Multichannel temperature controller with coupling terminals

A thermostat and terminal technology, which is applied in the field of thermostat technology and equipment, can solve problems such as aggravated self-heating, silver layer damage on the surface of silver contacts, and overheating of the whole machine, so as to improve service life, avoid silver layer damage, and reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

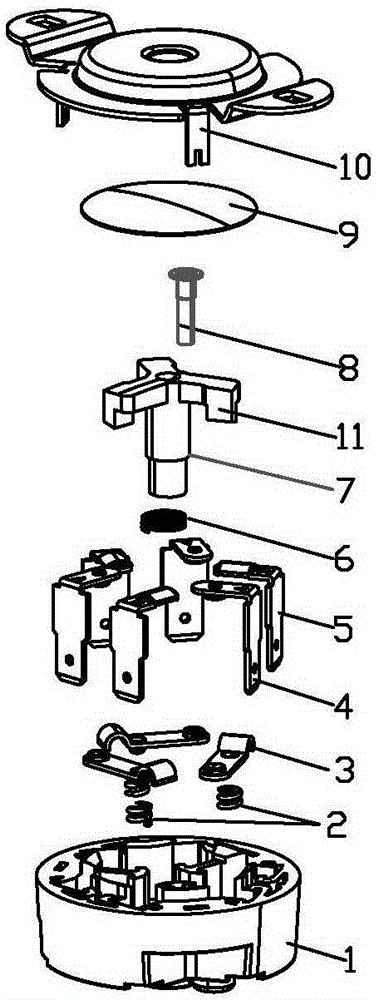

[0021] according to figure 1 , the present invention provides a multi-channel temperature controller with axial terminals, including a housing 1, a small spring 2, a second carrier fluid 3, a first carrier fluid 4, a third carrier fluid 5, a large spring 6, and a large push column 7. Copper thimble 8, bimetal 9, cover 10, push arm 11.

[0022] The housing 1 is a plastic one-piece outer circular structure, and three sets of counterbore holes, three cover pin socket...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap