Modified TPE material production process and modified TPE material

A production process and modification technology, which is applied in the field of TPE materials, can solve the problems of long time consumption, affecting the production efficiency and production capacity of injection molding workpieces, and complicated and complicated processes, and achieve the effects of good mold release performance, superior physical properties and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

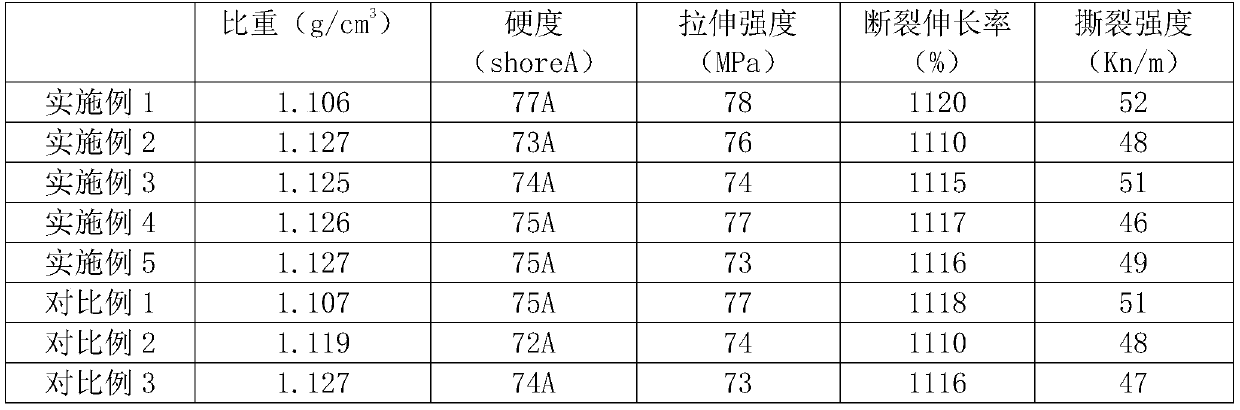

Examples

Embodiment 1

[0049] A modified TPE material production process, comprising the following steps:

[0050] Step 1. Absorption of white oil: put SEBS and white oil into the mixer in turn, and stir for 30 minutes at a stirring speed of 30r / min to mix evenly, so that SEBS can fully absorb the white oil. The white oil in this example is KN4006;

[0051] Step 2, preparation of mixture: put polyurethane and polyurethane grafting agent into the mixer and mix with SEBS that has absorbed white oil, after stirring for 30min, a uniform mixture is obtained;

[0052] Step 3. Twin-screw extrusion molding: Put the mixture into the feed port of the twin-screw extruder, and use a high-speed gear pump to add silicone oil to the liquid filling port of the melt extrusion section. The aforementioned high-speed gear pump uses 3000r / min High-speed gear pump, the material extruded from the outlet of the twin-screw extruder is the modified TPE material;

[0053] Among them, the proportion relationship between the a...

Embodiment 2

[0058] The production process of the modified TPE material in this example is slightly different from that in Example 1. The difference lies in the addition of fillers during the preparation of the mixture in step 2. The ratio between the amount of silicone oil added per unit time and the extruded amount per unit time of the screw extruder is 0.4:100. In addition, the specific selection and dosage of each material are slightly different.

[0059] In the preparation process of this embodiment, the list of materials added is as follows:

[0060] materials Percentage (%) SEBS 20 No. 32 white oil 19 Polyurethane 55 Polyurethane Grafting Agent 1901 3 2000 calcium carbonate 2.6 silicone oil 0.4

Embodiment 3

[0062] The production process of the modified TPE material in this example is slightly different from that in Example 2, and the specific selection and dosage of each material are slightly different. In this embodiment, the ratio between the amount of silicone oil added per unit time and the extruded amount per unit time of the screw extruder is 0.5:100. In this embodiment, the temperature of the silicone oil filling port is 260°C.

[0063] In the preparation process of this embodiment, the list of materials added is as follows:

[0064] materials Percentage (%) SEBS 25 No. 10 white oil 25 Polyurethane 45 Polyurethane Grafting Agent 1901 3 2000 mesh calcium carbonate 0.8 2500 mesh calcium carbonate 0.7 silicone oil 0.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com