Noncontact three-dimensional laser foot type measuring system and method

A three-dimensional laser, non-contact technology, applied in the measurement devices of feet or shoe lasts, clothing, applications, etc., to reduce equipment costs, ensure accuracy, and save equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

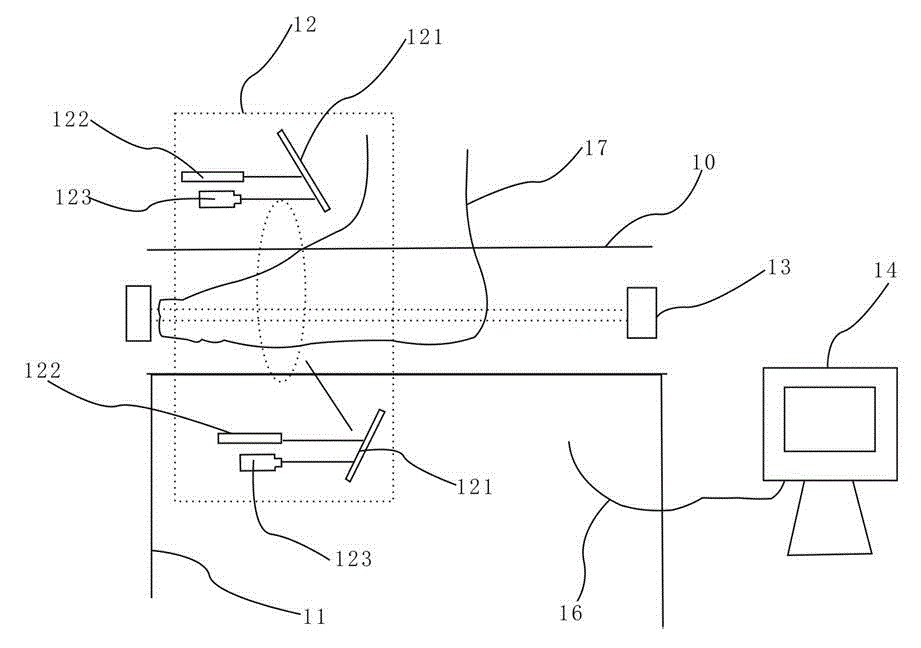

[0067] see Figure 1-2 , the measurement system of non-contact three-dimensional laser foot shape of the present invention, comprises

[0068] The object-carrying glass platform 10 is used to support the placement of the measured foot 17 when measuring the shape of the foot;

[0069] A mechanical support module 11, used to support the object glass platform 10;

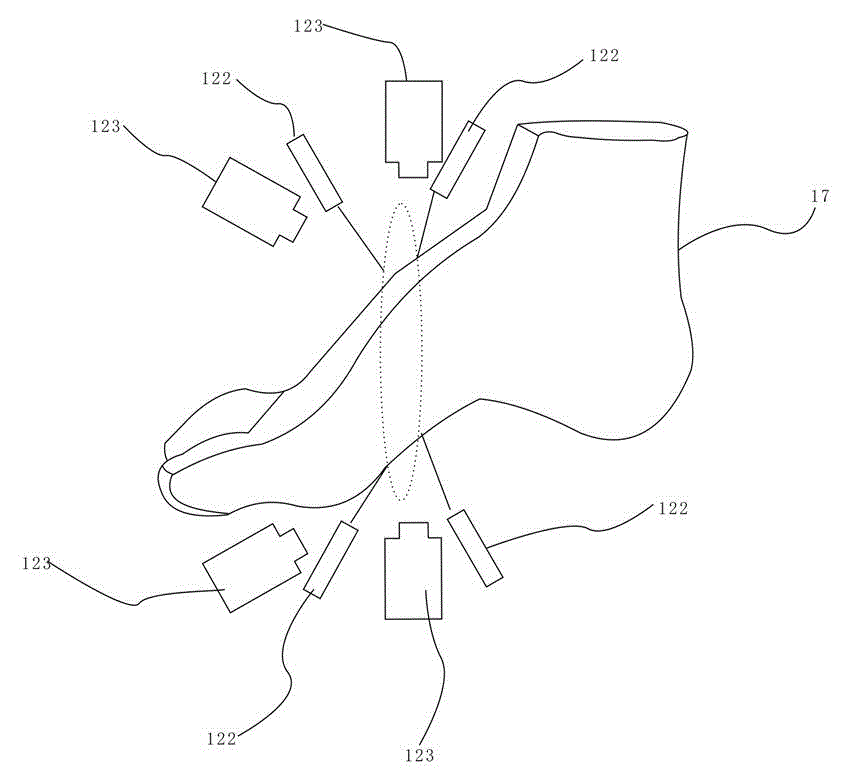

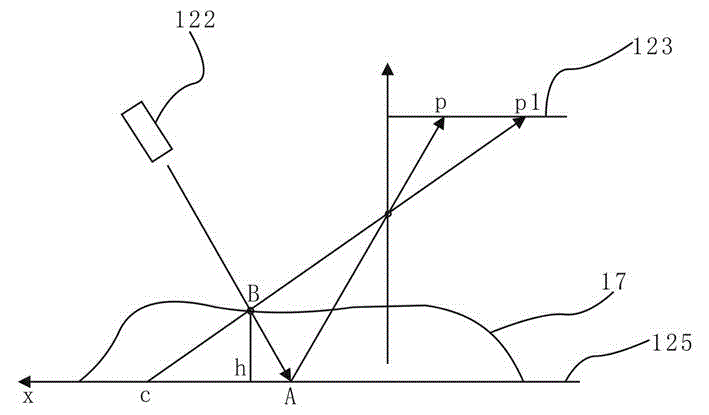

[0070] The optical imaging module 12 projects laser light onto the surface of the measured foot 17, and acquires multi-angle laser images;

[0071] The motion control module 13 drives the motion axis on it to move according to the instruction, the motion control module 13 is connected with the optical imaging module 14, and drives the optical imaging module 12 to perform front and rear measurements;

[0072] The three-dimensional model building module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com