Turbine blade of blade top rib wing structure

A technology of turbine blade and wing structure, which is applied in the direction of supporting components of blades, machines/engines, mechanical equipment, etc., and can solve problems such as thermal corrosion of blade tops, reduction of heat transfer performance of blade tops, and flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

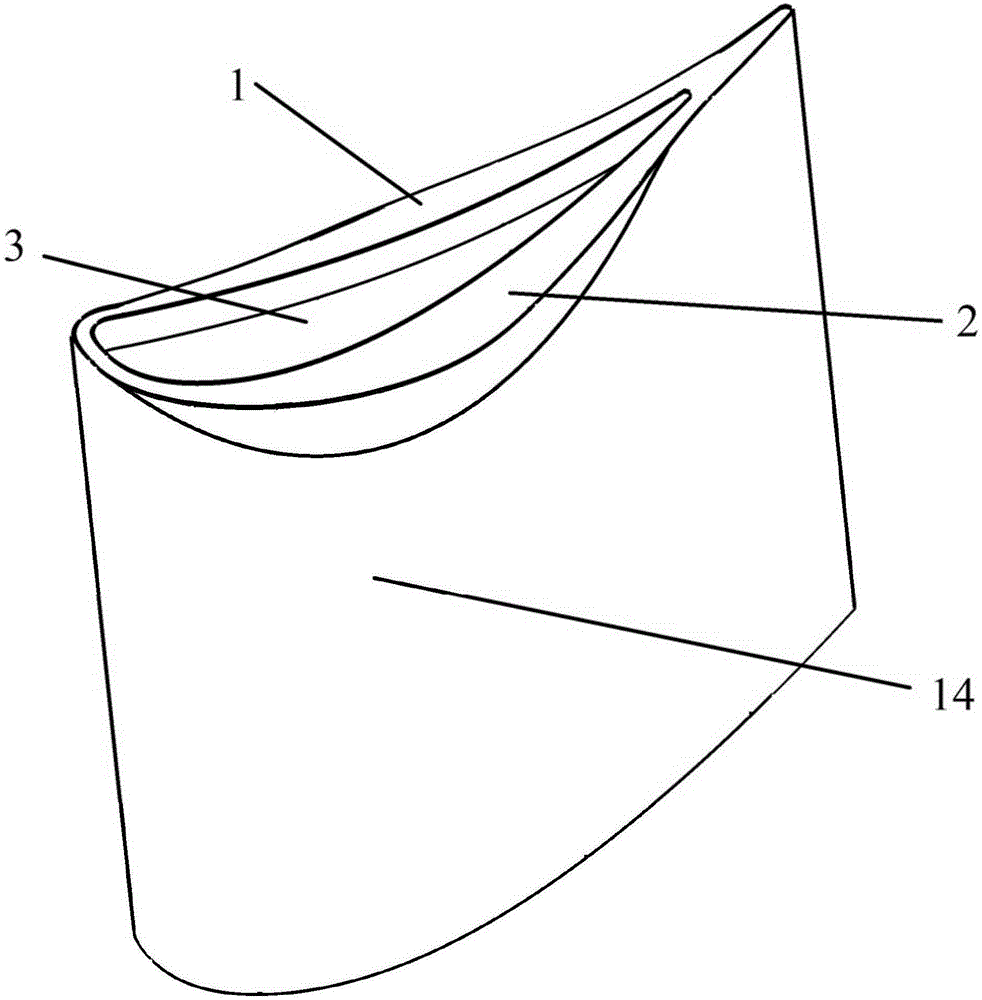

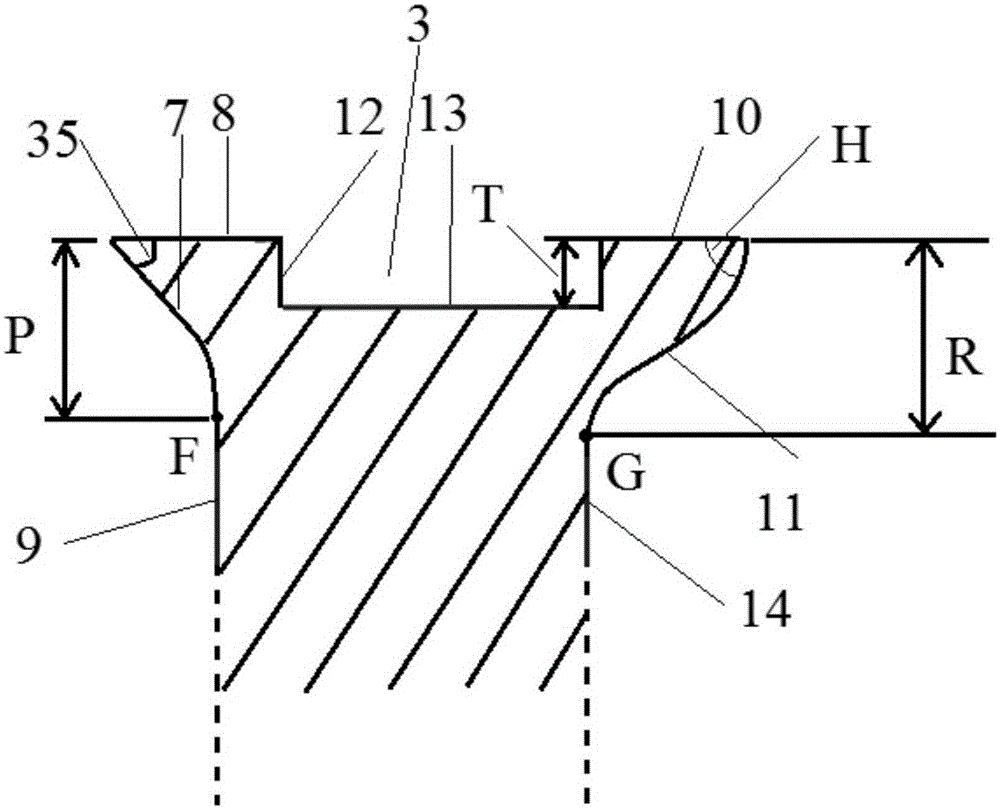

[0031] Such as figure 1 As shown, the blade tip structure of a new type of turbine rotor blade includes a blade pressure side winglet 1 and a blade suction side winglet 2, and the blade pressure side winglet 1 and the blade suction side winglet 2 are formed Cavity 3 in the middle of the leaf tip.

