High-power offshore wind generating set tower bottom cooling system and control method

A technology for wind turbines and cooling systems, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of large cooling capacity, high reliability requirements, and high cost reduction requirements, so as to improve reliability and prevent condensation. dew, the effect of maintaining the normal operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

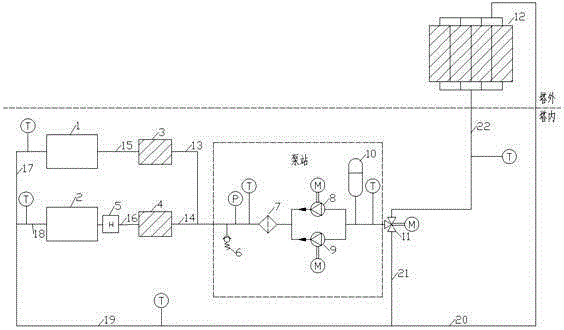

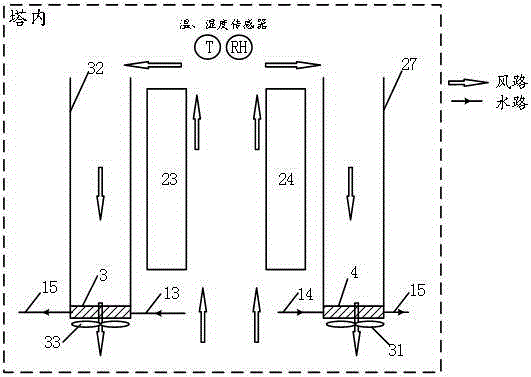

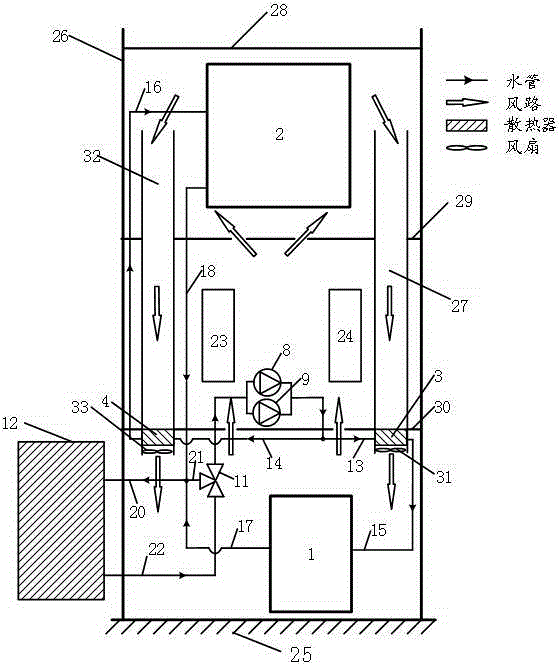

[0024] A tower bottom cooling system for high-power offshore wind turbines is mainly composed of a water cooling cycle and a closed air cooling cycle. The water cooling cycle and the air cooling cycle are integrated and coupled to comprehensively control the thermal environment of the entire tower bottom.

[0025] Such as figure 1 Shown is the schematic diagram of the water cooling cycle in the cooling system at the bottom of the tower, including main circulation pumps 8, 9, filter 7, pressure relief valve 6, heat exchangers 3, 4 in the tower, heater 5, power consumption devices 1, 2, The three-way valve 11, the external heat exchanger 12, the expansion tank 10 and the pipeline, wherein the pressure relief valve 6, the filter 7, the two main circulation pumps 8 and 9 in parallel and the expansion tank 10 are integrated in the pump station, and the thermal The exchanger 12 is located outside the tower and is connected to it by pipelines 20 and 22 passing through the tower, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com