Soft plate type photobioreactor

A technology of photobioreactor and reactor, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. It can solve the problems of easy breakage and difference in the flow rate of culture medium, etc. To achieve the effect of optimizing the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Spirulina was cultivated outdoors under natural light. The constructed culture system comprises a soft plate photobioreactor 18, a culture solution storage device 16, a culture solution delivery device 17 (commercially available diaphragm pump), a gas-liquid exchange device 19 and CO 2 Supplementary device 20, connected as Image 6 shown.

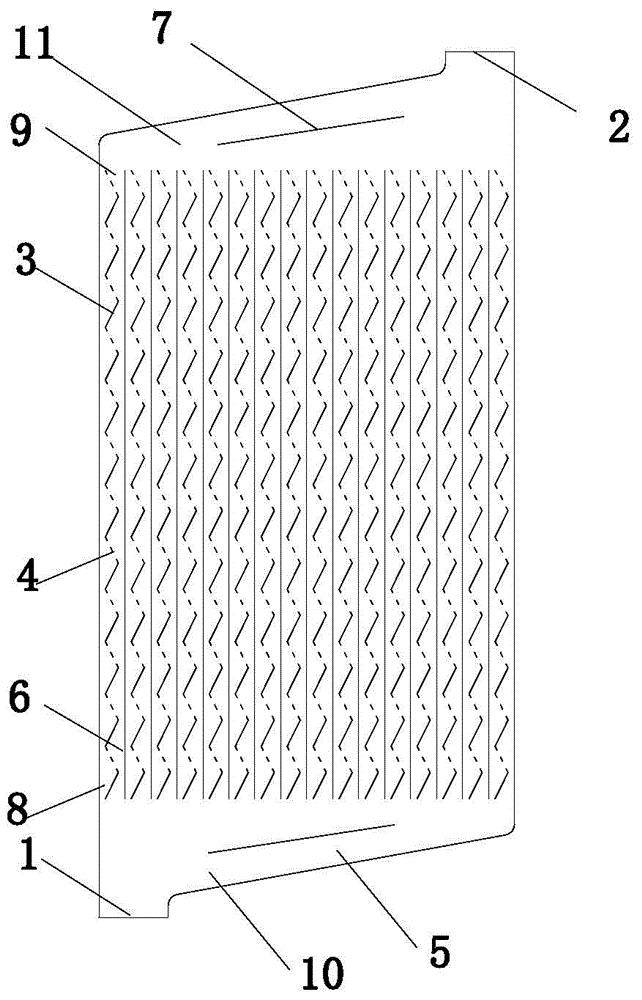

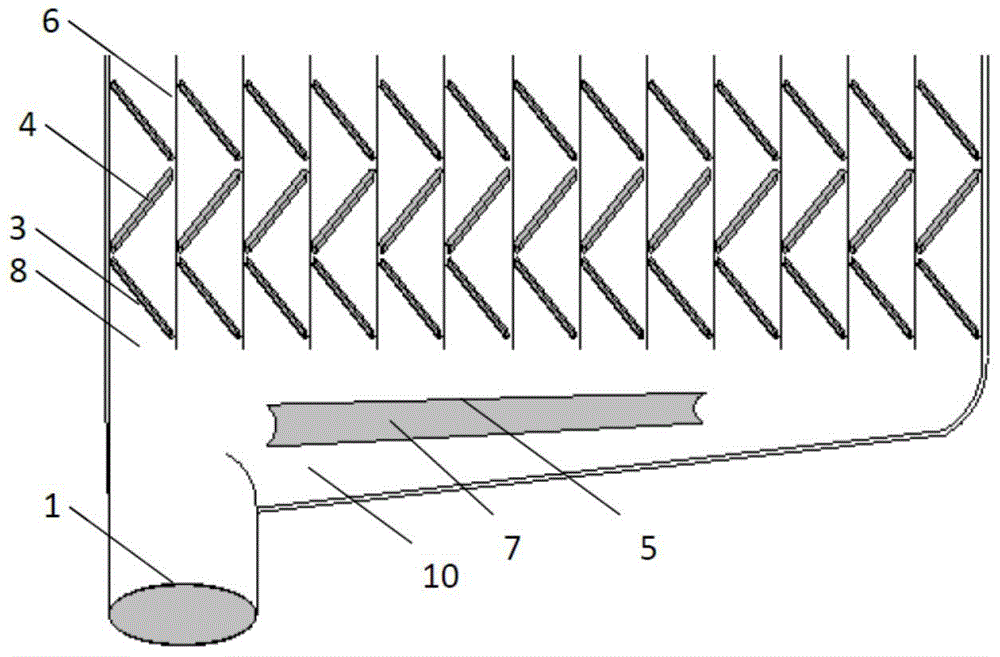

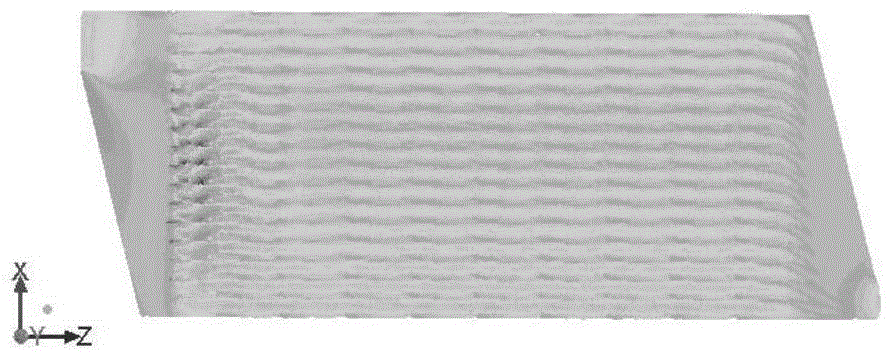

[0069] The structure of the soft plate photobioreactor 18 is as follows: figure 1shown. The soft plate photobioreactor is laid flat on the ground, and the main material is soft light-transmitting polyethylene film. The soft plate photobioreactor is 200cm long and 96cm wide, and is divided into 16 parallel flow channels; the thickness of the main film 5 is 0.5mm, the thickness of the film at 6 ribs is 0.75mm, and the length of the rib 6 is 140cm; The cross-sectional area ratio of the largest and smallest parts of the liquid inlet port 10 and the reactor culture solution outlet port 11 is 2:1; the upper baffle 3 and the lower baff...

Embodiment 2

