Chassis for medium-sized pure electric bus

A pure electric bus and chassis technology, applied in the direction of electric power unit, power unit, vehicle parts, etc., can solve the problems affecting the power performance and mileage of electric vehicles, battery voltage reduction, battery performance impact, etc., to achieve simple structure, Improve performance, good balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

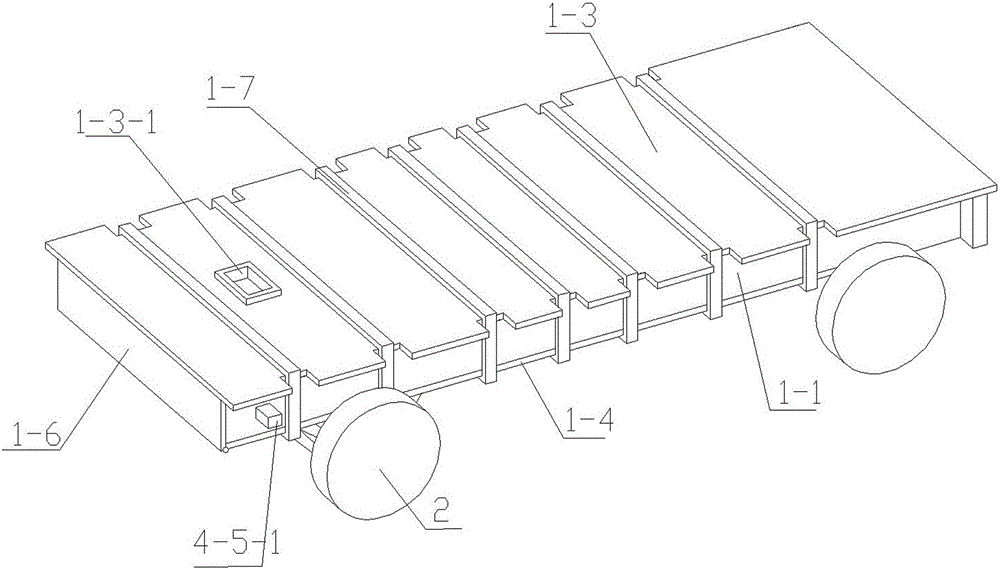

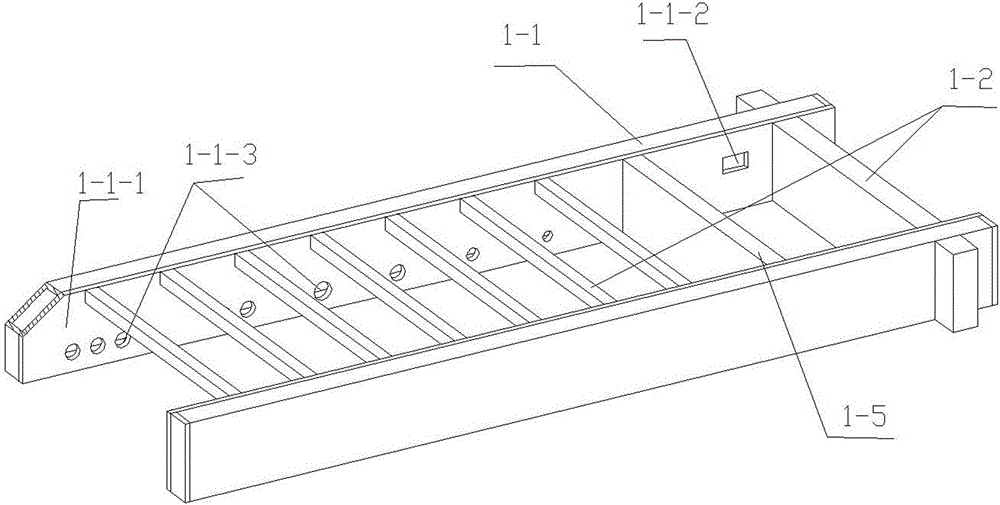

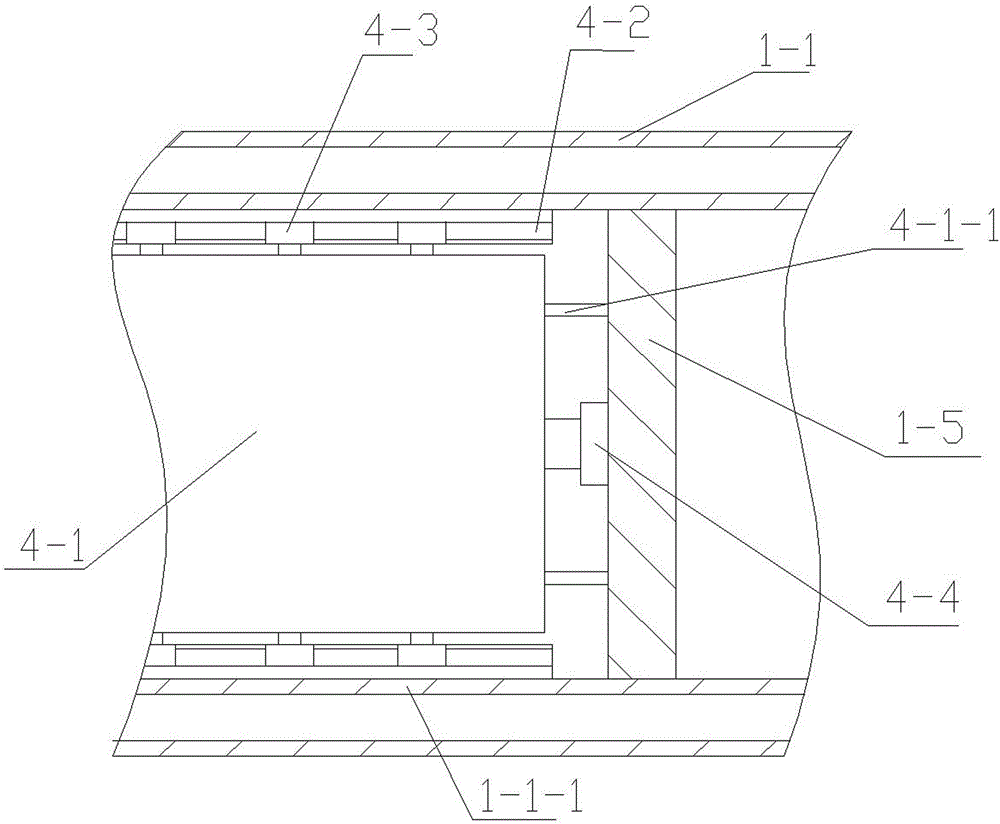

[0024] See attached Figure 1-6 , a chassis for a medium-sized pure electric bus, the structure includes a main body load-bearing frame of the chassis supporting the weight of the vehicle body, and a wheel assembly 2, a driving mechanism 3, a steering assembly, a brake assembly and an insurance vehicle arranged on the main body load-bearing frame of the chassis The main body load-bearing frame of the chassis is composed of side longitudinal beams 1-1 and cross beams 1-2, and the middle and rear structure of the main body load-bearing frame of the chassis is designed as a flat warehouse-type frame; the side longitudinal beams 1-1 are The channel steel, or the cavity-shaped square steel formed by the side sealing plate 1-1-1, combined with the sealing structure at the front and rear ends of the side longitudinal beam 1-1 forms a hollow cavity structure, and the front end is provided with an air inlet 1-1-2, The air outlets 1-1-3 are evenly distributed on the side sealing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com