High-temperature resisting combined valve connecting device

A connecting device and combined technology, which is applied in the direction of valve devices, lift valves, engine components, etc., can solve the problems of excessive waste of valve parts, high temperature and easy damage, etc., and achieve the effects of prolonging service life, reducing use cost, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

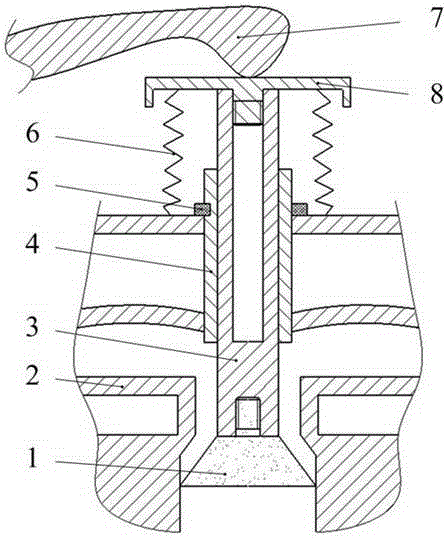

[0015] Such as figure 1 As shown, a high temperature resistant combined valve connection device of the present invention mainly includes a valve head 1, a valve stem 3, a spring seat 8, a spring 6, a valve sleeve 4 and a snap ring 5, and the valve stem 3 is provided with a valve head 1 , the upper end of the valve stem 3 is equipped with a spring seat 8, and the lower end of the spring seat 8 is equipped with a spring 6 and is connected with the valve seat 2. fixed.

[0016] The valve head 1 is made of ceramic material, has a frustoconical structure and a cylindrical head with an external thread on the top, and the cylindrical head of the valve head 1 is installed in the lower blind hole of the valve stem 3 . When working, this design realizes the high temperature resistance of the valve and the replaceability of the valve head 1, that is, the use of the high temperature resistance, heat insulation, high hardness and wear resistance of ceramic materials can reduce the high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com