A rotary electrospinning device for preparing nanofibers

A technology of electrospinning and nanofibers, applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve problems such as air breakdown, discharge, solution fire and combustion, etc., and achieve the effect of reducing corona discharge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

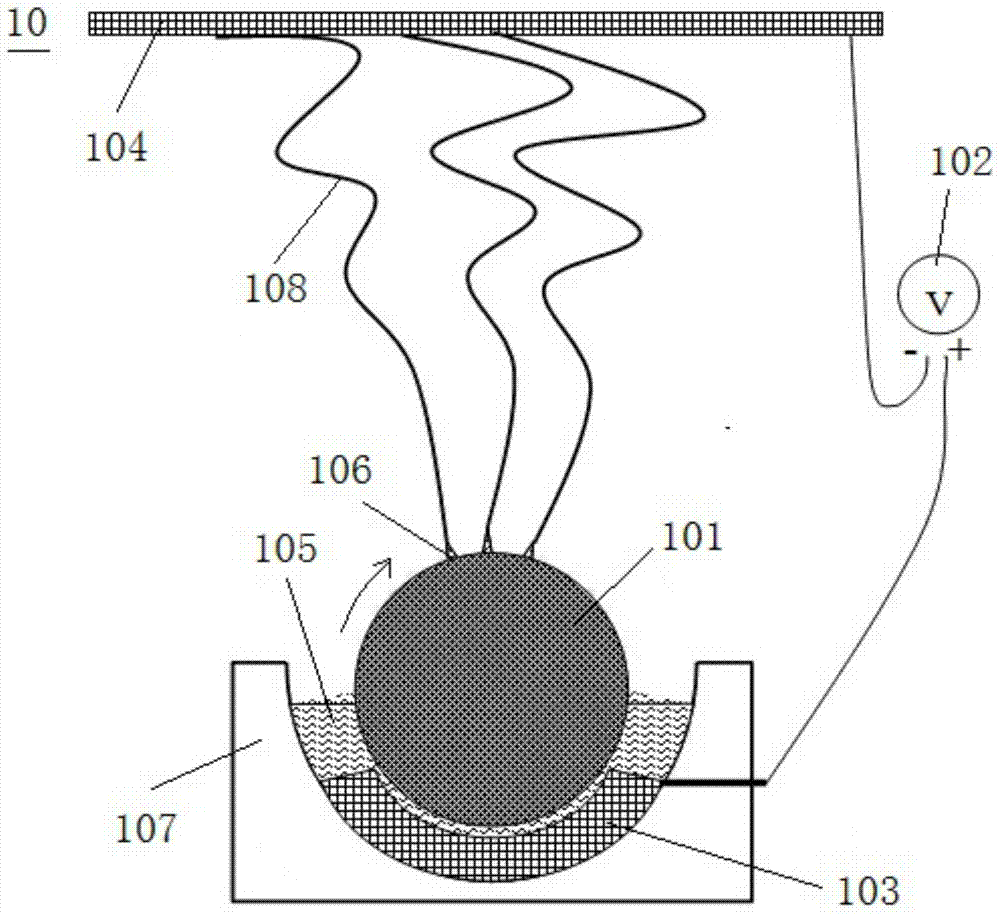

Embodiment 1

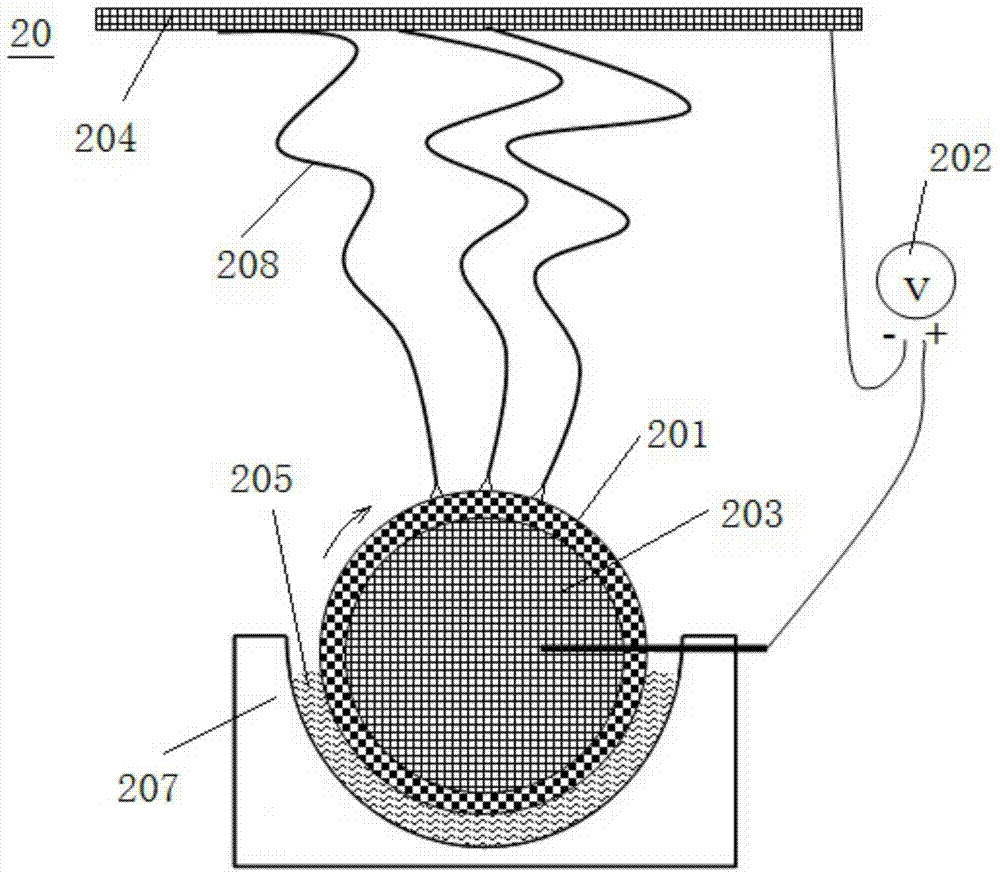

[0025] see figure 2 , a rotary electrospinning device 20 for preparing nanofibers, comprising a high-voltage power supply 202, a polarized electrode 203 connected to the positive and negative poles of the high-voltage power supply 202, and a receiving counter electrode 204, a liquid tank 207, placed in the liquid tank The spinning solution 205 in the spinning solution 205, the rotation generator 201 partially placed in the spinning solution 205, the polarized electrode 203 is located inside the rotation generator 201, and the surface of the rotation generator 201 is a dielectric material , the dielectric constant is not less than 10, preferably not less than 100, more preferably not less than 1000, and the dielectric material is ceramic, or a mixed material of ceramic, metal powder and polymer material. The ceramics include lead zirconate titanate, strontium barium titanate, bismuth zinc niobium. The shape of the rotary generator is circular, with an outer diameter of 70mm, ...

