Method of preparing graphene with lignin solution

A technology of lignin and graphene, applied in the field of nanometers, to achieve the effect of promoting functionalization and high-value utilization, and solving the problem of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

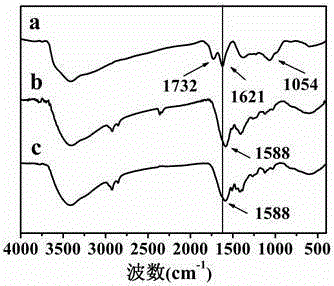

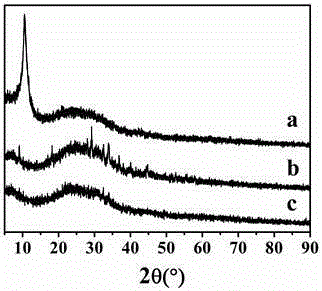

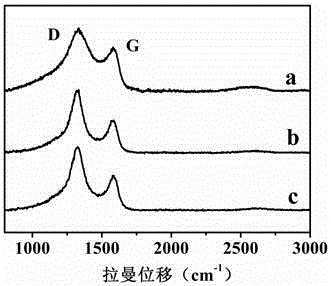

Embodiment 1

[0022] 0.080 g of graphene oxide was dissolved in deionized water to form an 8.0 mg / mL graphene oxide aqueous solution, which was ultrasonically dispersed and placed in a heating reactor. Dissolve 0.005g lignin in 0.5wt% NaOH solution, and stir to obtain 0.5mg / mL lignin solution. Adjust the temperature of the heating reactor to 30°C, and slowly drop the above-prepared lignin sodium hydroxide solution into the graphene oxide solution. At this time, the weight ratio of lignin to graphene oxide is about 1:16. Stable dispersed graphene was obtained after 2 h of reaction.

Embodiment 2

[0024] 0.040 g of graphene oxide was dissolved in deionized water to form a 4.0 mg / mL graphene oxide aqueous solution, which was ultrasonically dispersed and placed in a heating reactor. Dissolve 0.010g lignin in 1.0wt% NaOH solution and stir to obtain 1.0mg / mL lignin solution. Adjust the temperature of the heating reactor to 50°C, slowly drop the lignin sodium hydroxide solution prepared above into the graphene oxide solution, at this time the weight ratio of lignin to graphene oxide is about 1:4. Stable dispersed graphene was obtained after 4 h of reaction.

Embodiment 3

[0026] 0.020 g of graphene oxide was dissolved in deionized water to form a 2.0 mg / mL graphene oxide aqueous solution, which was ultrasonically dispersed and then placed in a heating reactor. Dissolve 0.020g lignin in 1.5wt% NaOH solution, and get 2.0mg / mL lignin solution after stirring. Adjust the temperature of the heating reactor to 70°C, and slowly drop the lignin sodium hydroxide solution prepared above into the graphene oxide solution. At this time, the weight ratio of lignin to graphene oxide is about 1:1. Stable dispersed graphene was obtained after 6 h of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com