Floating frame driving type flip-flop screen

A driving type, relaxation screen technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of easy agglomeration, difficult screening, large force on the vibrator, etc., to achieve wide practicability and long service life Long, smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] Floating frame driven type relaxation screen of the present invention, its preferred embodiment is:

[0011] Including fixed screen frame, floating screen frame, elastic screen surface, shear spring and eccentric exciter;

[0012] The screen surface beams of the fixed screen frame and the screen surface beams of the floating screen frame are alternately arranged, and the fixed screen frame has one more screen surface beam than the floating screen frame, and one end of the elastic screen surface is fixed on the screen surface beam of the fixed screen frame , the other end is fixed on the screen beam of the floating screen frame, the two screen frames are connected together by shear springs, and the fixed screen frame is installed on the machine frame by damping springs.

[0013] The eccentric vibrator is an eccentric block or eccentric shaft structure, and its rotating shaft or eccentric shaft is installed on the screen surface beam near the centroid of the floating scre...

specific Embodiment

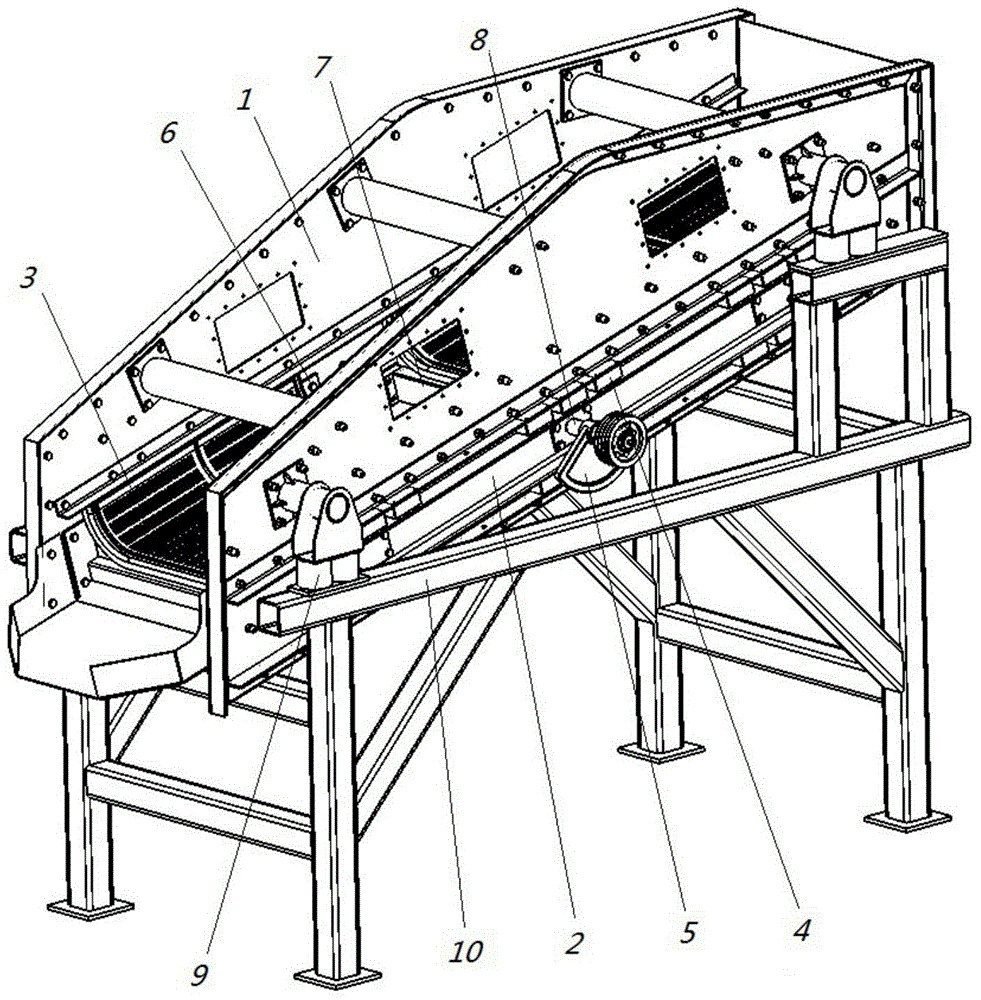

[0020] like figure 1 As shown, it includes a fixed screen frame 1, a floating screen frame 2, an elastic screen surface 3, a shear spring 4 and an eccentric vibrator 5. The screen beams 7 of the floating screen frame 2 pass through the holes on the side plate of the fixed screen frame 1 and are alternately arranged with the screen beams 6 of the fixed screen frame 1. The elastic screen surface 3 is installed on the screen beams 6 and 7, The fixed screen frame 1 and the floating screen frame 2 are connected together by a shear spring 4 , and the fixed screen frame 1 is installed on a frame 10 by a damping spring 9 .

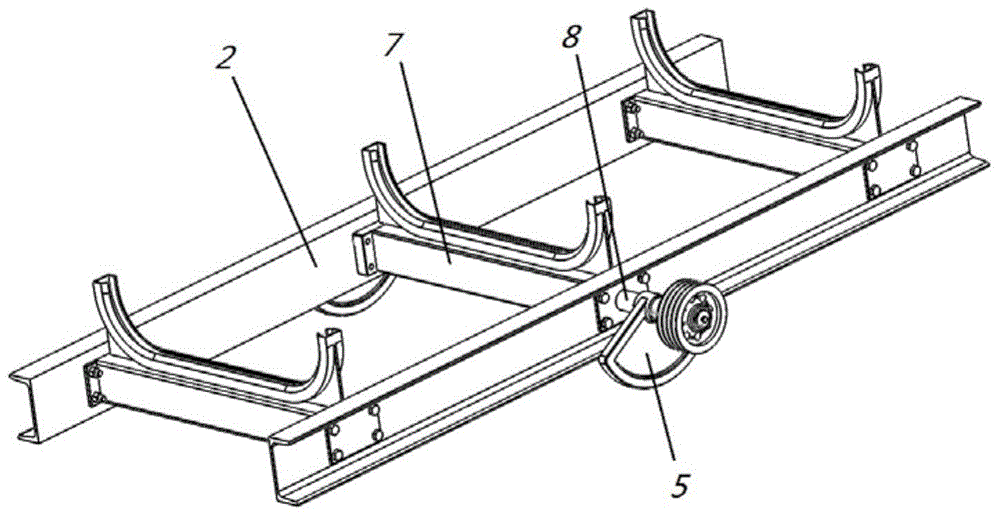

[0021] like figure 2 As shown, the rotating shaft 8 of the eccentric vibrator 5 passes through the screen beam 7 near the center of mass of the floating screen frame 2 and is fixed on the beam through a bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com