Large tank hanging static testing device

A static test and suspension technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of increased test installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

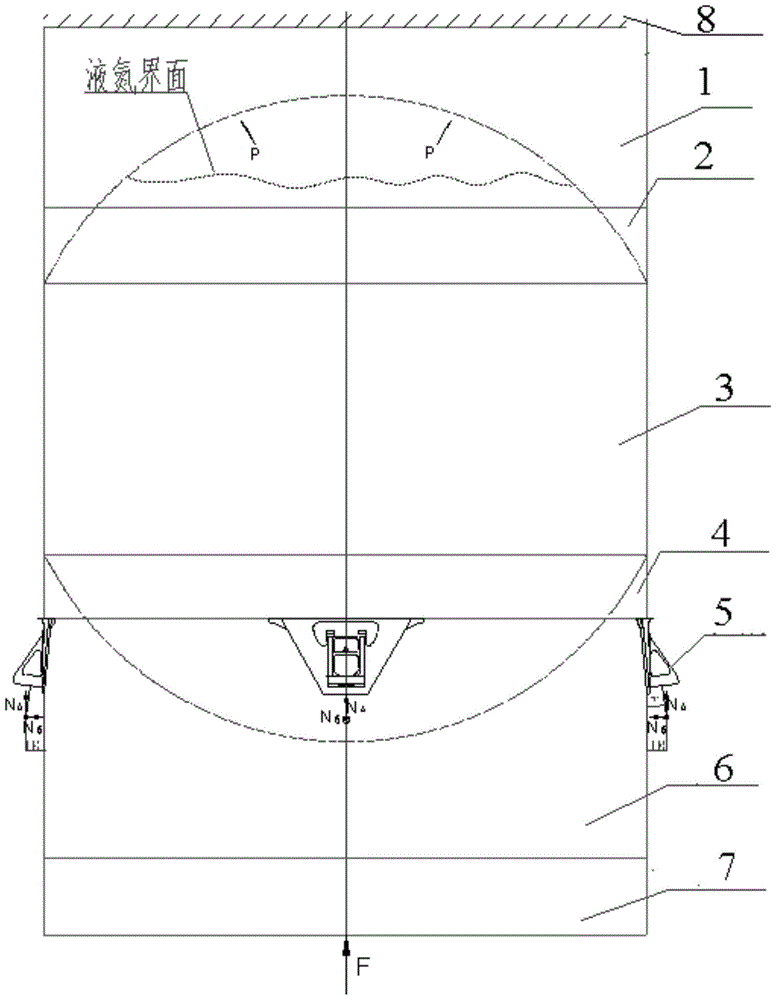

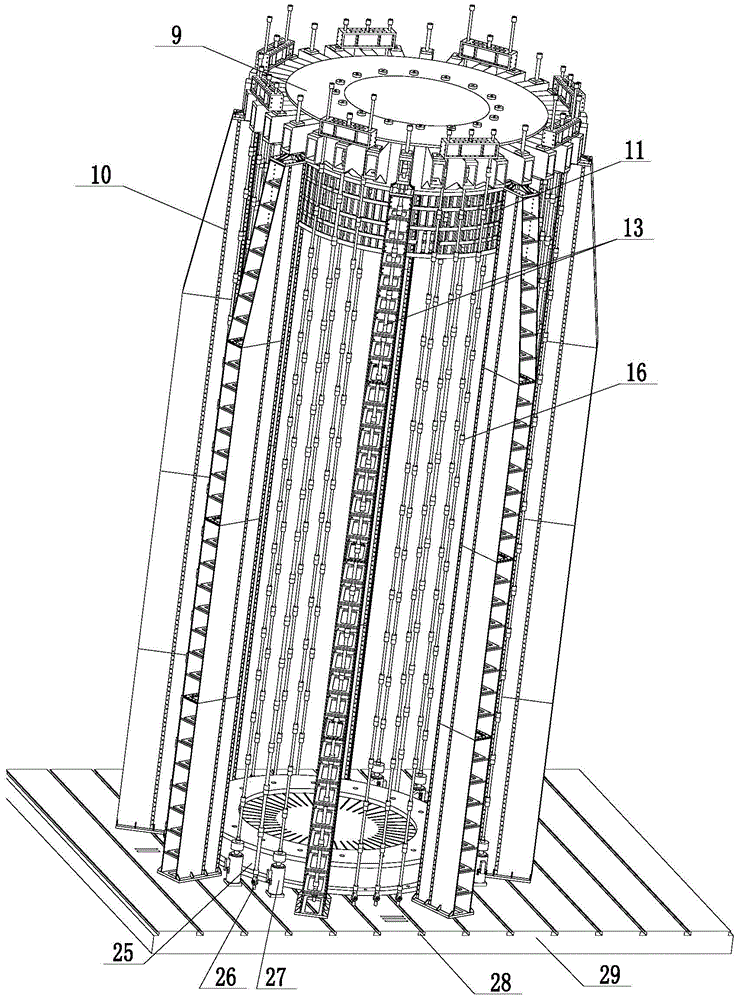

[0021] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as figure 2 As shown, the large-scale storage tank suspension type static test device of the present invention comprises: afterburner cap 9, upright post 10, steel frame 11, pull rod 13, connecting nut 16, test platform 25, ground bearing point 26, force Loading equipment 27, load-bearing ground rail 28, and foundation 29; wherein, the outer diameter of the test platform 25 is 5600 mm, and 32 load-bearing points 26 of 50 tons are evenly distributed around the test platform 25 at a position of 6800 mm. First, 8 groups of 16-meter-high upright columns 10 are evenly distributed in the four quadrants of the test platform 25 . There are 32 cantilevers evenly distributed on the periphery of the afterburner cap 9, and there are through holes with a diameter of Φ74 on each cantilever. The diameter of the distribution circle of thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com