Supersonic vibrating auxiliary plastic forming device

A technology of plastic forming and ultrasonic vibration, applied in forming tools, metal processing, metal processing equipment, etc., to achieve high processing accuracy, compact structure, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

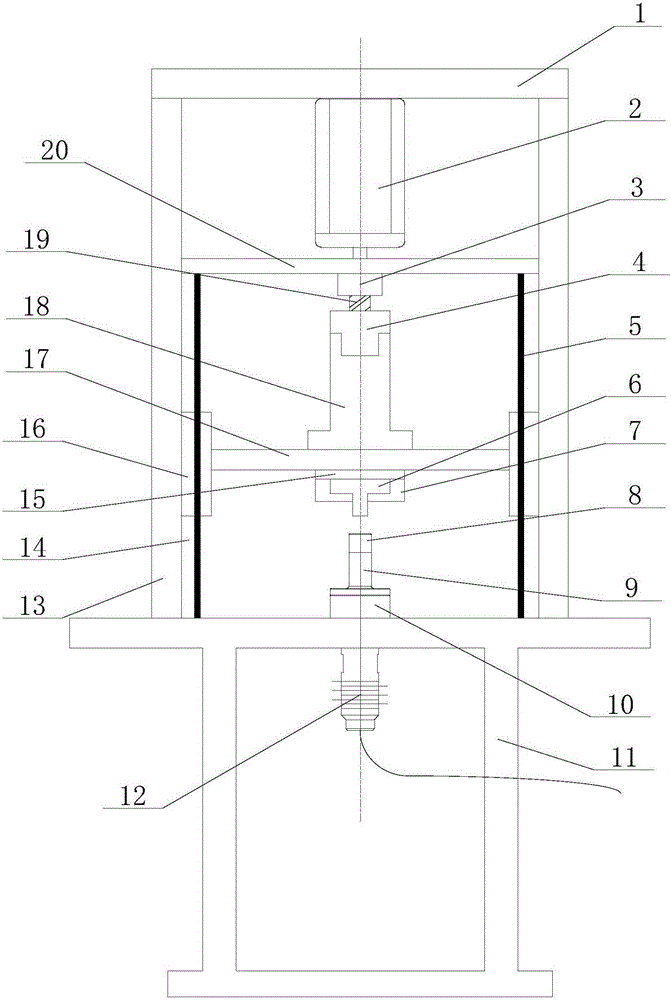

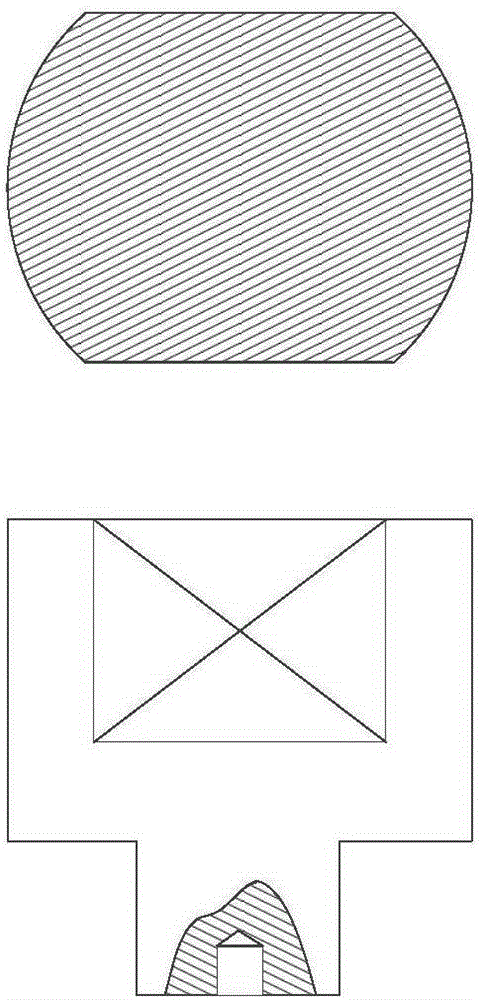

[0016] See attached figure 1 , ultrasonic vibration assisted plastic forming device, which includes: mechanical body, servo motor 2, precision grating ruler 5, upper mold 6, upper mold sleeve 7, lower mold 8, ultrasonic horn 9, ultrasonic transducer 12 and pressure sensor 15;

[0017] The mechanical body includes: platform base 11, upper beam 1, column 13, middle fixed beam 20 and movable beam 17; wherein, the platform base 11 is welded by steel pipe and steel plate, two columns 13 are vertically fixed on the platform base 11, and the column The top of the 13 is provided with an upper beam 1, the inside of the two columns 13 is provided with a guide rail 14, the precision grating ruler 5 is arranged on the inside of the guide rail 14, the middle fixed beam 20 is installed on the top of the two guide rails 14, and the movable beam 17 passes through the slider 16 connected to rail 14;

[0018] The servo motor 2 is installed in the middle of the upper beam 1, its main shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com