Recovery and treatment device and treatment process of butyl-octyl alcohol condensation maintenance waste liquid

A technology for recycling and treatment of waste liquid, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, separation/purification of carbonyl compounds, etc. Deal with costs and other issues to achieve major social and environmental benefits, eliminate the source of odor, and reduce the amount of delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

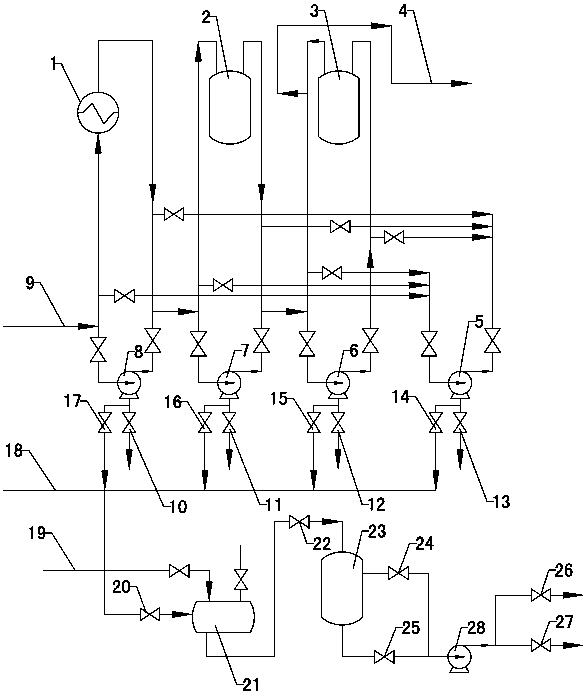

[0025] figure 1 It is the best embodiment of the present invention, below in conjunction with the attached figure 1 The present invention will be further described.

[0026] Refer to attached figure 1 : The recovery treatment device of the butanol condensation maintenance waste liquid, including the first condensation reactor 2, the second condensation reactor 3, two condensation reactors, mechanical seal 1, four circulation pumps, feed pipeline 9 and discharge The condensation reaction loop formed by the pipeline 4, the first condensation reactor 2, the second condensation reactor 3 and the mechanical seal 1 respectively form a set of series loops with a circulation pump, and the three sets of series loops pass through another circulation pump and corresponding The control valves form a parallel circuit, the feed pipeline 9 is fed through the mechanical seal 1 loop, and the discharge pipeline 4 is discharged through the second condensation reactor 3 loop, and a waste liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com