Pseudo continuous conduction mode switch converter set follow current duty ratio control method and apparatus

A pseudo-continuous conduction, mode switching technology, applied in output power conversion devices, conversion equipment without intermediate conversion to AC, electrical components, etc., can solve problems such as the limitation of the load range of the converter, and achieve enhanced stability and dynamic response. capability, improve transient performance and efficiency, and ensure the effect of steady-state performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

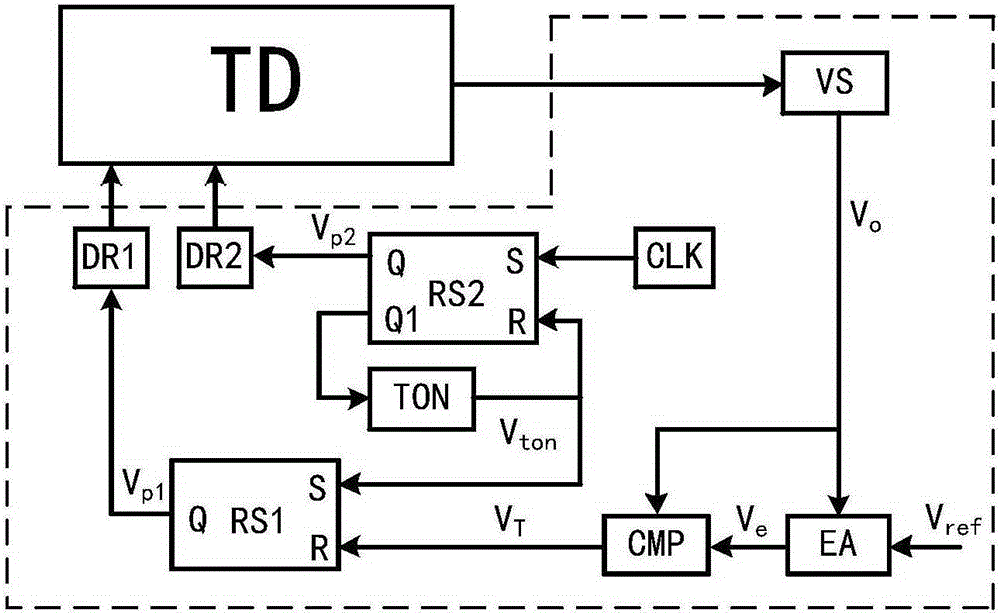

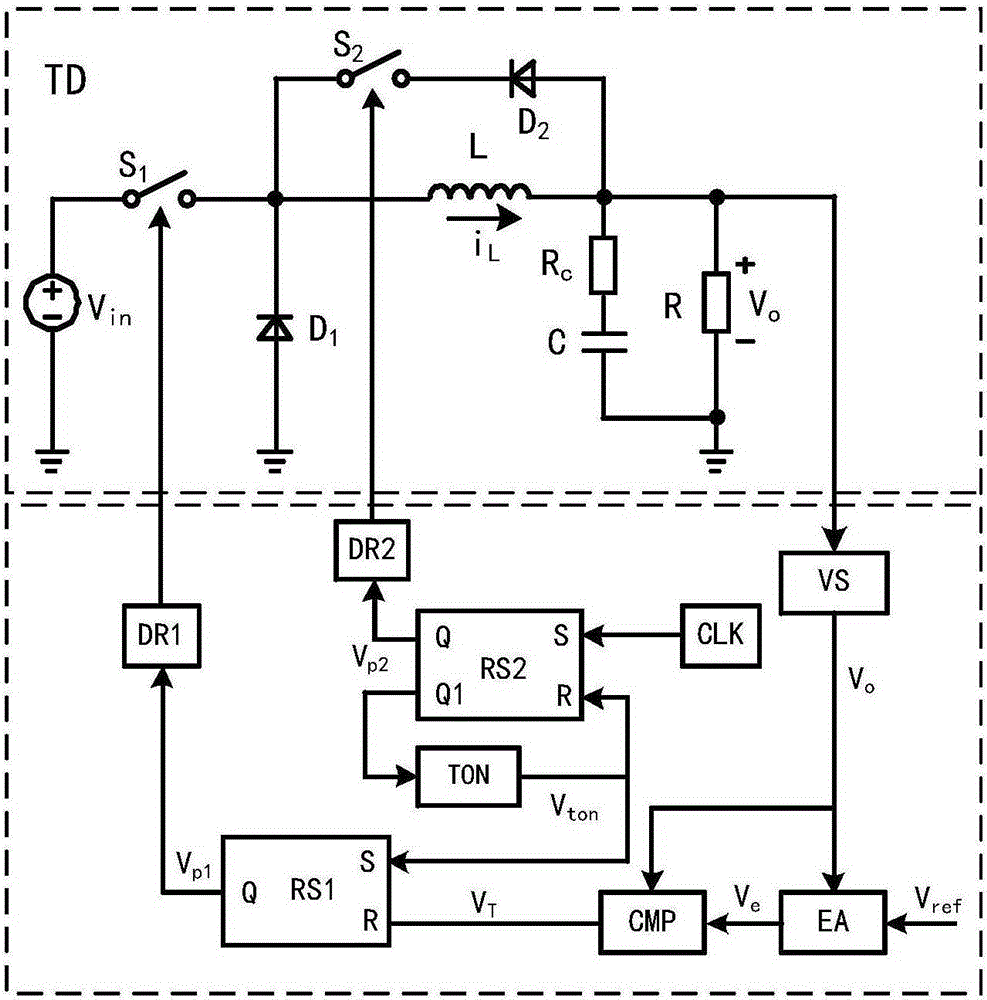

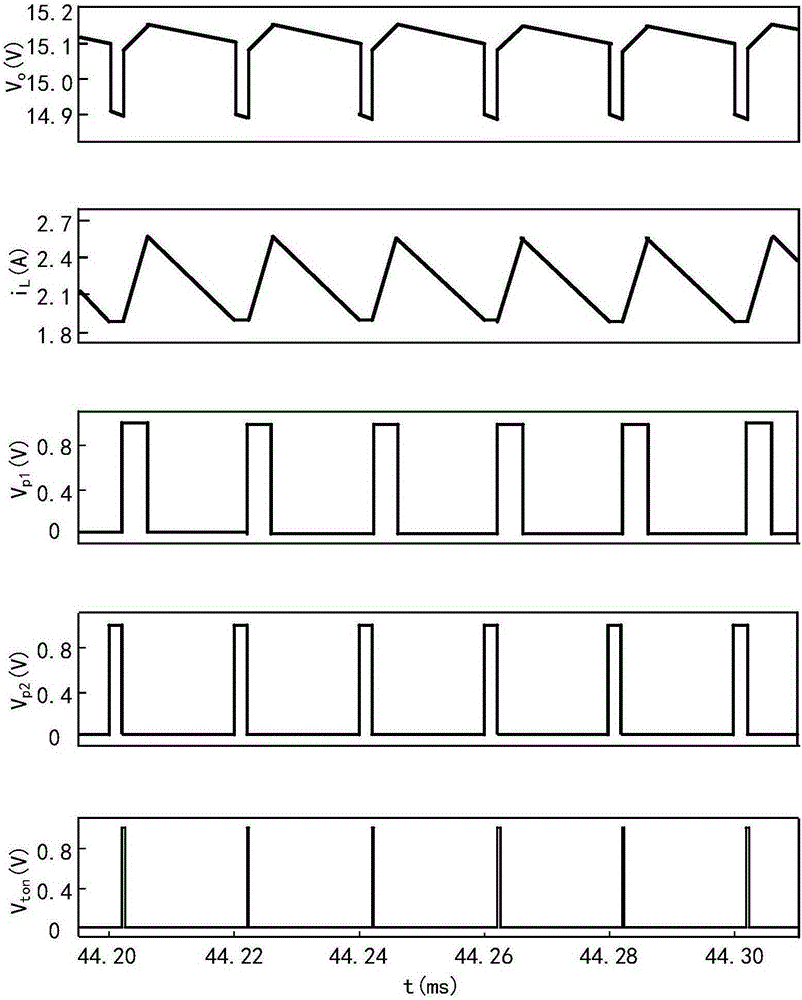

[0032] figure 1It is shown that a specific embodiment of the present invention is: a pseudo-continuous conduction mode switching converter constant current duty ratio control device, which is mainly composed of a voltage detection circuit VS, an error amplifier EA, a first trigger RS1, a second trigger RS2, a comparator CMP, a conduction timer TON, a clock signal CLK, a first driving circuit DR1 and a second driving circuit DR2. The voltage detection circuit VS is used to detect the output voltage V o value; the error amplifier EA is used to reference the voltage V ref and the output voltage V o The difference signal is amplified to generate the control voltage V e ;Comparator CMP is used to compare the output voltage V o and control voltage V e The size of the first flip-flop RS1 generates a reset signal; the first flip-flop RS1 is used to obtain the pulse signal V p1 , through the first drive circuit DR1 to control the turn-on and turn-off of the main switch tube; the ...

Embodiment 2

[0046] Such as Figure 8 As shown, this example is basically the same as the first example, except that the converter TD controlled in this example is a PCCM single-ended forward converter.

[0047] In addition to the switching converters in the above embodiments, the present invention can also be used in PCCM converter topologies such as PCCM half-bridge converters and PCCM full-bridge converters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com