Nickel-base welding wire dissimilar metal cold wire TIG all-position welding method

A welding method and technology of dissimilar metals, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of easy occurrence of pores, unfused, long cycle, etc., to ensure welding quality and reduce welding cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

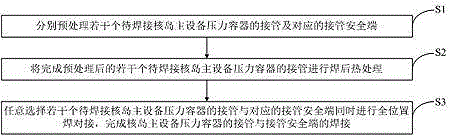

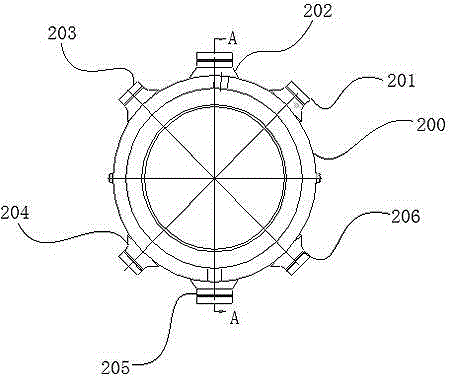

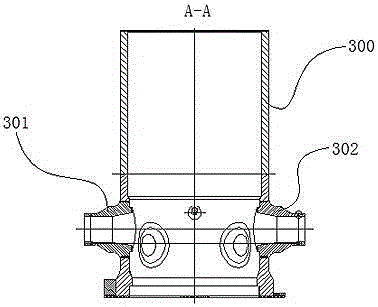

[0038] Such as figure 1 As shown, a nickel-based welding wire dissimilar metal cold wire TIG all-position welding method is used in the welding process of the main equipment pressure vessel of the nuclear island and the welding process of the safety end of the joint. In this embodiment, the pressure vessel of the main equipment of the nuclear island is AP1000 type or For the main equipment pressure vessel of Hualong No.1 nuclear island, the welding method includes the following steps:

[0039] S1. Respectively pre-process the connection pipes of the main equipment pressure vessels of the nuclear island to be welded and the corresponding safety ends of the connection pipes;

[0040] S3. Randomly select several nozzles of the pressure vessel of the main equipment of the nuclear island to be welded and carry out al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com