Method of recognizing parts during maintenance process by intelligent glasses

A technology of smart glasses and recognition methods, applied in three-dimensional object recognition, computer parts, character and pattern recognition, etc., can solve problems such as water leakage, tire blowout, oil leakage, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for identifying parts in the maintenance process of smart glasses, comprising the following steps:

[0044] S1: First build an offline feature library for existing parts to support feature matching with the part information collected by subsequent smart glasses, and store the feature library in the server database module;

[0045] S2: Switch the mode of the smart glasses to the recognition mode, and take multi-angle shots of the parts to be recognized through the front camera on the smart glasses. The captured images must have overlapping parts, and the captured pictures are transmitted to the server through the communication module for 3D reconstruction , to extract spatial context features;

[0046] S3: Compare the extracted spatial context features with the part features in the offline feature library, and use the LAPJV algorithm to perform optimal matching operations on the feature matrix to minimize the cost;

[0047] S4: Select the auto part correspondin...

Embodiment 2

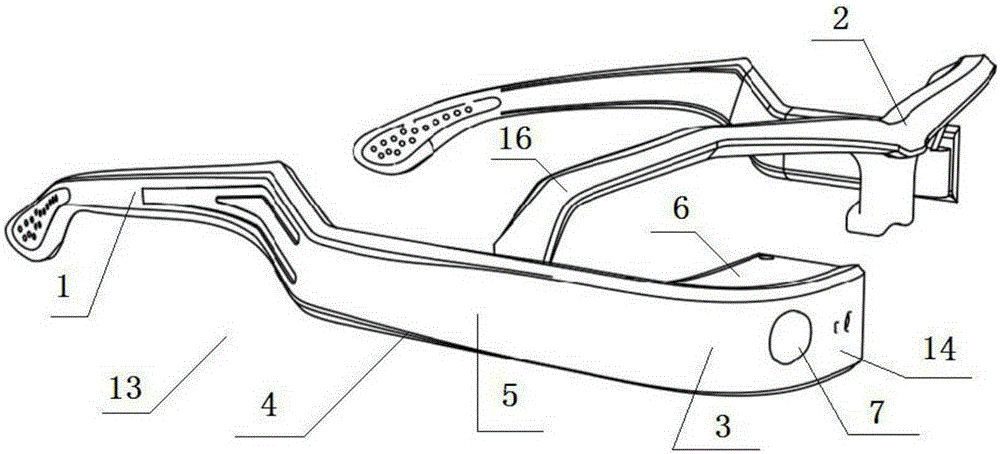

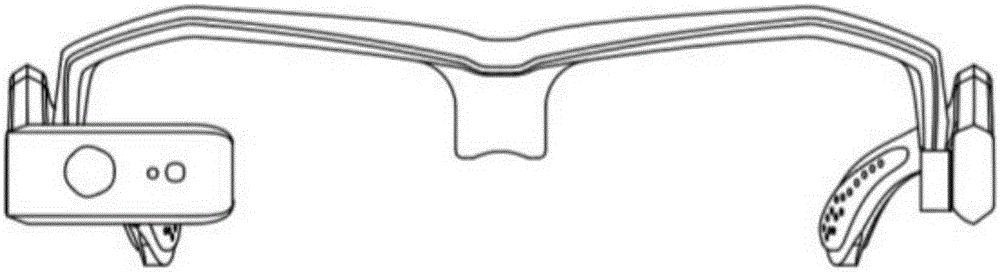

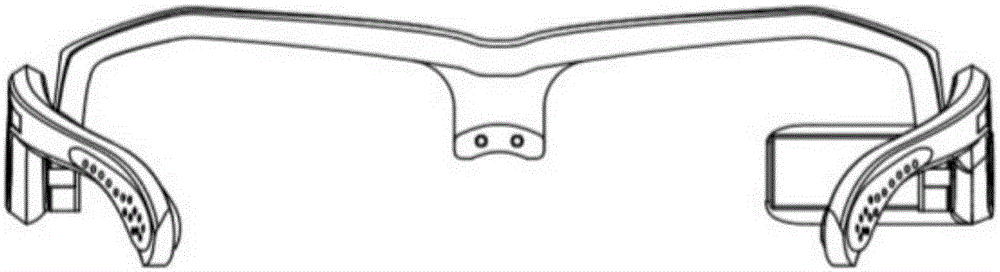

[0051] Embodiment 2: It has the same technical solution as Embodiment 1, the difference is: a light source is installed in the camera 15 accommodating portion and corresponds to the light source hole 8 on the second straight board 14, the microphone 11 is installed inside the first straight board 4, glasses Near the connection between the frame 2 and the convoluted bend; the speaker 12 is installed on the part of the temple 1 close to the ear when wearing smart glasses; the camera 15 is supported by the camera 15 bracket 9 and installed in the camera 15 accommodating part, and the gyroscope is used for Identify vibration signals and set different vibration signals to perform corresponding actions on smart glasses for car maintenance. Light sources, microphones, and speakers are multi-directional interactive means for maintenance using smart glasses, and realize a full range of intelligent interactions to improve the intelligence of smart glasses.

Embodiment 3

[0052] Embodiment 3: have the same technical scheme as Embodiment 2, the difference is: camera 15, light source, microphone 11 and loudspeaker 12 are connected to control panel 10, and this control panel 10 has wireless communication module, is used to receive camera 15, light source, The signal sent by the microphone 11 can be used for data processing on the received signal, and the control board 10 is equipped with a wireless signal transceiver module, and uses the signal transceiver module to send and receive signals to the remote server. The wireless signal includes, Wifi, Bluetooth, GPS, FM. Since the smart glasses are directly connected to the control board, the control board then performs signal interaction with the remote server, and the control board can also perform data processing on the received signal, that is, some simple recognition operations or other operations can be completely performed by the control board. Recognition or other processing, or pre-processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com