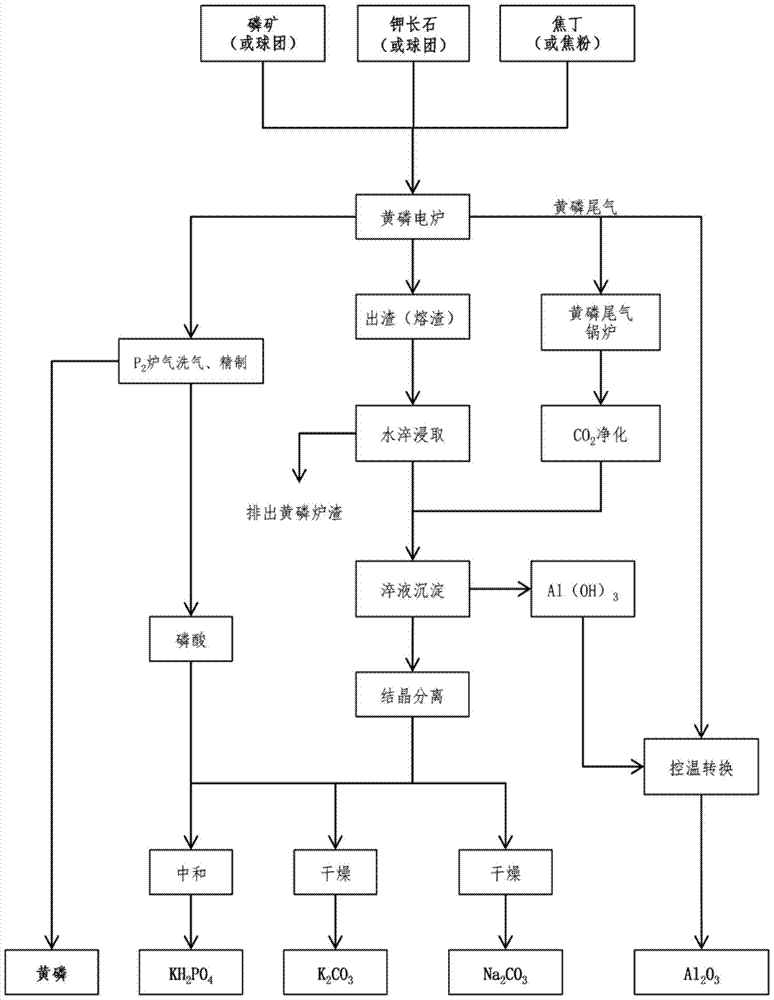

Energy-saving method for co-production of potassium salt, sodium carbonate and alumina from yellow phosphorus

A technology of sodium carbonate and alumina, applied in the chemical industry, can solve problems such as insufficient use of heat, inability to produce high-quality yellow phosphorus, and failure to meet the requirements of yellow phosphorus enterprises, so as to achieve outstanding economic benefits and energy-saving effects, reduce overall production costs, and change Effects of Potassium Depleted Conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] with K 2 O content is 10.5%, Na 2 O content of 2.5% potassium feldspar particles (3 ~ 25mm), and P 2 o 5 content of 29%, SiO 2 content of 13%, CaO content of 41%, CO 2 Phosphate ore (3-25mm) with a content of 8% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of phosphate rock: coke: potassium feldspar = 1000:194:250.

[0058] According to the method of the present invention, 10kt / a yellow phosphorus production plant can produce yellow phosphorus 10kt annually, K 2 CO 3 2.9 kt, Na 2 CO 3 0.53kt, Al 2 o 3 2.65kt. Among them, the production of K 2 CO 3 Capable of deep processing to generate 5.7kt of KH 2 PO 4 .

Embodiment 2

[0060] with K 2 O content is 13%, Na 2 O content of 1.0% potassium feldspar particles (3 ~ 25mm), and P 2 o 5 Content is 30%, SiO 2 content of 11%, CaO content of 42%, CO 2 Phosphate rock (3-25mm) with a content of 10% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of phosphorite: coke: potassium feldspar = 1000:206:278.

[0061] According to the method of the present invention, 20kt / a yellow phosphorus production plant can produce yellow phosphorus 20kt annually, K 2 CO 3 7.3kt, Na 2 CO 3 0.43kt, Al 2 o 3 5.8kt. Among them, the production of K 2 CO 3 Capable of deep processing to generate 14kt of KH 2 PO 4 .

Embodiment 3

[0063] with K 2 O content is 14%, Na 2 Potassium feldspar powder with a small amount of O content, and P 2 o 5 Content is 30%, SiO 2 content of 11%, CaO content of 42%, CO 2 Phosphate concentrate pellets (15-25mm) with a content of 2.5%, and coke (3-25mm) with a fixed carbon content of 80%, add yellow phosphorus according to the ratio of phosphate rock: coke: potassium feldspar = 1000:179:288 electric stove.

[0064] According to the method of the present invention, the 8kt / a yellow phosphorus production device can realize the annual production of yellow phosphorus 8kt, K 2 CO 3 3.14kt, Al 2 o 3 2.3kt. Among them, the production of K 2 CO 3 Capable of deep processing to generate 6.2kt of KH 2 PO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com