Floating liquefied natural gas regasification system for low-temperature water area

A liquefied natural gas and floating technology, which is applied in fixed-capacity gas storage tanks, container discharge methods, gas/liquid distribution and storage, etc., can solve problems such as shortening the service life of equipment, hidden safety hazards of leakage, and corrosion of heat exchangers. Achieve the effects of high comprehensive energy utilization rate, continuous and safe gas supply, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention. In the description of the present invention, it should be understood that the terms "first", "second" and so on are only used for the purpose of description, and should not be understood as indicating or implying relative importance.

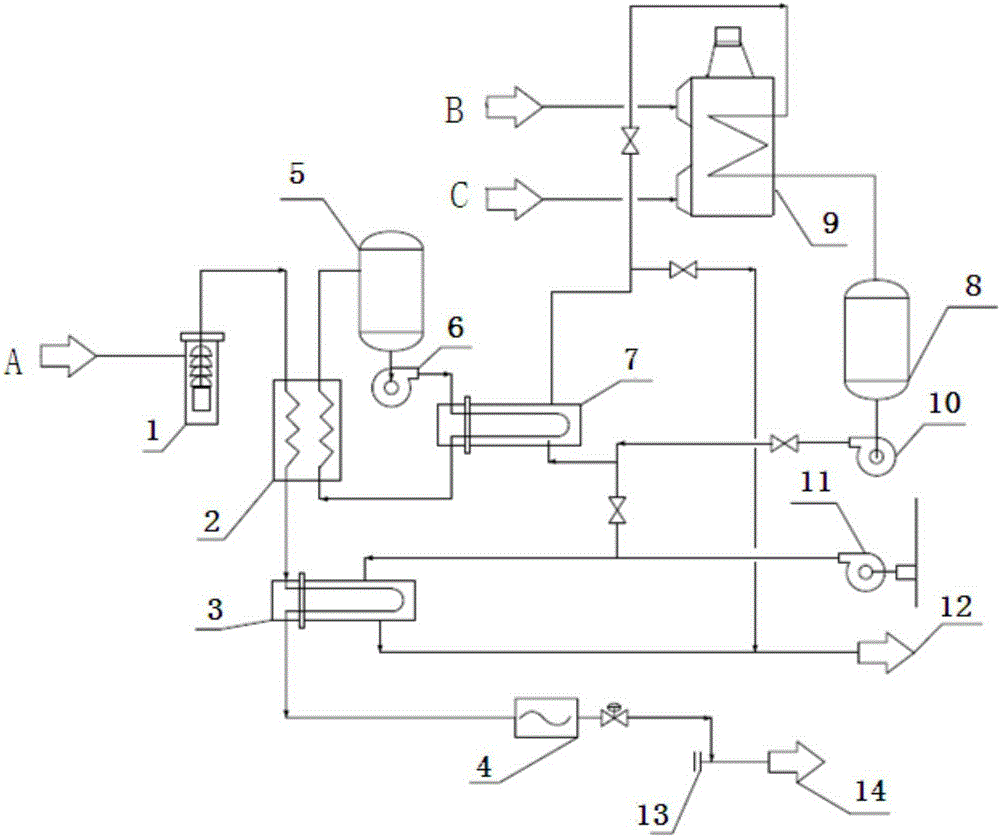

[0018] Such as figure 1 As shown, the floating liquefied natural gas regasification system for low temperature waters of the present invention includes a LNG / NG conversion structure, an intermediate medium (IF) loop structure, a heating medium (HM) loop structure and a seawater circulation structure;

[0019] The LNG / NG conversion structure includes an LNG high-pressure pump 1, the inlet of the LNG high-pressure pump 1 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com