Purification method of crude oil and cleaning method of oil storage tank

An oil storage tank and crude oil technology, which is applied in chemical instruments and methods, cleaning methods and utensils, mixing methods, etc., can solve the problems of reducing the utilization rate of storage tanks, affecting the quality of crude oil, inability to separate moisture and impurities, and achieving clean and discharge, improve quality, and increase the effect of oil storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

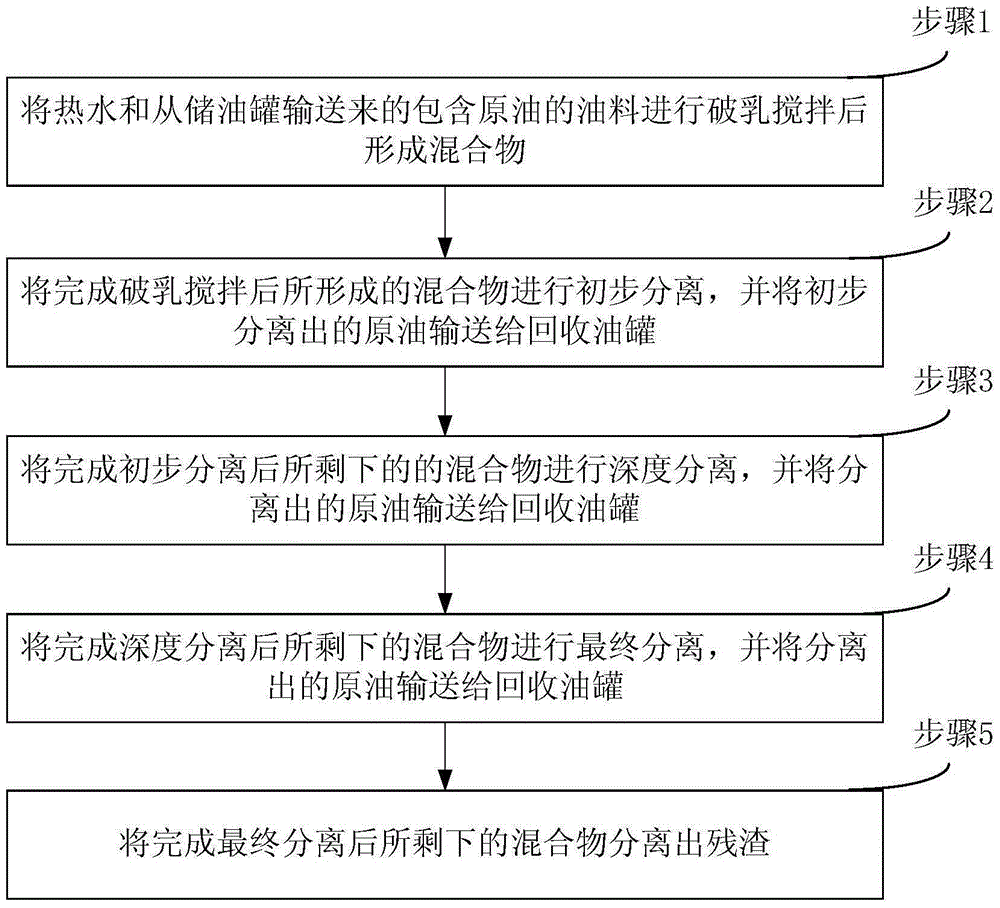

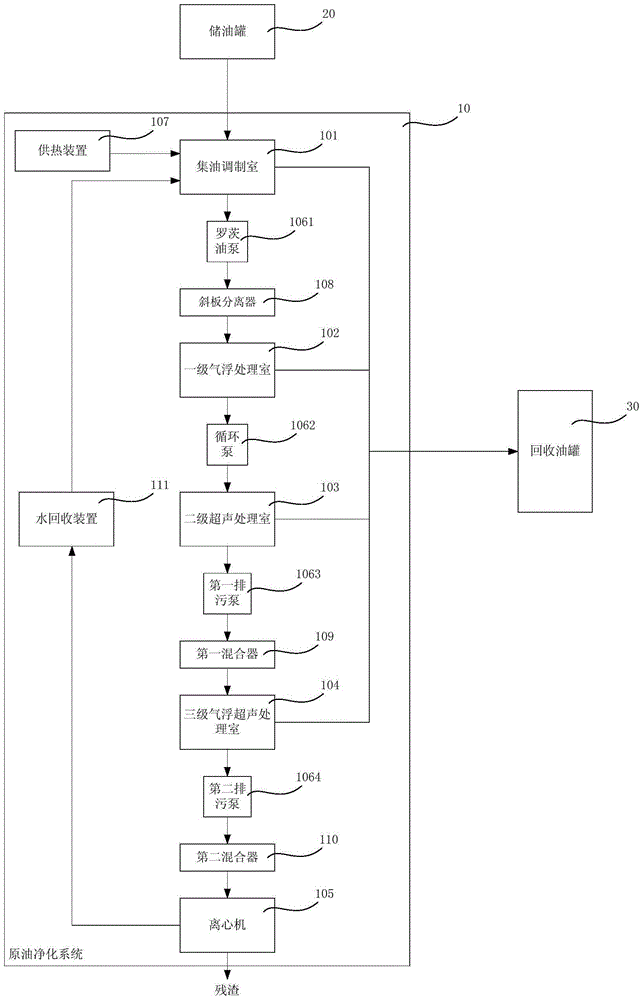

[0045] Such as figure 1 Shown, the crude oil purification method embodiment provided by the present invention comprises the following steps:

