A non-destructive testing method for bulk defects based on the combination of pulsed eddy current and electromagnetic ultrasonic

A pulsed eddy current and electromagnetic ultrasonic technology, which is applied in the analysis of solid and material magnetic variables using sonic/ultrasonic/infrasonic waves, and can solve the problem of indistinguishable echo signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

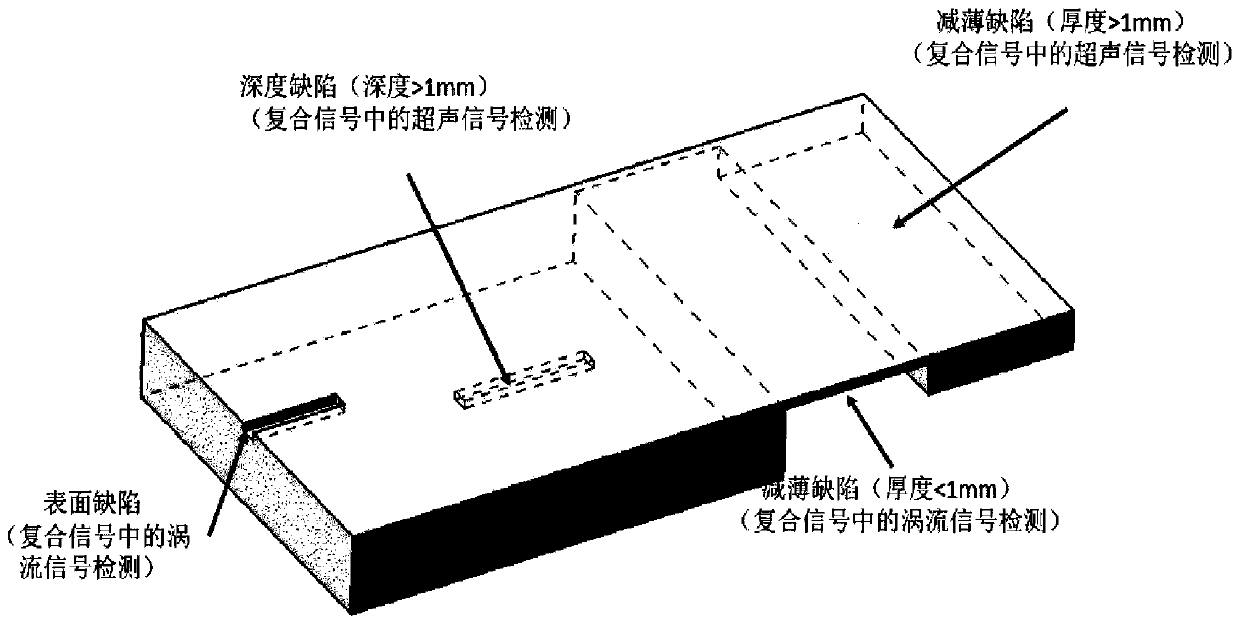

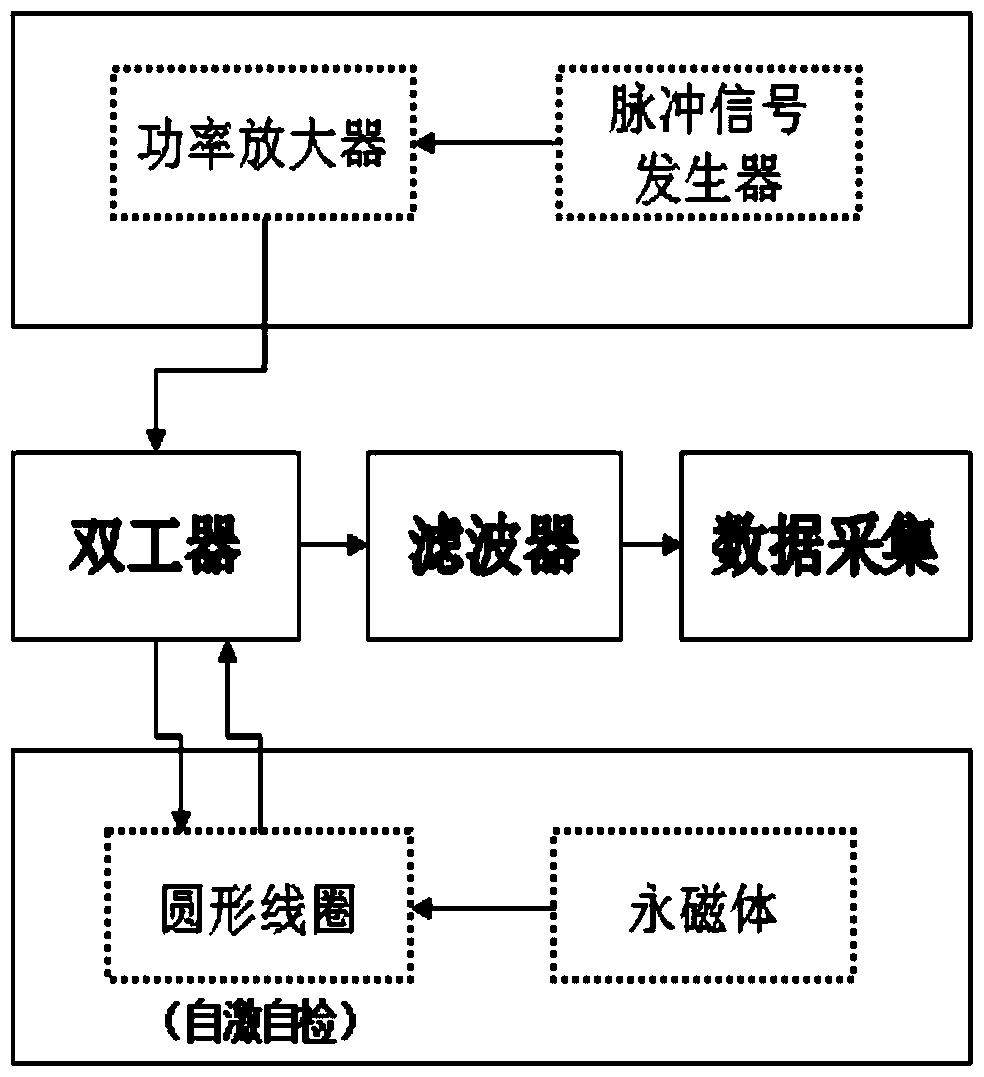

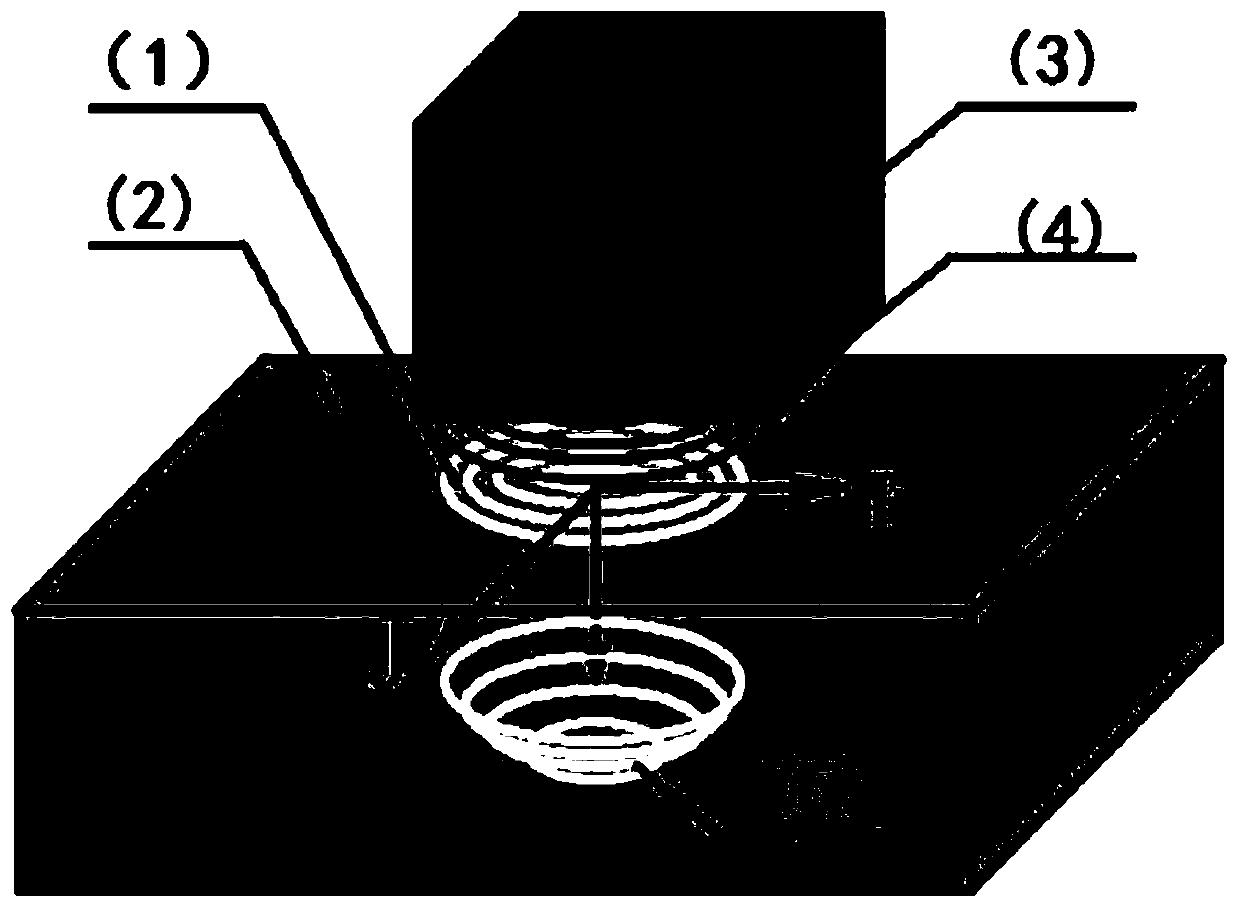

[0070] For such as figure 1 Shown different body defect types, the detection step of the inventive method is: as figure 2 , image 3 As shown, the permanent magnet 3 is placed on the circular coil 4, so that the test piece 2 is in a static magnetic field environment, the pulse eddy current device is turned on, and the circular coil 4 is excited by a pulse signal. At this time, the permanent magnet 3 and the circular coil 4 form a The electromagnetic ultrasonic / pulse eddy current composite probe senses the change of the spatial magnetic field and simultaneously obtains the detection signal, and the obtained signal is separated by the connected duplexer, connected to the filter, and the detection signal is filtered according to the numerical calculation result. The output is sent to the data acquisition device, and the data acquisition device can quantitatively detect different body defects by analyzing the signal. The working principle of the pulsed eddy current and electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com