Resonant type pressure sensor

A pressure sensor and resonant technology, applied in the field of MEMS micro-sensors, can solve the problems of increased sensor complexity, electrostatic attraction of movable parts, and low compensation accuracy, so as to increase process complexity, reduce complexity, and improve measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to solve the problem of temperature measurement deviation in the temperature compensation process of the sensor, the present invention proposes a dual-parameter sensitive resonant pressure sensor for pressure and temperature.

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

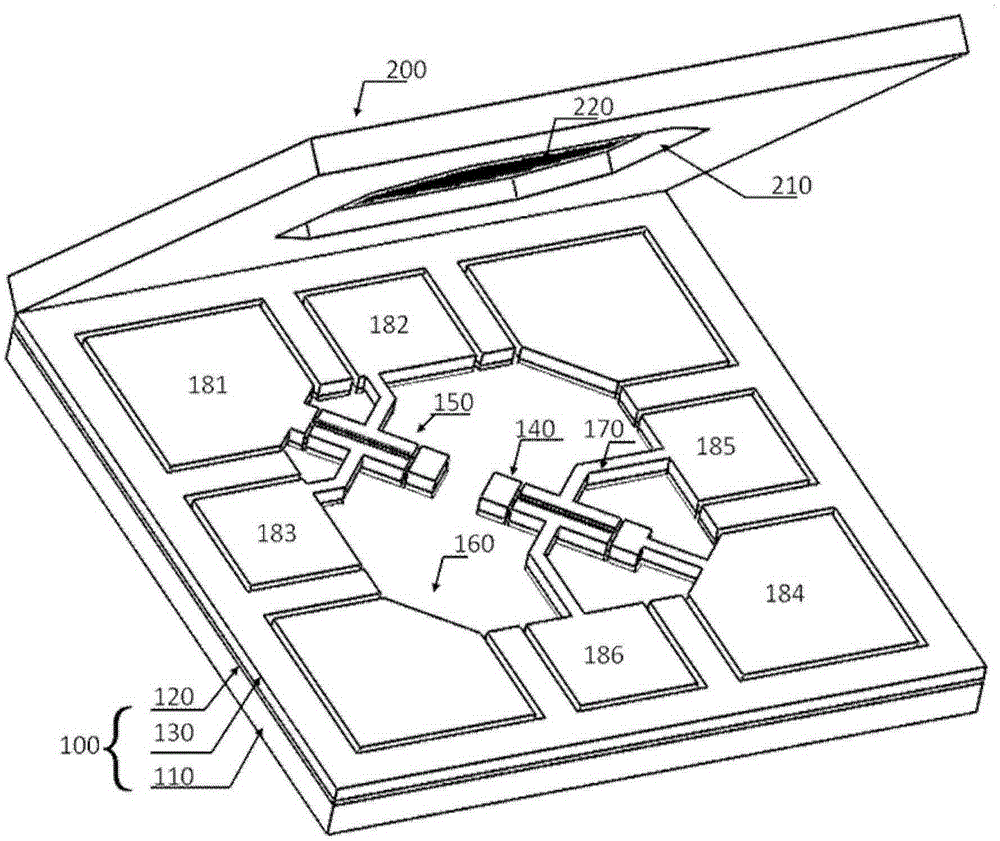

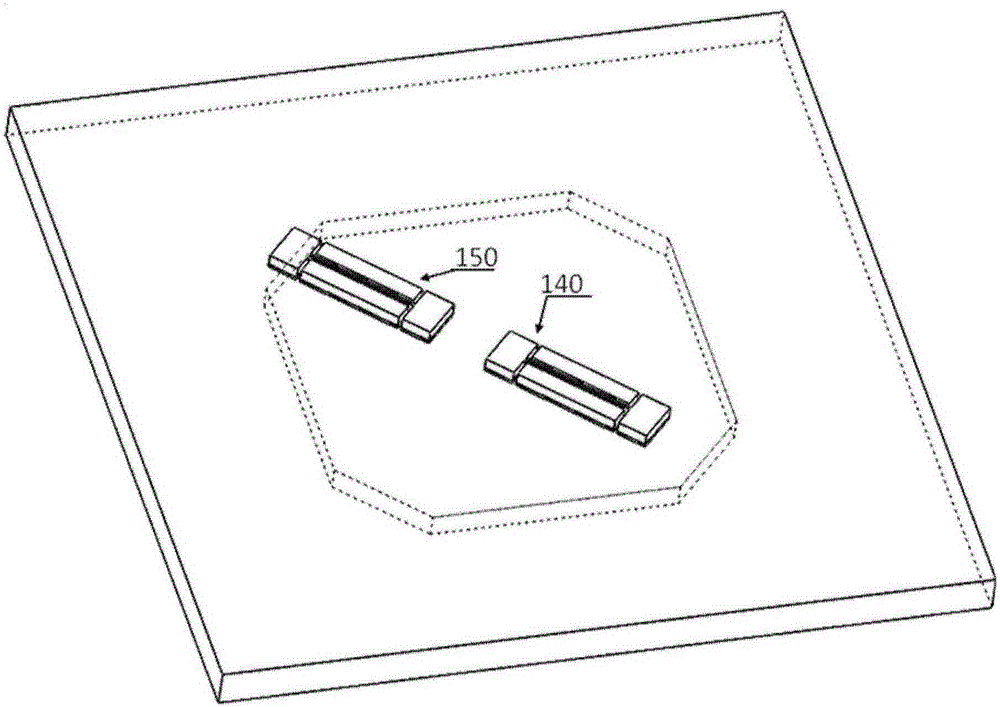

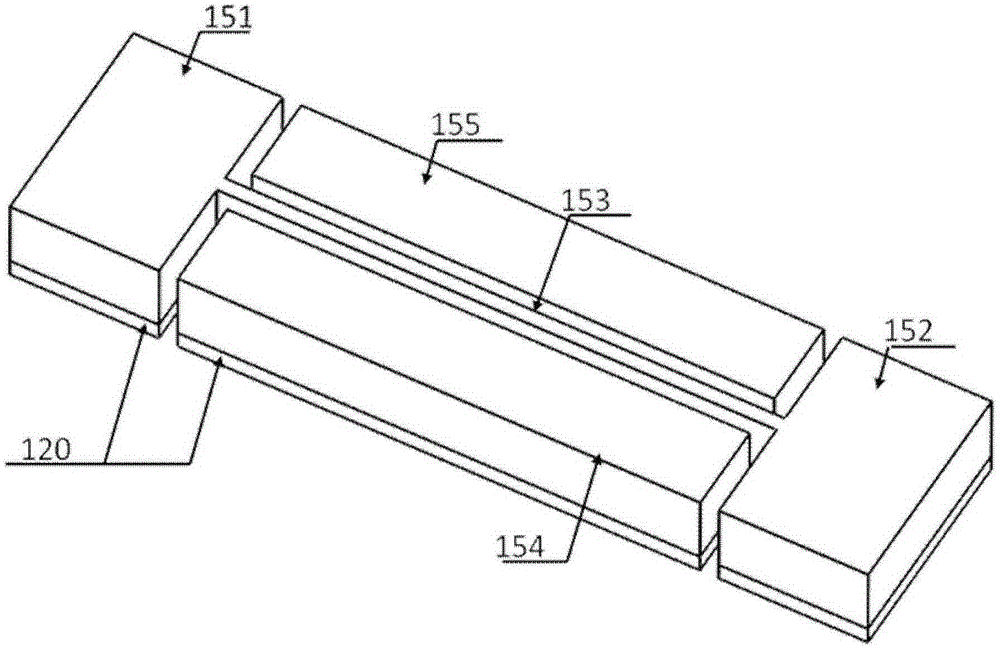

[0036] In an exemplary embodiment of the present invention, a resonant pressure sensor is provided. Please refer to figure 1 , the resonant pressure sensor of this embodiment includes: a sensor body 100, a pressure sensitive film 160 is formed at the bottom thereof, and two resonators with the same natural frequency are formed on the pressure sensitive film 160—the first resonator 140 and the second resonator 150, wherein the first resonator 140 is located at the center of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com