Recyclable leaching device for leaching experiment

A leaching and sample loading technology, which is applied in the field of recyclable leaching devices, can solve the problems of affecting the ecological landscape, impact evaluation, and inability to carry out repeated cycle tests, and achieve the effect of avoiding local disturbance and uneven water inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings, but the practical application of the patent of the present invention is not limited to the illustrated embodiments.

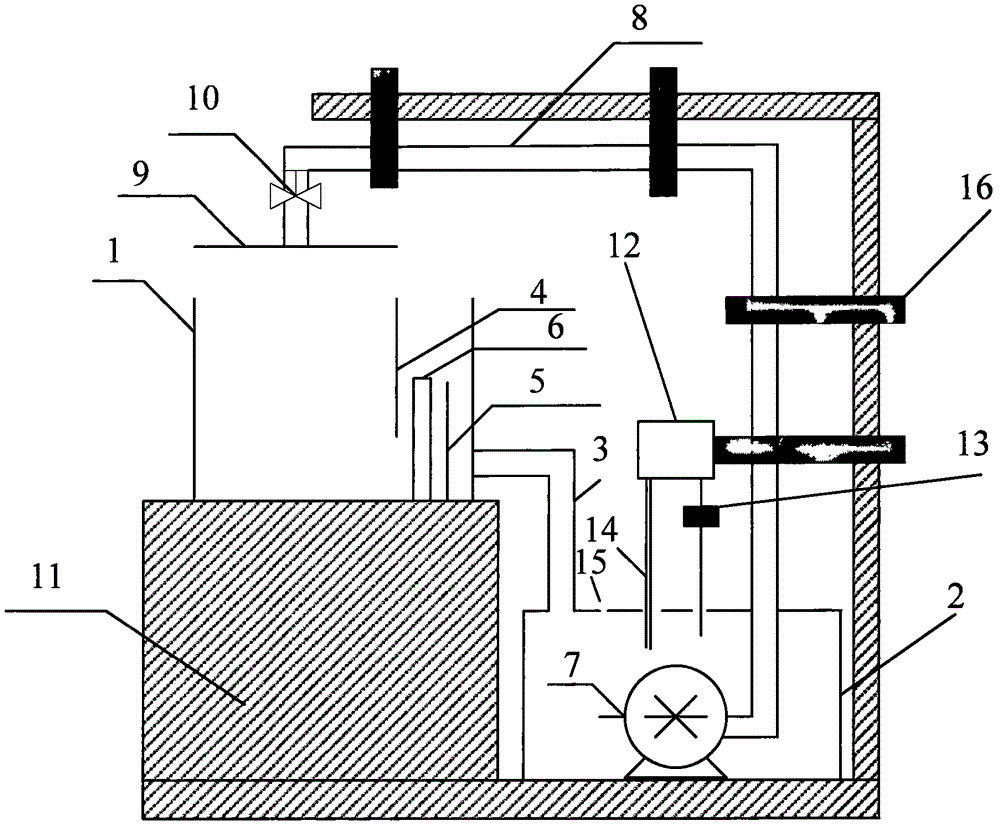

[0023] figure 1 It is a schematic diagram of the principle of a recyclable leaching device for leaching tests in the present invention. The device is composed of a sample loader, a water storage device, a drainage pipe, a submersible pump, a water injection pipe, a sprinkler, a water inlet regulating valve, a filter assembly, a water supply tank, a water level sensor, and a fixed bracket. The sample loader (1) is connected with the water reservoir (2) through a drain pipe (3). Separators (4) and (5) are installed in the sample loader (1). Among them, the partition (4) is sealed and connected with the opposite sides of the sample loader (1), and there is a certain gap with the bottom surface of the sample loader 1; the partition (5) is connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com