Method for preparing radix astragali extracting solution

An astragalus extract and the technology of the extract, which are applied in the field of preparation of astragalus extract, can solve problems such as poor stability and less active ingredient retention, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

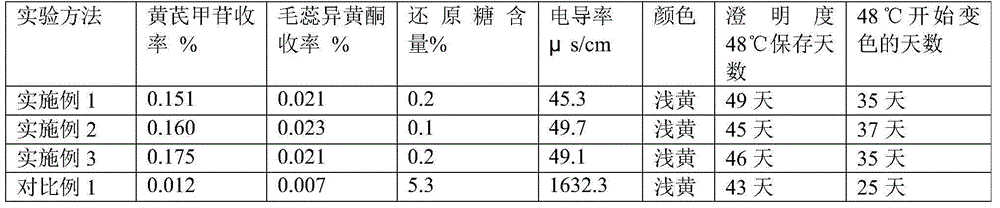

Examples

Embodiment 1

[0036] The present embodiment provides a preparation method of astragalus extract, the preparation method comprising the following steps:

[0037] Extraction: Astragalus decoction pieces are boiled for 2 hours with 6 times of water, and the dregs are boiled for 1 hour with 4 times of water, and the extracts are combined;

[0038] Microfiltration: the extract is filtered with a 1μm ceramic membrane, and the filtrate is filtered with a 0.2μm ceramic membrane at a pressure of 10bar;

[0039] Ultrafiltration: The filtrate is ultrafiltered with a membrane with a molecular weight cut-off of 10000D, the operating pressure is 3bar, and when the ultrafiltration is about 30% of the reflux liquid, add the same amount of water and continue the ultrafiltration until the amount of the exudate is equal to the initial extraction liquid;

[0040] Membrane concentration: ultrafiltration exudate is concentrated with a membrane with a molecular weight cut-off of 100-200D, the operating pressure i...

Embodiment 2

[0045] The present embodiment provides a preparation method of astragalus extract, the preparation method comprising the following steps:

[0046] Extraction: Astragalus decoction pieces were boiled for 3 hours with 5 times of water, the dregs were boiled for 1 hour with 6 times of water, and the extracts were combined;

[0047] Microfiltration: the extract is filtered with a 0.45μm ceramic membrane, and the filtrate is filtered with a 0.1μm ceramic membrane at a pressure of 15bar;

[0048] Ultrafiltration: The filtrate is ultrafiltered with a membrane with a molecular weight cut-off of 8000D, the operating pressure is 6bar, and when the ultrafiltration reaches about 20% of the reflux liquid, add the same amount of water and continue the ultrafiltration until the amount of the exudate is equal to the initial extraction liquid;

[0049] Membrane concentration: ultrafiltration exudate is concentrated with a membrane with a molecular weight cut-off of 100-200D, the operating pres...

Embodiment 3

[0054] The present embodiment provides a preparation method of astragalus extract, the preparation method comprising the following steps:

[0055] Extraction: Astragalus decoction pieces are boiled for 2 hours with 8 times of water, and the dregs are boiled for 2 hours with 3 times of water, and the extracts are combined;

[0056] Microfiltration: the extract is filtered with a 1μm ceramic membrane, and the filtrate is filtered with a 0.2μm ceramic membrane at a pressure of 12bar;

[0057] Ultrafiltration: The filtrate is ultrafiltered with a membrane with a molecular weight cut-off of 10000D, the operating pressure is 4bar, and when the ultrafiltration is about 30% of the reflux liquid, add the same amount of water and continue the ultrafiltration until the amount of the exudate is equal to the initial extraction liquid;

[0058] Membrane concentration: ultrafiltration exudate is concentrated with a membrane with a molecular weight cut-off of 150D, the operating pressure is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com