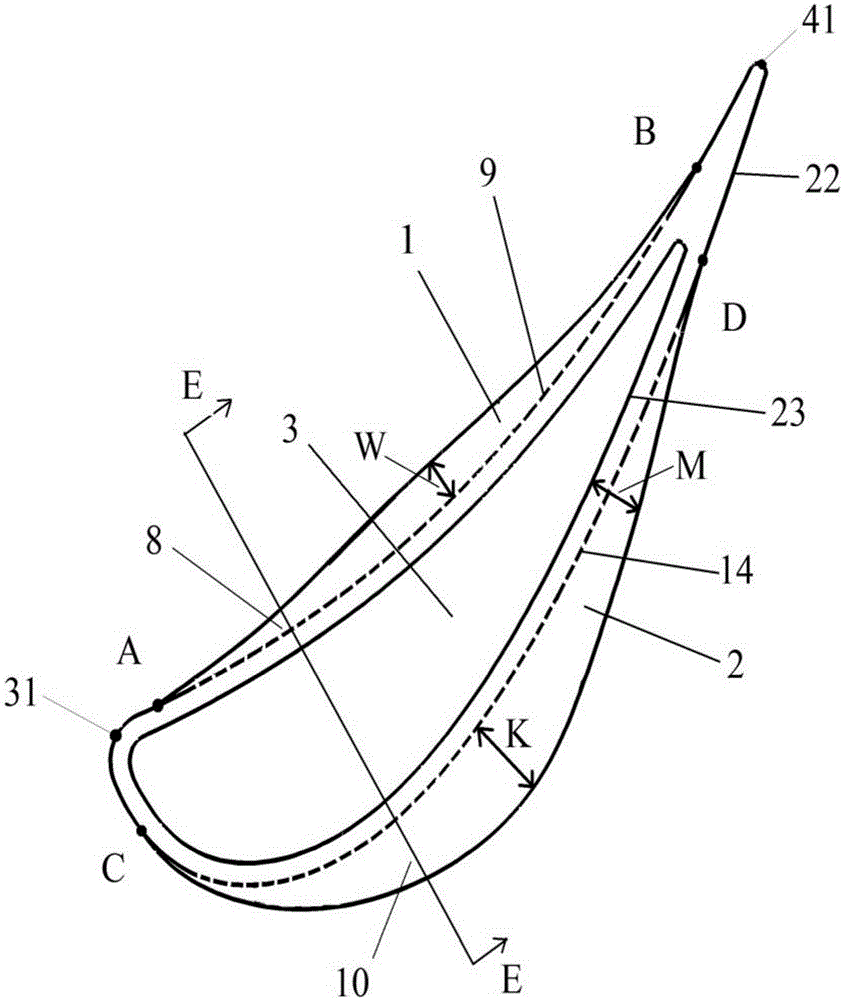

[0032] Such as figure 2 As shown, the starting point A of the pressure surface winglet 1 is close to the leading edge 31 of the blade, and the ending point B is close to the trailing edge 41 of the blade; the starting point A of the pressure surface is located on the suction surface, and the distance from the leading edge 31 of the blade is 0%-50% The length of the pressure surface, the end point B of the pressure surface is located on the pressure surface, and the distance from the blade trailing edge 41 is 40%-90% of the pressure surface length.

[0033] The wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com