Production and installation methods for moulded concrete embossment decorative plate

A production method and concrete technology, applied in the field of architectural decoration, can solve problems such as construction problems of concrete decorative curtain walls, and achieve the effects of less difficulty in operation and implementation, huge economic benefits, and quick construction results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is applied to a construction project of a certain museum. In this project, the sloping slab of the building's outer eaves is designed with a large area of concrete embossed decorative curtain wall. The construction height is high and the slope is large. The installation height of the first floor reaches 15.7m, and the overall construction area About 5200㎡.

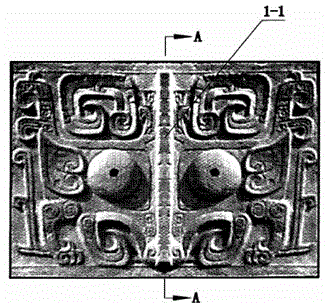

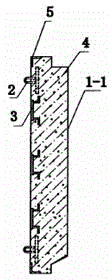

[0031] see Figure 1-Figure 5 , figure 2 Middle 1-1-concrete embossed decorative board 1,1-2 concrete embossed decorative board 2,2-hoisting hook, 3-embedded board, 4-concrete, 5-angle steel frame.

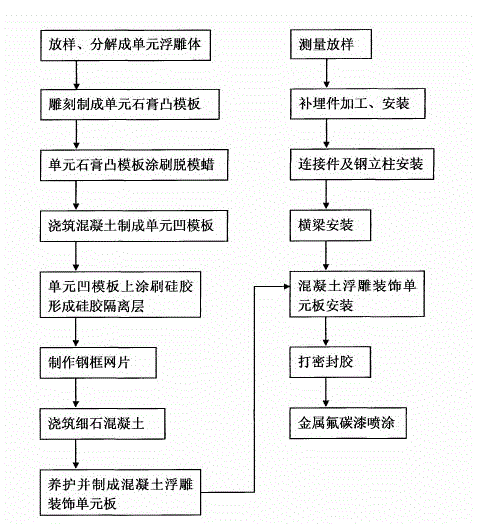

[0032]First of all, the production of molded concrete embossed decorative panels is carried out. According to the design size of the decorative curtain wall, lofting is carried out on the CAD software. Considering the relative integrity of the local embossed pattern and the repeated local patterns in the entire embossed pattern, the size of the divided unit embossed body should not be too large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com