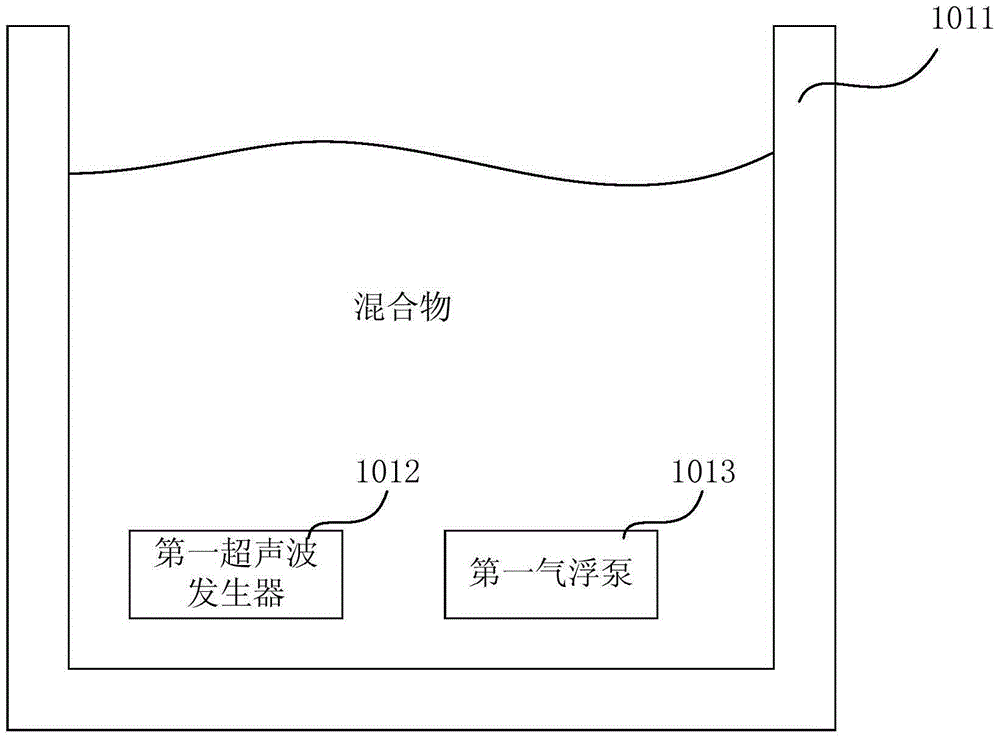

[0046] Step 1, the hot water and the oil containing crude oil transported from the oil storage tank are subjected to demulsification and stirring to form a mixture;

[0047] Step 2. Preliminary separation of the mixture formed after the demulsification and stirring is completed, and the preliminary separated crude oil is delivered to the recovery oil tank;

[0048] Step 3, performing deep separation on the remaining mixture after the preliminary separation, and transporting the separated crude oil to the recovery oil tank;

[0049] Step 4. Final separation of the remaining mixture after the deep separation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com