Chamfer grinding device

A technology of chamfering device and clamping end, which is applied in the direction of grinding machine, grinding frame, grinding bed, etc., can solve the problems of poor process adaptability, damage to the accuracy of machine tool spindle, long processing cycle, etc., and achieve shortened processing Cycle time, fast installation, and simplified processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

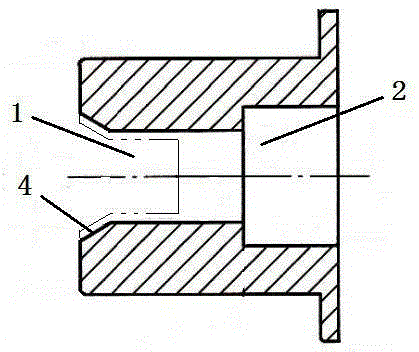

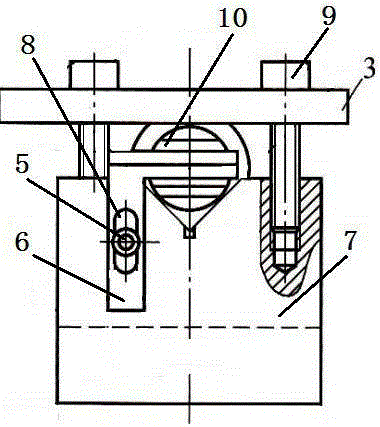

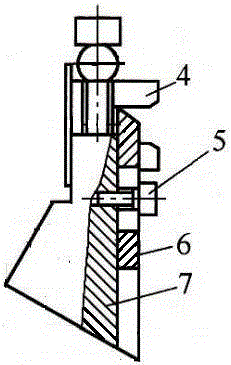

[0021] See attached figure 2 , 3 , Shown in 4, the chamfering device of the present invention comprises an L-shaped knife-edge block 6, a set screw 5, a hold-down bar 3, a hold-down screw 9 and a base 7; one end of the knife-edge block 6 has a waist-shaped groove 8, The other end is provided with a knife edge; the clamping end surface of the base 7 is provided with a V-shaped groove, and the bottom end surface of the base 7 is at an angle of 60° with the processing plane; 10 is compressed in the V-shaped groove of the base 7, the knife-edge end of the knife-edge block 6 is close to the upper groove surface of the workpiece 10, and the other end of the knife-edge block 6 is fixed on the base 7 through the waist-shaped groove 8 and the fixing screw 5 .

[0022] As a further improvement, the clamping end surface of the base 7 in the present invention is provided with a 90° V-shaped groove. Certainly also can be set as the V-shaped groove of other angle according to the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com