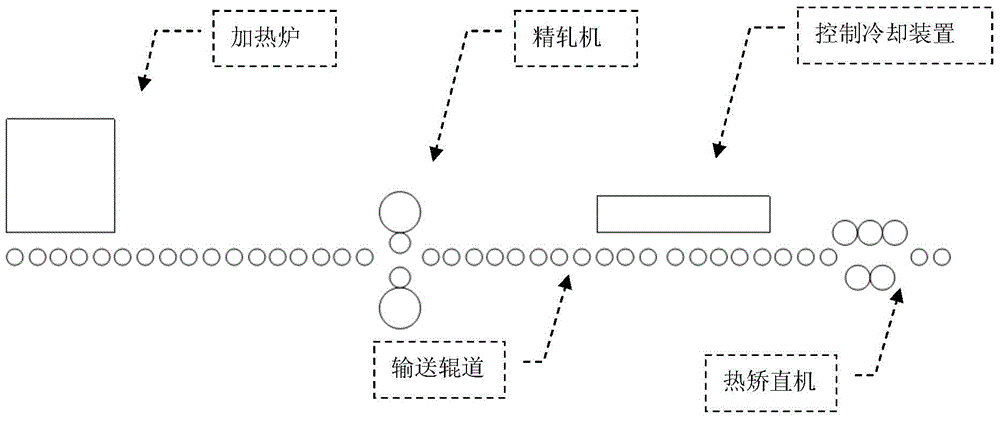

A method for controlling the temperature drop of a steel plate in a medium-heavy plate rolling production line

A control method and temperature drop technology, which is applied in the control of temperature drop in the process, the control of steel plate rolling and conveying speed, and can solve the problems that cannot meet the process requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

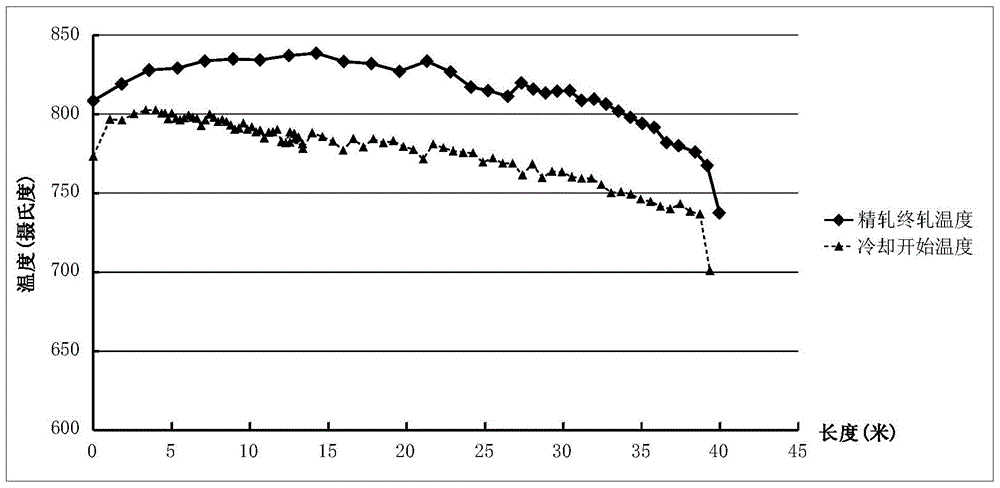

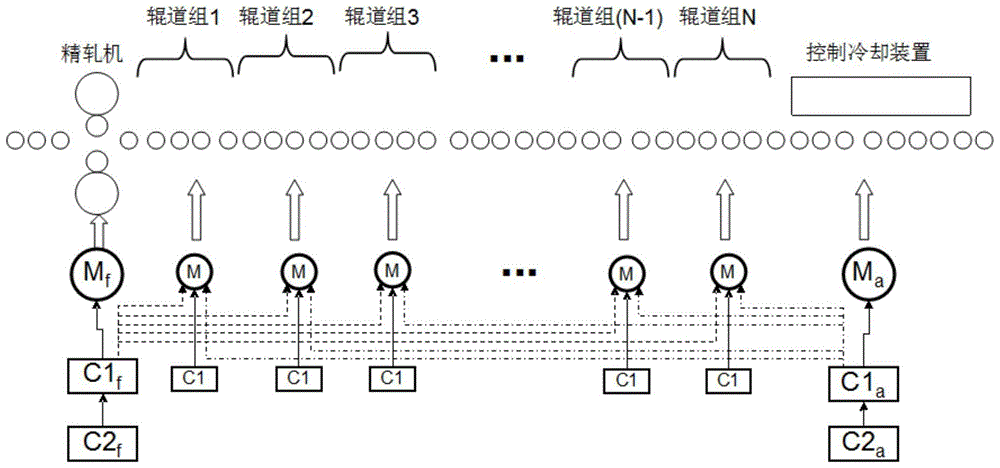

[0178] Assuming that the medium and heavy plate production line is arranged in sequence according to the finishing mill and the controlled cooling device, the roller table group is divided into 6 groups, and the names of each roller table group are FX1, FX2, FX3, FX4, FX5, AC1, and the number between FX5 and AC1. The connected position is the position of the handover point, the distance from the handover point to the finishing mill Sf is 58 meters, and the distance Sa from the handover point to the entrance of the control cooling device is 6.8 meters. The connecting position between FX1 and FX2 is defined as the switching point of the transportation process.

[0179] A new speed control module C2g is added for global coordination to calculate speed map parameters. Change C2f, C1, C1a, C2a, increase communication with C2g and change the original speed control function. Through the above new additions and the reconstruction of the original speed control unit module, a new integ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com