Method for detecting Young's modulus of piezoelectric material surface by laser surface acoustic wave

A surface acoustic wave and piezoelectric material technology, applied in the direction of material analysis, measuring devices, and analysis materials through optical means, can solve problems such as lack of applicability, influence of measurement results, expensive equipment, etc., to make up for inapplicability, Promote theoretical research and practical application, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

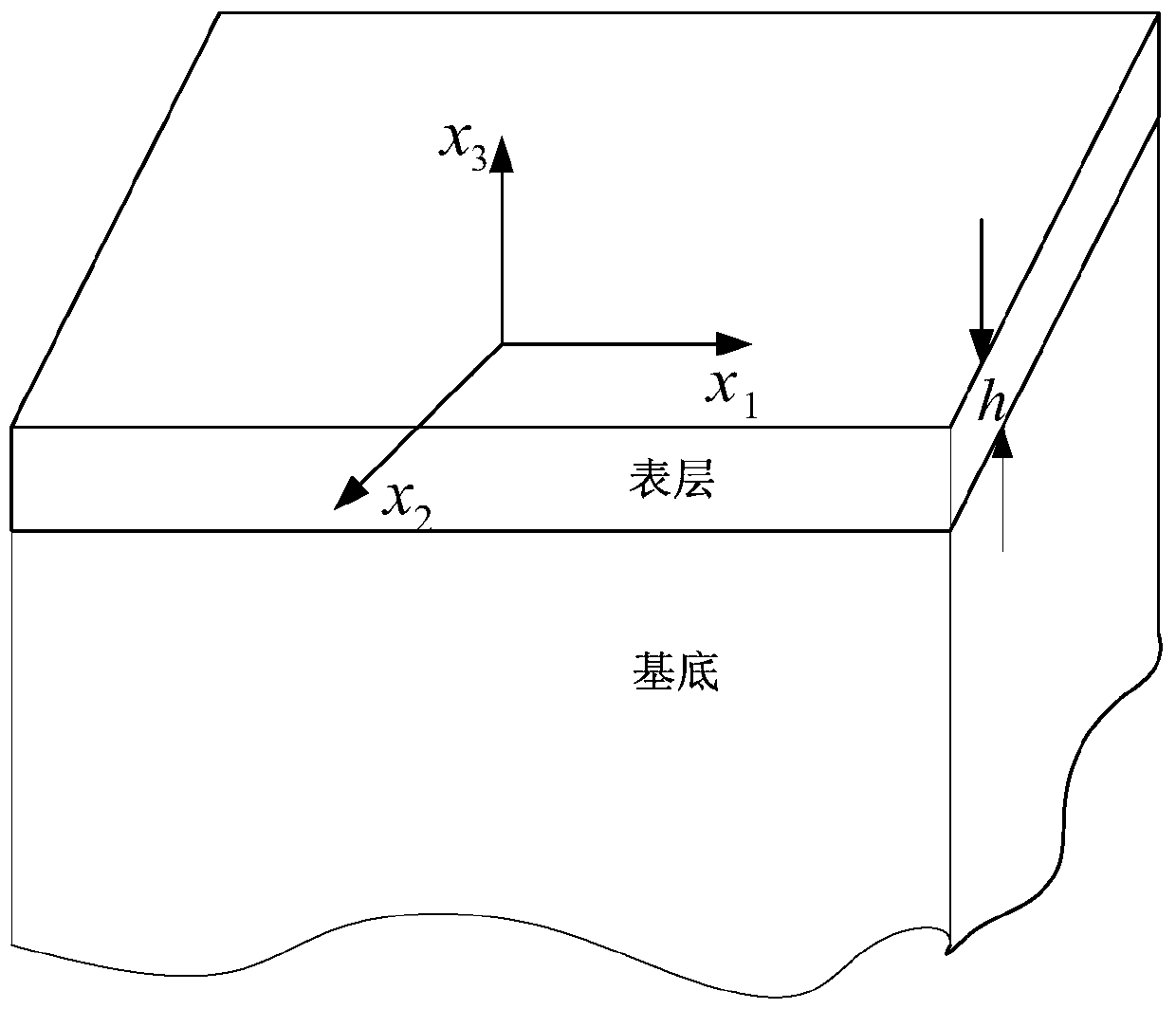

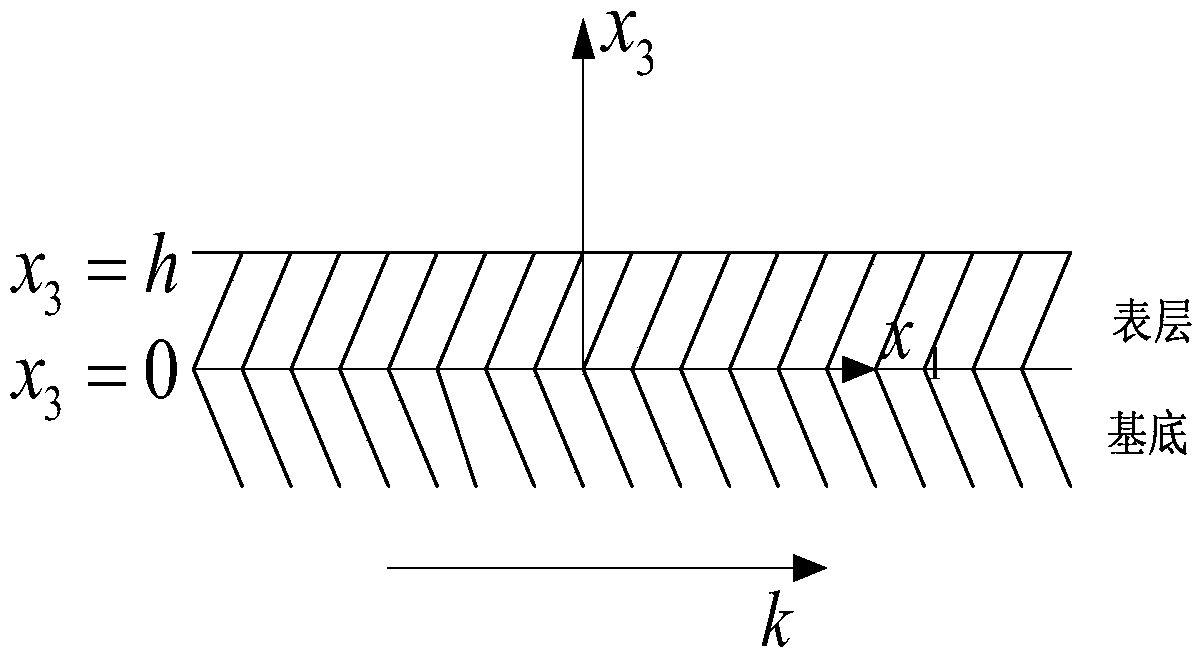

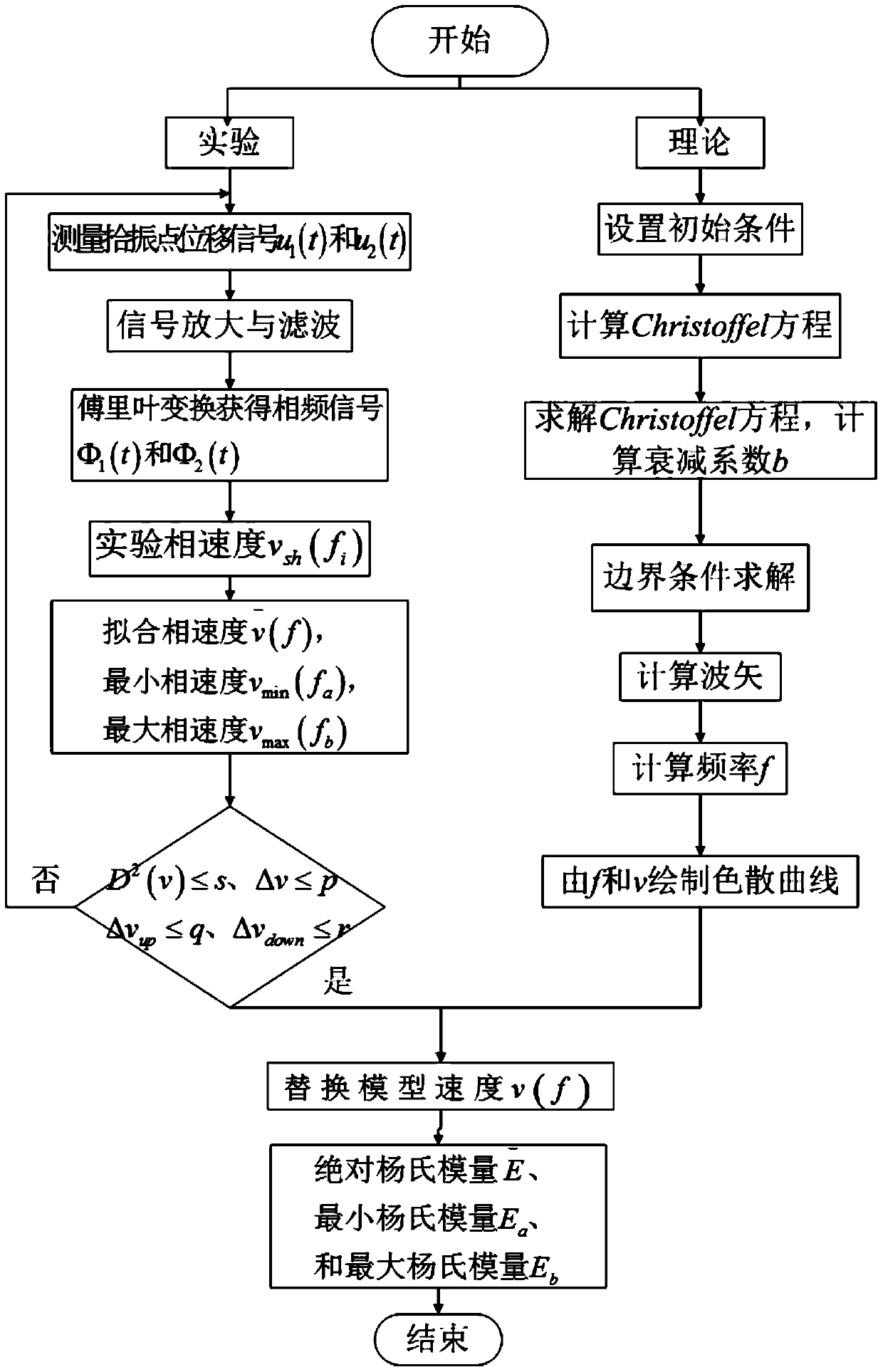

[0043] Such as figure 2 As shown, the design idea of the present invention is to set out from experiment and theory respectively, firstly according to the experimental data u 1 (t) and u 2 (t) Perform Fourier transform to obtain the phase-frequency signal Φ 1 (t) and Φ 2 (t), unwind it to obtain the experimental phase velocity v sh (f i ), to obtain the fitted phase velocity minimum phase velocity v min (f a ) maximum phase velocity v max (f b ); at the same time, according to the characteristics of the piezoelectric material, the wave equation in the piezoelectric medium and the electromagnetic wave equation are combined to obtain the Christoffel equation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com