Method for preparing methane-oxidizing bacteria on large scale

A technology for methane-oxidizing bacteria and large-scale preparation, applied in the direction of bacteria, etc., can solve the problems of increasing gas velocity and stirring rate, low solubility, slow growth rate of methane-oxidizing bacteria, etc., and achieves the effect of preventing waste and stabilizing the reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

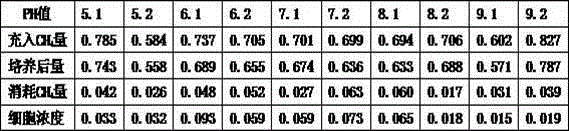

Image

Examples

Embodiment

[0014] A method for preparing methane-oxidizing bacteria on a large scale in this embodiment, the following steps are performed:

[0015] 1) Add methane gas, oxygen, methanotrophs and inorganic salt medium to the reactor;

[0016] 2) Use the crushing device in the reactor to break the added gas into tiny bubbles, so as to blend into the liquid in the reactor and flow along with the liquid along the inside of the reactor to carry out the fermentation process;

[0017] 3) When the mass concentration of the fermentation broth at the outlet of the reactor reaches 2-3%, it is determined that the fermentation process is over, and the product in the reactor is initially concentrated to make the product mass concentration reach 20-30%, and after heating and Rapid cooling and drying are preliminary products.

[0018] The inorganic salt medium in this embodiment includes ammonium chloride, water, sodium pyruvate, KH2PO4, and heptahydrate MgSO4.

[0019] The inorganic salt of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com