Thermal field structure for drawing zone-melting 8-12-inch silicon single crystal

A silicon single crystal, drawing area technology, applied in the direction of single crystal growth, single crystal growth, self-regional melting method, etc., can solve the problems of generator power increase, ionization breakdown, thermal stress increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

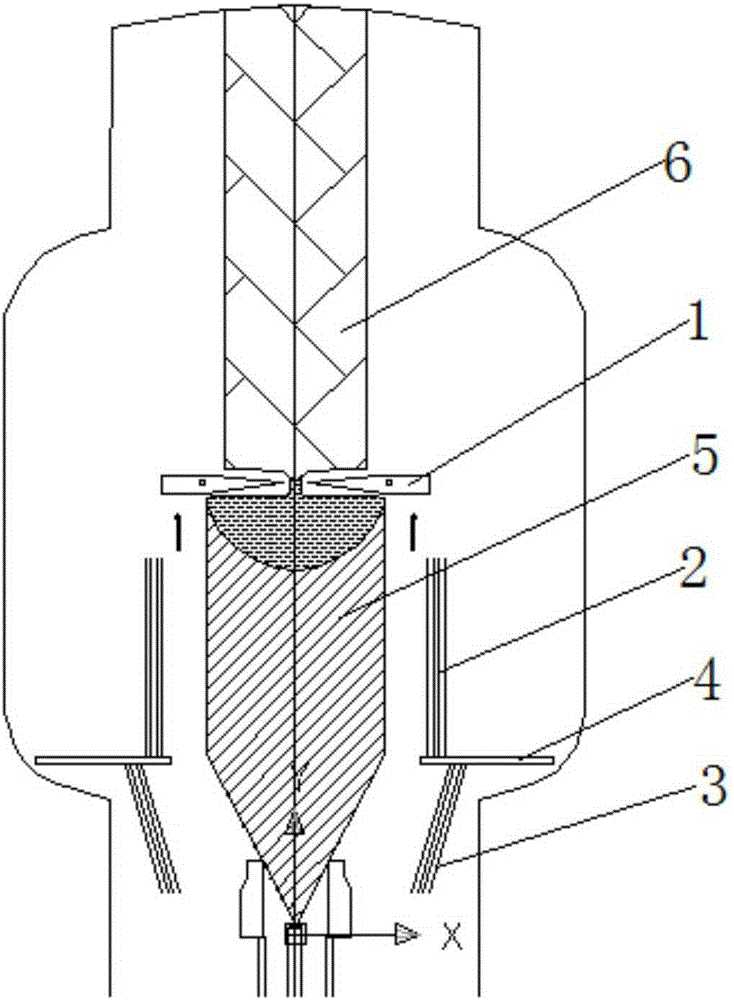

[0028] Such as Figure 1-4 As shown, a heat field structure for melting 8-12 inch silicon single crystal 5 in the drawing zone, including a sharp-angle coil 1, a middle heat shield 2 and a lower heat shield 3;

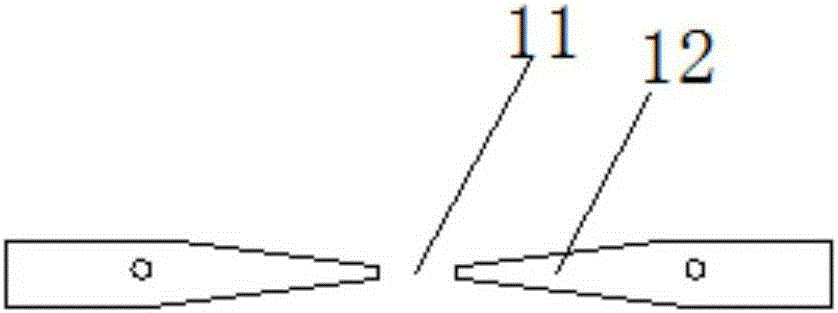

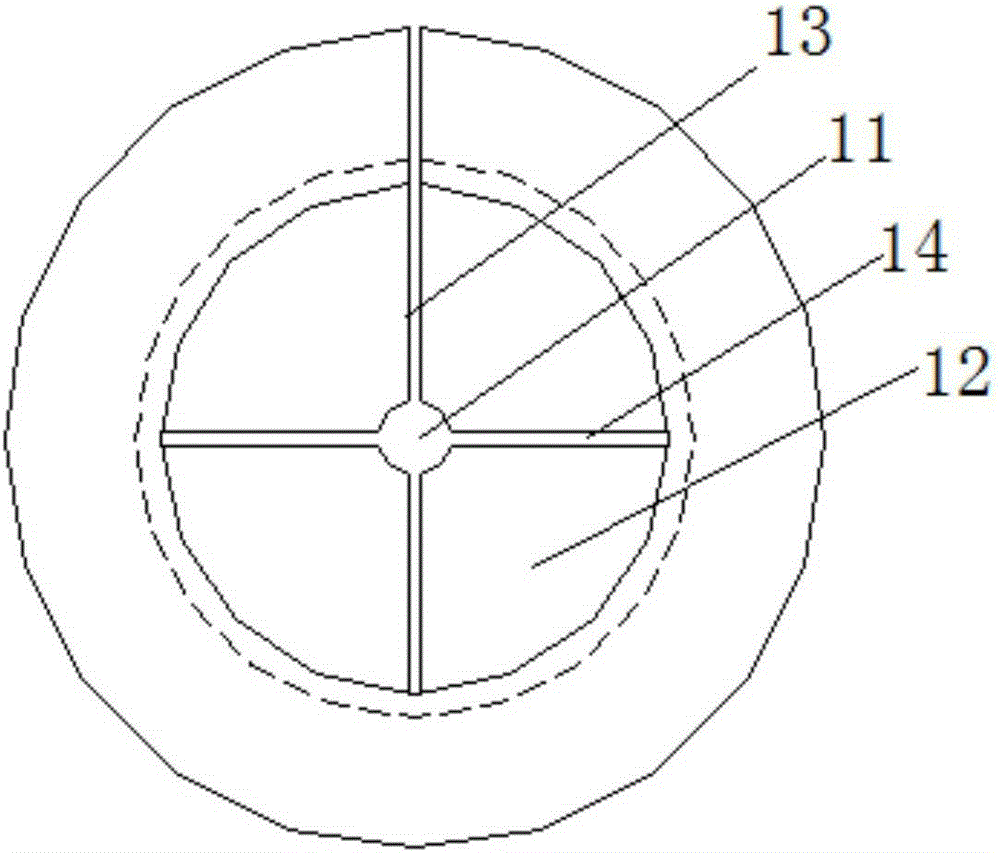

[0029] The pointed coil 1 is located in the melting zone between the polycrystalline rod 6 and the single crystal rod 5 in the furnace, the polycrystalline rod 6 is located in the upper part of the furnace, and the single crystal rod 5 is located in the polycrystalline rod 5 Below the crystal bar material, the pointed coil 1 is a circular coil, the diameter of the circular coil is 160-300mm, and the center of the circular coil is provided with a coil eye 11. Between the edge an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com