Precision reliability analysis method for heavy numerical control machine tool

A heavy-duty CNC machine tool and analysis method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of heavy-duty CNC machine tool accuracy and reliability decline, and achieve scientific and reasonable evaluation of dynamic reliability and maintenance cost high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

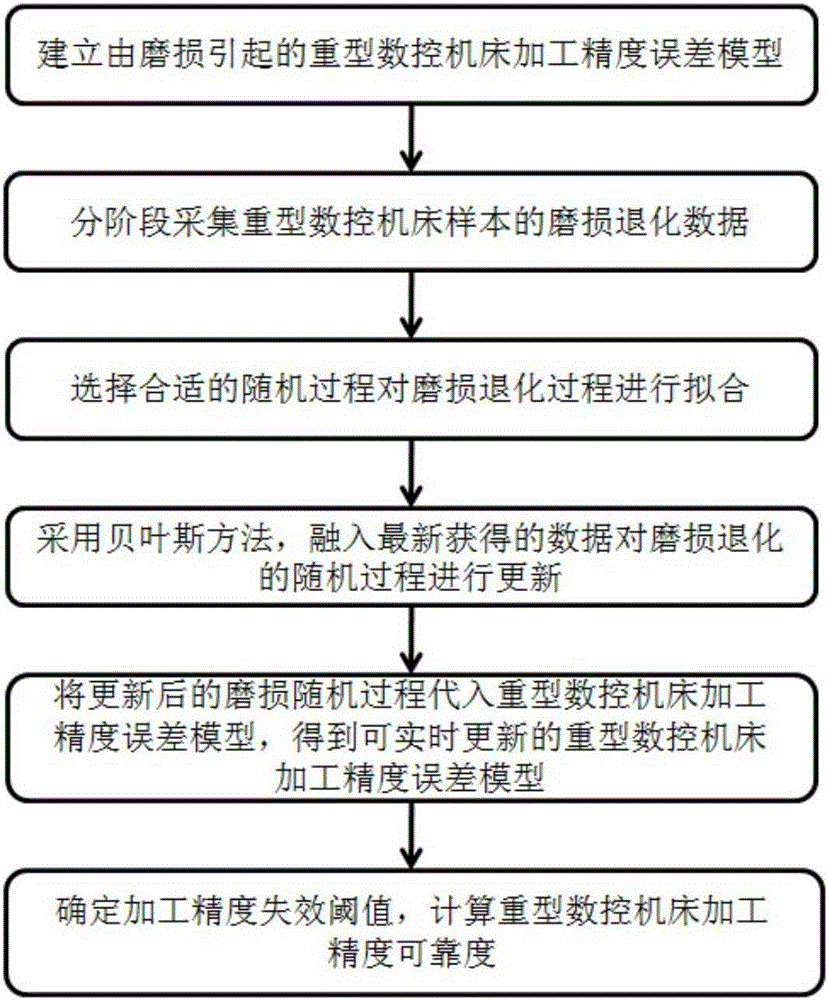

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention is further described: a kind of heavy-duty numerical control machine tool accuracy reliability analysis method based on multi-body system kinematics theory, comprises the following steps:

[0026] Step 1: According to the structural characteristics of the heavy-duty CNC machine tool, and considering the wear of the kinematic pair on the core components, the multi-body system kinematics theory is used to establish the precision error model of the heavy-duty CNC machine tool.