[0078] The cultivation of spirulina was carried out under natural light outdoors, and the other conditions were the same as in Example 1, except that the thickness of the 6 parts of the ribs of the photobioreactor was twice that of other parts.

[0079] The cultivation process lasted for 60 days, the photobioreactor still operated normally, and the area yield of Spirulina was about 39g / m 2 .d, the service life of the photobioreactor is much higher than that of the photobioreactor in Comparative Example 1; the area yield is higher than that in the photobioreactor in Comparative Example 1. The service life of the photobioreactor of the invention and the utilization rate of light energy when used for cultivating microalgae are obviously improved.

Embodiment 3

[0081] Carry out the cultivation of spirulina under outdoor natural light, other conditions are the same as embodiment 1, difference is that in the photobioreactor, reactor culture solution inlet mouth 10 and reactor culture solution outlet mouth 11 maximum and minimum sectional areas The ratio is 4:1.

[0082] The cultivation process lasted for 30 days, the photobioreactor still operated normally, and the area yield of Spirulina was about 37g / m 2 .d, the service life of the photobioreactor is much higher than that of the photobioreactor in Comparative Example 1; the area yield is higher than that in the photobioreactor in Comparative Example 1. The service life of the photobioreactor of the invention and the utilization rate of light energy when used for cultivating microalgae are obviously improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com