High-safety fuel rod and manufacturing method thereof

A technology with high safety and manufacturing methods, which is applied in the field of nuclear power, can solve the problems of soft matrix, broken fuel particles, and bending of integrated fuel rods, so as to reduce the possibility of broken, reduce the release of hydrogen, and slow down corrosion The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

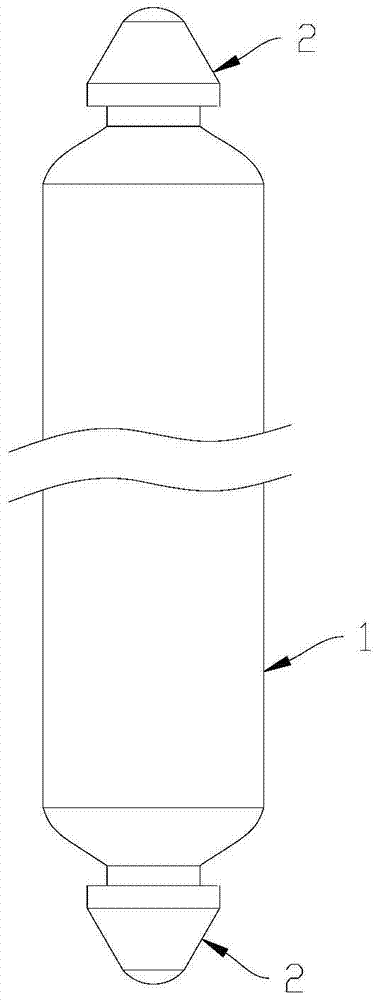

[0036] Such as figure 1 and figure 2 As shown, the high-safety fuel rod in a preferred embodiment of the present invention includes a rod body 1 and two end plugs 2 arranged at the longitudinal ends of the rod body 1, the end plugs 2 are fixedly connected with the rod body 1, and the end caps 2 connect the rod body The end faces of the body 1 are covered. The end plug 2 can facilitate operations such as assembly and maintenance of the fuel rod in the later stage. The end plug 2 can also be replaced with other components for operations such as assembling.

