Composite heat-insulation and sound-insulation plate

A technology of composite thermal insulation and sound insulation panels, applied in thermal insulation, sound insulation, building components, etc., can solve problems such as unsuitable for application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

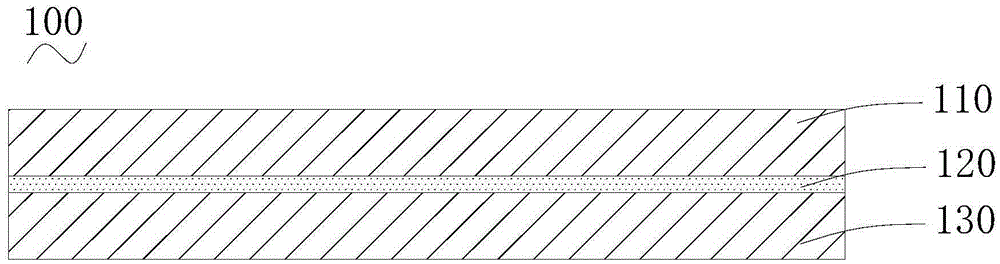

[0051] The composite thermal insulation board 100 of this embodiment is such as figure 2 As shown, it includes a first layer 110, a polyurea aerogel layer 120, and a second layer 130 stacked in sequence. The above three layers are bonded together in sequence. The first layer 110 and the second layer 130 are both paper-faced gypsum layers. The thicknesses of the first layer 110, the polyurea aerogel layer 120, and the second layer 130 are 12 mm, 5 mm, and 12 mm, respectively. The density of the polyurea aerogel layer 120 is 15kg / cm 3 . The size of the composite heat insulation and sound insulation board 100 of this embodiment is 1.2 m×2.4 m.

Embodiment 2

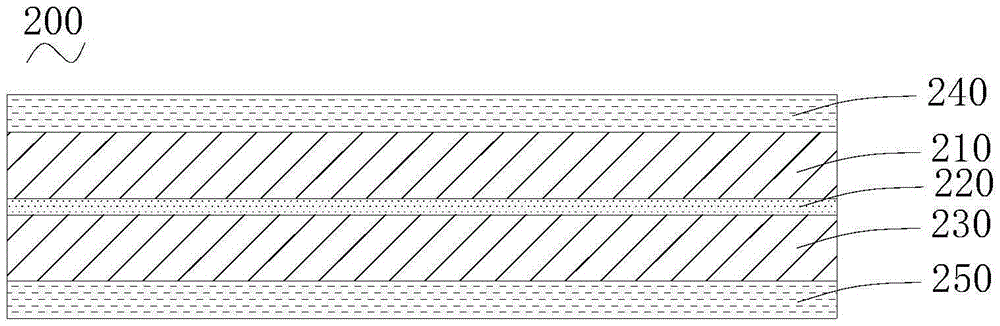

[0053] The composite heat insulation and sound insulation board 200 of this embodiment is such as image 3 As shown, in addition to the first layer 210, the polyurea aerogel layer 220, and the second layer 230 stacked in sequence, it also includes a first fireproof layer 240 located outside the first layer 210 and a second layer 230 outside. The second fire protection layer 250. The above five layers are glued together in sequence. The first layer 210 and the second layer 230 are both paper-faced gypsum layers. The thickness of the first layer 210, the polyurea aerogel layer 220, and the second layer 230 are 12 mm, 2 mm, and 12 mm, respectively. The thickness of the first fireproof layer 240 and the second fireproof layer 250 are both 5 mm. The density of the polyurea aerogel layer 220 is 15kg / cm 3 . The size of the composite heat insulation and sound insulation board 200 of this embodiment is 1.2m×2.4m.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 2 is that the composite heat and sound insulation board does not include a second fireproof layer. When used as a building board and implemented specifically, the first fireproof layer is placed on the side far away from the wall, and the second layer is placed on the side close to the wall and in contact with the surface of the wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com