Low thermal expansion material Fe2W3O12 and solid-phase sintering method thereof

A fe2w3o12, low thermal expansion technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Low thermal expansion material Fe 2 W 3 o 12 The solid phase sintering method, the steps are as follows:

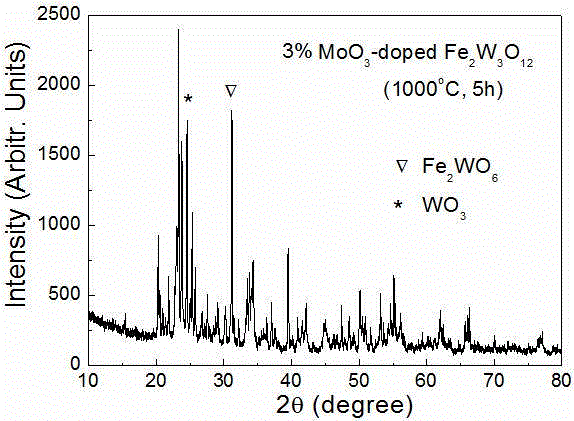

[0023] Fe 2 o 3 and WO 3 The raw material is weighed according to the stoichiometric molar ratio of 1:3, according to WO 3 3% of the molar weight is added to MoO 3 , put it into a mortar and grind for 2 hours, and press it into a cylinder with a diameter of 10 mm and a height of 10 mm with a uniaxial tablet press at a pressure of 200 MPa. Put it into a box-type furnace, raise the temperature to 1000°C for sintering for 5 hours, and then cool it down to room temperature naturally in the air. For the phase analysis of the XRD pattern corresponding to the product, see figure 1 , figure 1 The XRD results show the formation of monoclinic phase Fe 2 W 3 o 12 , containing a small amount of Fe 2 WO 6 and unreacted WO 3 .

Embodiment 2

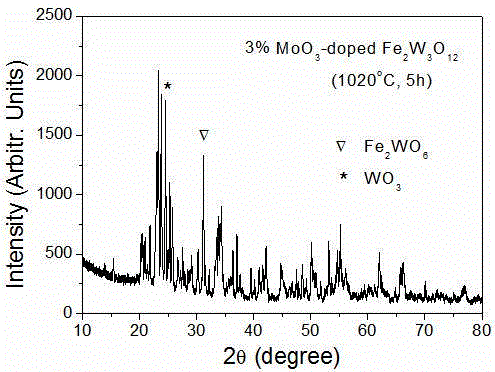

[0025] The difference from Example 1 is that: the chamber furnace was heated to 1020° C. for sintering for 5 hours. For the phase analysis of the XRD pattern corresponding to the product, see figure 2 , figure 2 The XRD results showed that more monoclinic phase Fe was formed 2 W3 o 12 , there is still a small amount of Fe 2 WO 6 and WO 3 .

Embodiment 3

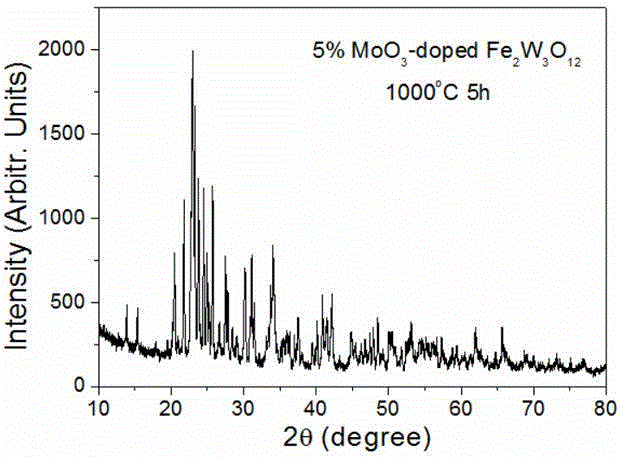

[0027] The difference from Example 1 is: adding MoO 3 The amount of WO 3 5% of the molar weight. For the phase analysis of the XRD pattern corresponding to the product, see image 3 , image 3 The XRD results show the formation of pure monoclinic Fe 2 W 3 o 12 (Peaks without impurity phase and starting material).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com