Ferritic stainless steel foil for solar cell substrates

A technology of solar cells and stainless steel foils, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of deep drawing, breaking, wrinkling, etc., and achieve the effect of excellent passability and wrinkle suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

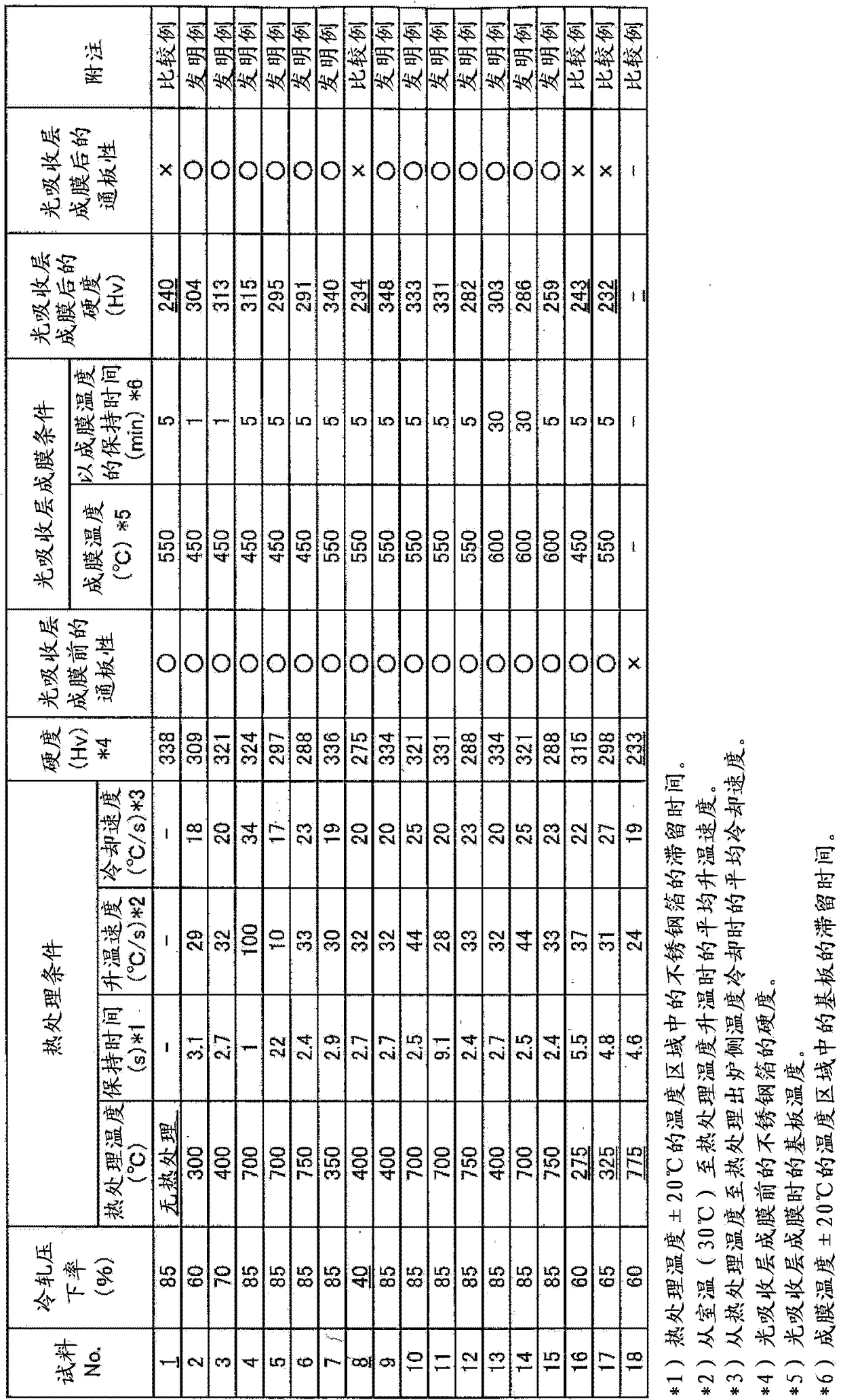

[0106] For the solar cell substrate, when the solar cell unit is manufactured using the roll-to-roll method, it is required to have excellent heat resistance that can suppress the softening caused by the film formation process of the light-absorbing layer, and to have the ability to suppress the softening of the substrate afterward. Excellent plate passability in which wrinkles caused by buckling and the like appear. This is because in a continuous process such as the roll-to-roll method, if wrinkles or the like are generated on the substrate when passing the sheet, the productivity and photoelectric conversion efficiency of the solar cell will decrease.

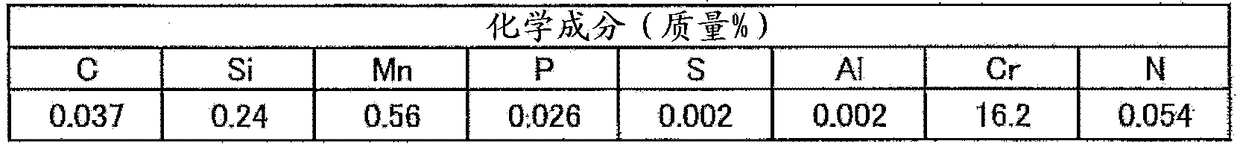

[0107] Therefore, in view of the above-mentioned required characteristics, samples of stainless steel foil for solar cell substrates were produced, and various tests for evaluating the above-mentioned characteristics were implemented. The preparation method of the sample and various test / evaluation methods are as follows.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com