Domestic sewage separation and classification power generation system for high-rise buildings and its control method

A technology for domestic sewage and high-rise buildings, applied in construction, sustainable buildings, water supply installations, etc., can solve the problems of waste of organic fertilizer, reduced power generation of generators, unstable power generation current, etc., to improve mechanical efficiency and reduce pipelines. Blockage, the effect of solving system blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

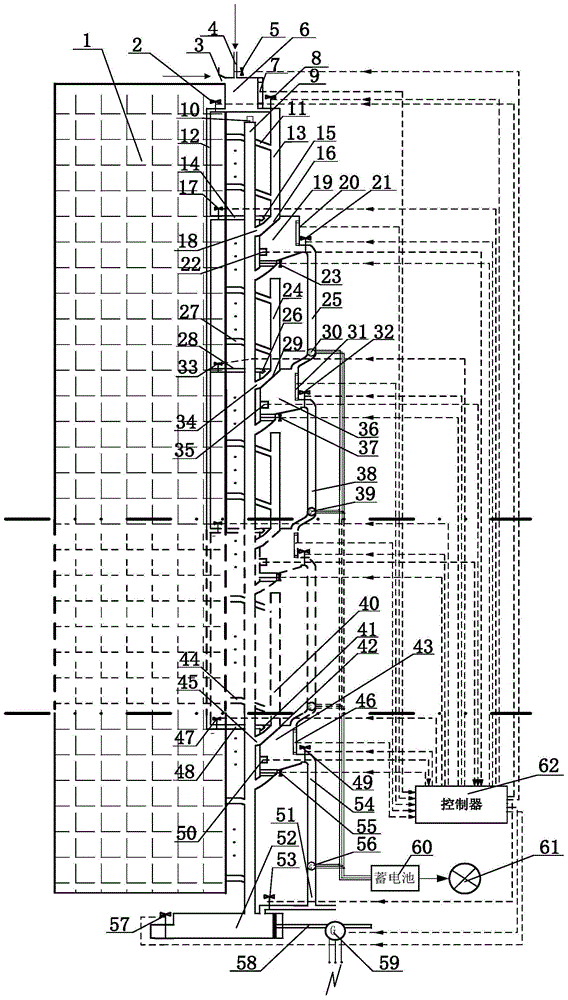

[0024] like figure 1 As shown, the high-rise building 1 itself is equipped with a vertical main sewage pipe 9 from the top to the bottom of the high-rise building 1, and the domestic sewage of each floor household where the high-rise building 1 lives is discharged to the main sewage discharge pipe through the household sewage discharge pipe of this floor. Tube 9. According to the actual number of floors of the high-rise building 1, all household sewage discharge pipes of the high-rise building 1 are divided into several levels from top to bottom, and each level of sewage discharge pipe is composed of multi-layer household sewage discharge pipes. Like this, all resident domestic sewage discharge pipes are successively divided into first-level household sewage discharge pipes 11 of each floor, second-level domestic sewage discharge pipes 27 of each floor households, and until the last level of household sewage discharge pipes of each floor from top to bottom. Tube 44. The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com