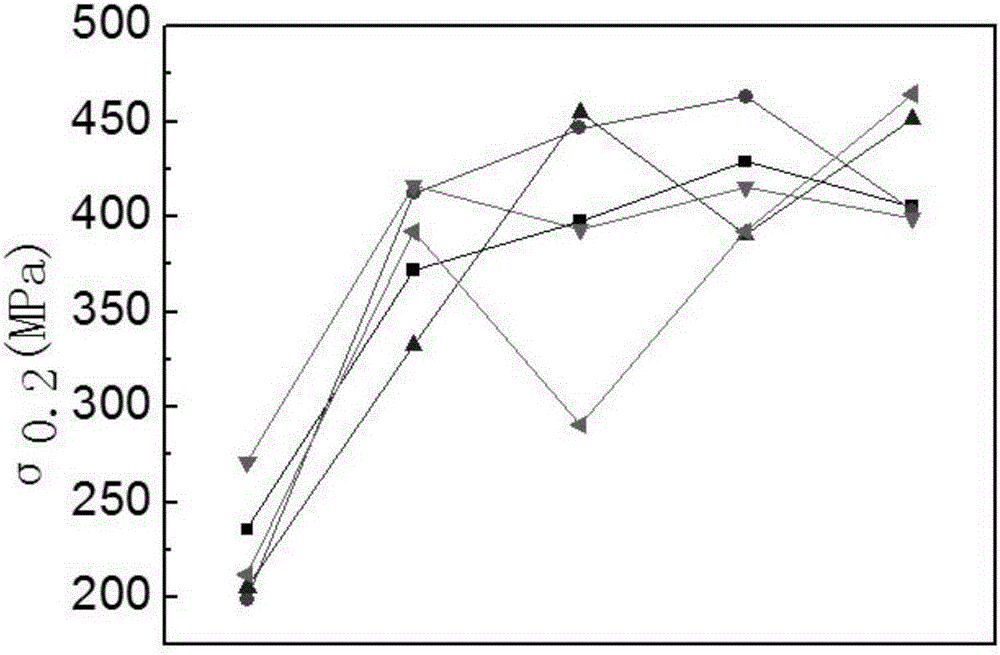

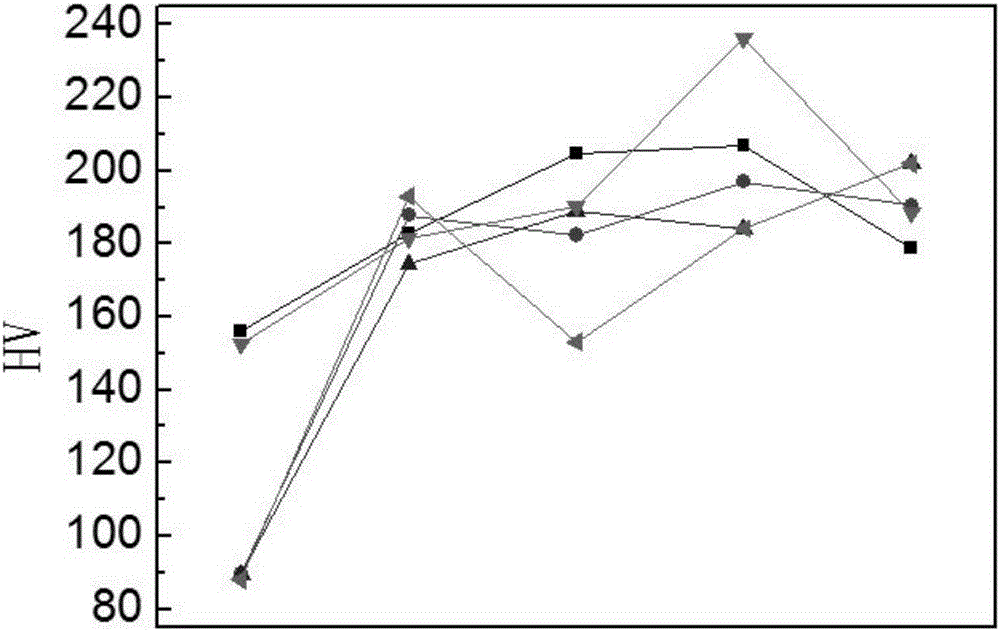

[0016] Specific implementation mode 1: In this implementation mode, the high-strength controllable elongation heat treatment method for large-scale aluminum alloy thick-walled rings is implemented according to the following steps:

[0017] 1. Use wire cutting to cut the 2A14 aluminum alloy thick-walled ring, then put it into a box-type resistance furnace, keep it warm at a temperature of 490-500°C for 1.8-2.5 hours, take out the 2A14 aluminum alloy thick-walled ring and quickly transfer it to 50 Quenching treatment is carried out in hot water at ~70°C to obtain aluminum alloy thick-walled rings after solid solution quenching;

[0018] 2. Use a three-roll rolling mill to carry out repeated hot-rolling treatment on the ring inner wall of the aluminum alloy thick-walled ring after solid solution quenching by means of ring rolling. 280°C, the rolling deformation per pass is 30% to 40%, and the hot-rolled aluminum alloy wall ring is obtained by rolling;

[0019] 3. Put the hot-rol...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the wall thickness of the 2A14 aluminum alloy thick-walled ring described in step 1 is 190-210 mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the outer diameter of the 2A14 aluminum alloy thick-walled ring described in step 1 is 1800-2000 mm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com