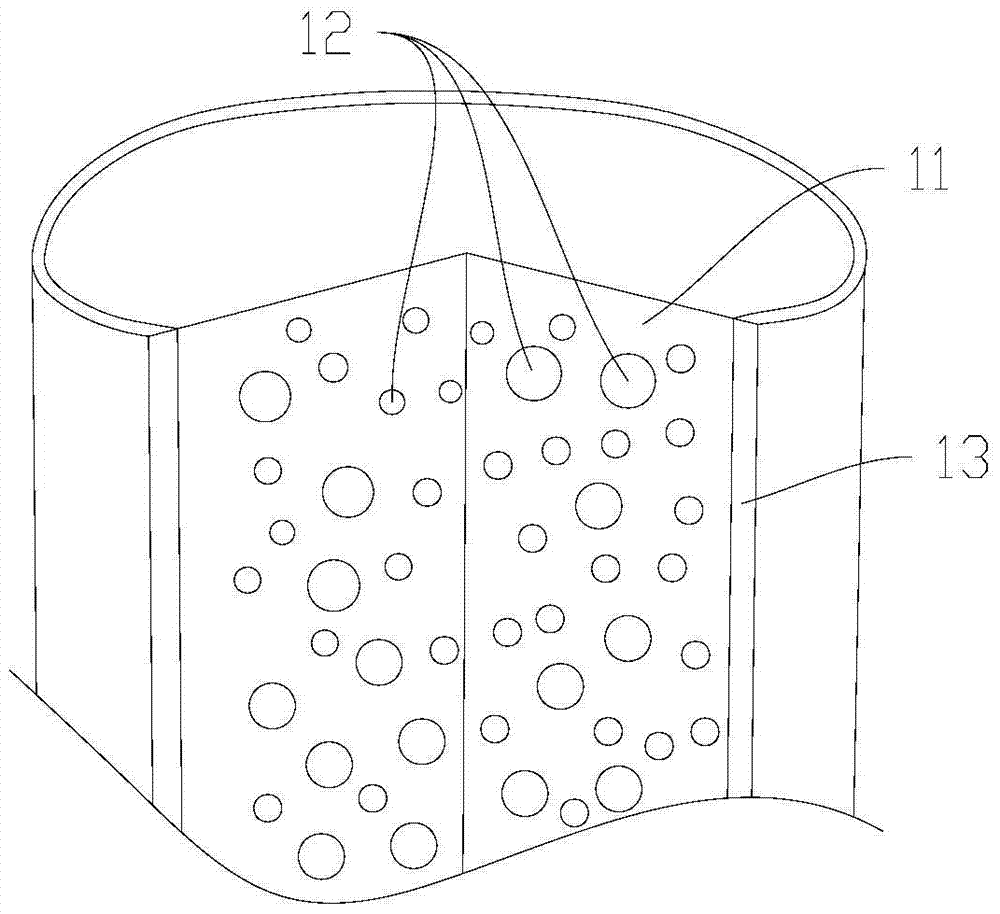

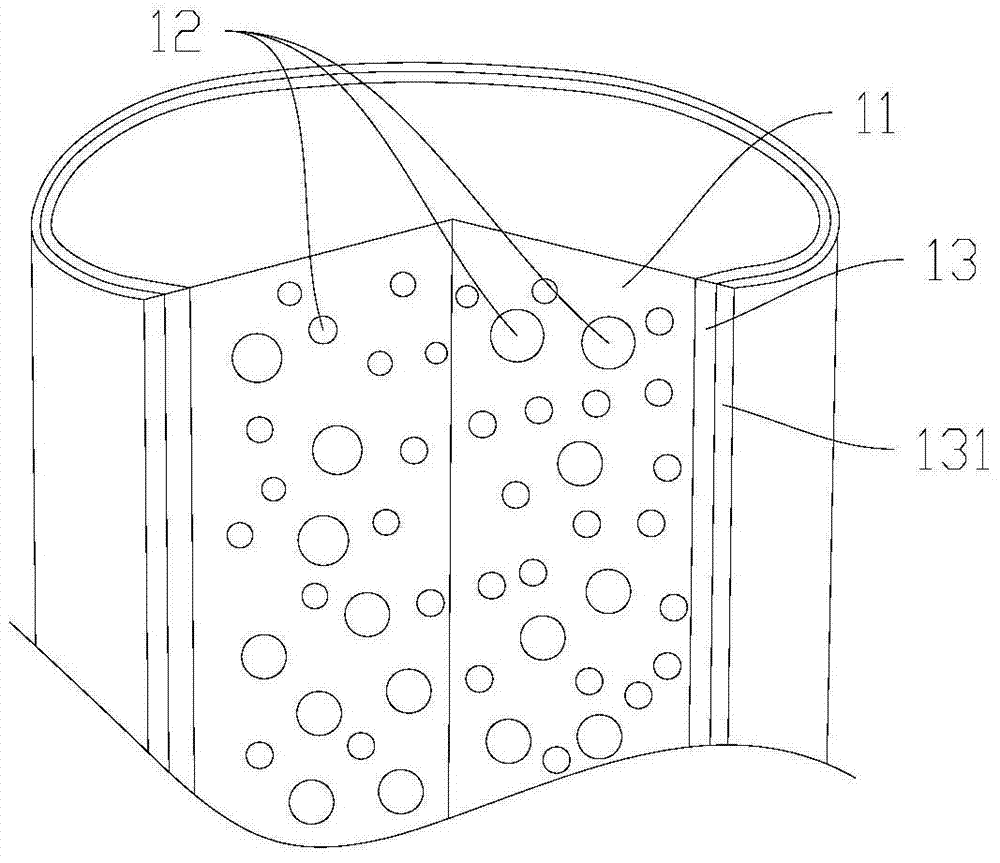

[0037] The rod body 1 includes a rod-shaped metal matrix 11 and fuel particles 12 dispersed in the metal matrix 11 . Further, the rod body 1 also includes a fue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com