Oil press

A technology of oil presses and oil cylinders, applied in the field of oil presses, which can solve the problems of large mechanical wear, high oil output rate, and low profit, and achieve the effect of complete motors and electrical appliances, high oil output rate, and pure oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

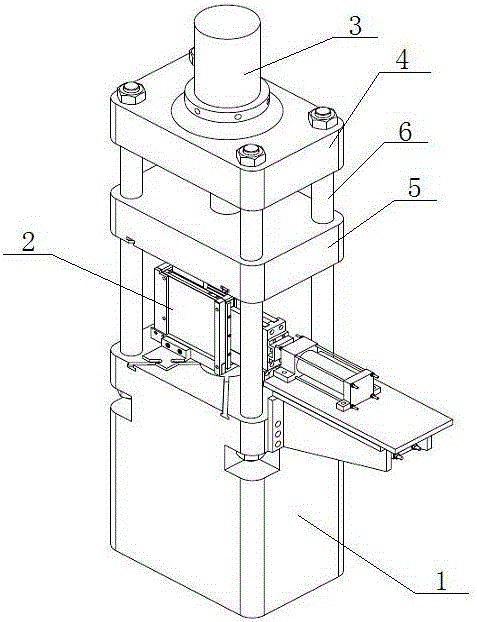

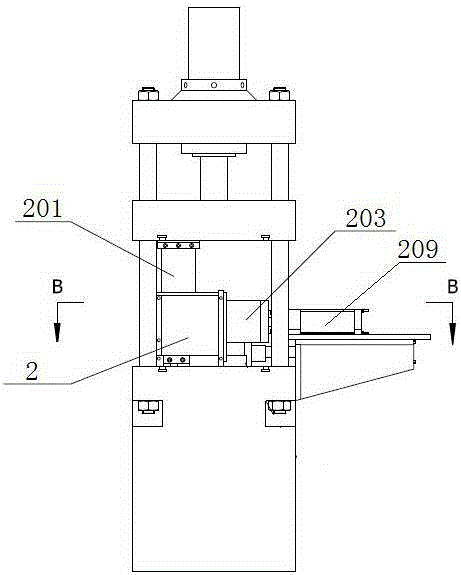

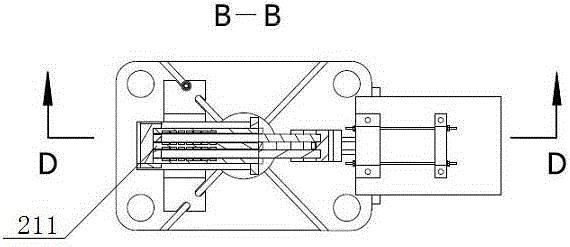

[0023] Such as Figure 1 to Figure 10 As shown, the oil press includes a base platform 1, an oil extraction box 2, an oil extraction cylinder 3, a fixed block 4, a moving block 5 and a guide post 6, and the oil extraction box 2 is installed on the base platform 1, and fixed The block 4 and the moving block 5 are connected to the base platform 1 through the guide column 6 in turn, the oil extraction cylinder 3 is connected to the fixed block 4 and the moving block 5, and the oil extraction square box 2 includes an oil extraction pressing plate 201 and an oil extraction side plate 202 , pre-pressing plate 203, top slag plate 204, oil pressing plate 205, square box rear plate 206, square box bottom plate 207, square box front plate 208, pre-pressing oil cylinder 209, top slag oil cylinder 210 and supporting keel 211, oil pressing side plate 202 and the oil pressing plate 205 are arranged and installed in the box formed by the square box rear plate 206, the square box bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com