Embodiment 2

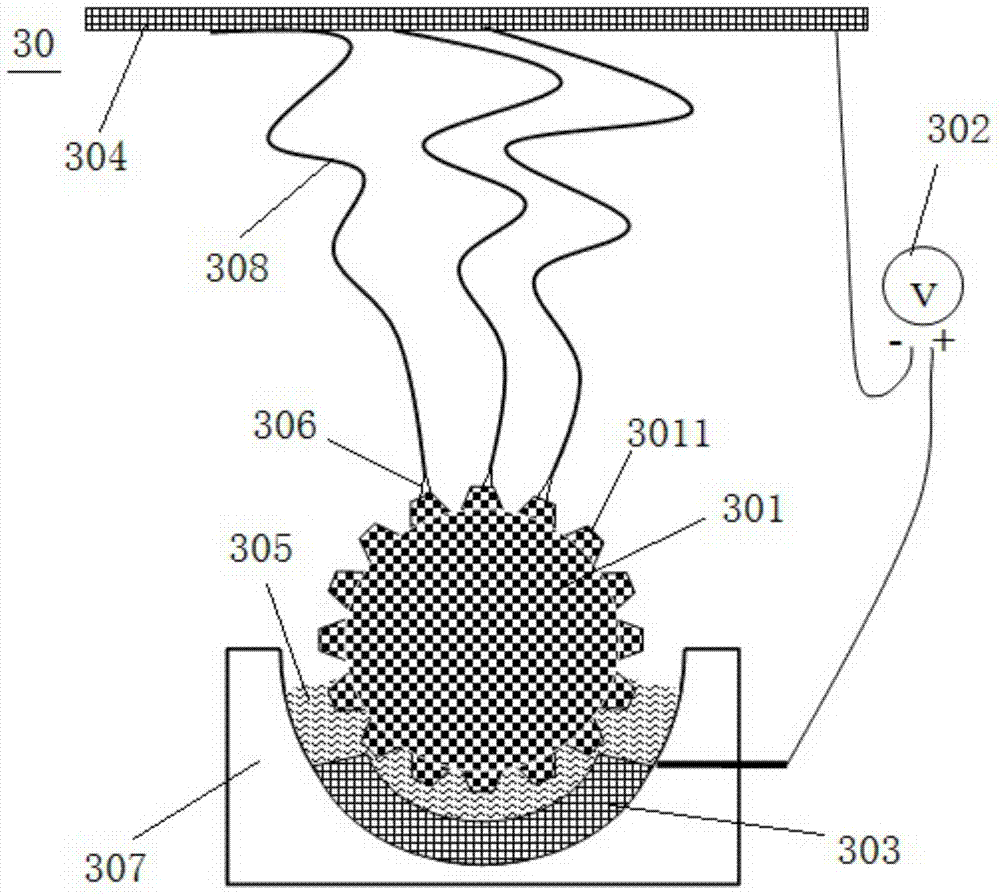

[0027] see image 3 , a rotary electrospinning device 30 for preparing nanofibers, comprising a high-voltage power supply 302, a polarized electrode 303 connected to the positive and negative poles of the high-voltage power supply 302, and a receiving counter electrode 304, a liquid tank 307, placed in the liquid tank The spinning solution 305 inside, the rotation generator 301 partially placed in the spinning solution 305, the polarized electrode 303 is located in the spinning solution 305 outside the rotation generator and is located in the rotation generator Below the generator 301, the polarized electrode 303 is arc-shaped, its inner diameter is close to the outer diameter of the rotary generator 301, and the length of the arc is 5%-40% of the circumference. The electrode material includes: wire, mesh, grid, foam , sponge, cloth, braid, fin, parallel plate, cohesive powder structure, interwoven material, etc., the specific surface area of the polarized electrode is at le...

Embodiment 3

[0029] see Figure 4 , a rotary electrospinning device 40 for preparing nanofibers, comprising a high-voltage power supply 402, a polarized electrode 403 connected to the positive and negative poles of the high-voltage power supply 402, and a receiving counter electrode 404, a liquid tank 407, placed in the liquid tank The spinning solution 405 in the spinning solution 405, the rotation generator 401 partially placed in the spinning solution 405, the polarized electrode 403 is located inside the rotation generator 401, and the rotation generator 401 is a dielectric material. The electrical constant is not less than 10, preferably not less than 100, more preferably not less than 1000, and the dielectric material is ceramics, or a mixed material of ceramics, metal powder and polymer materials. The ceramics include lead zirconate titanate, strontium barium titanate, bismuth zinc niobium. The high voltage power supply is a high voltage direct current power supply. The shape of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com