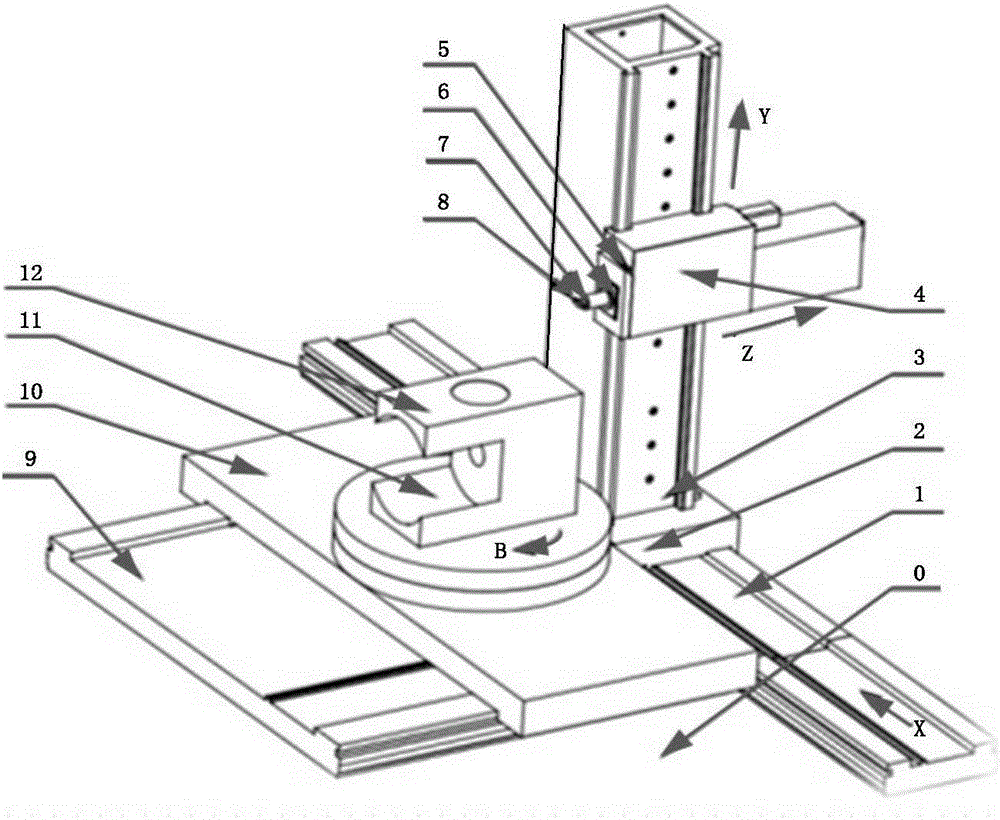

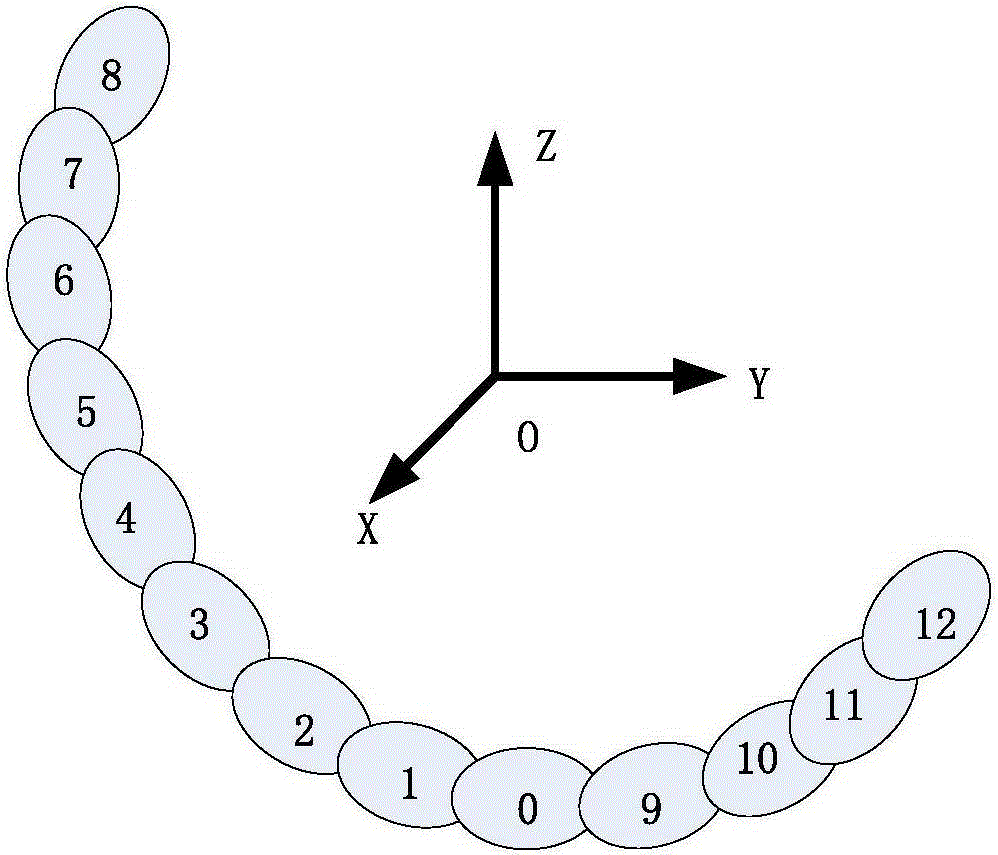

[0027] In this embodiment, the physical model of a certain type of heavy-duty CNC machine tool is as follows figure 2 As shown, the heavy-duty CNC machine tool is mainly composed of foundation 0, bed guide rail 1, slide seat 2, column 3, spindle box 4, square ram 5, milling shaft 6, boring shaft 7, tool 8, workbench 9, and rotary table 10 , workbench 11 and workpiece 12, a total of 12 basic components are formed. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com