A blast furnace floor protection system

A protection system and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as potential safety hazards and economic losses, and achieve the effects of convenient operation, good pressure effect, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

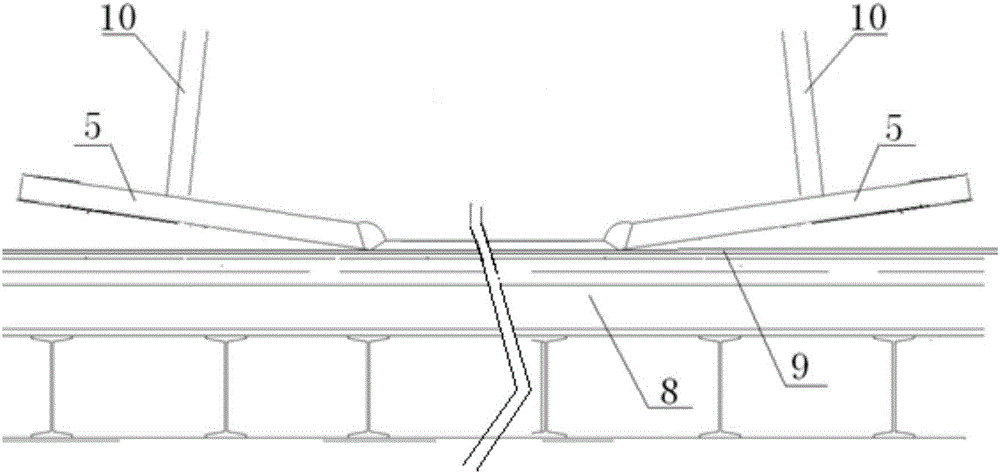

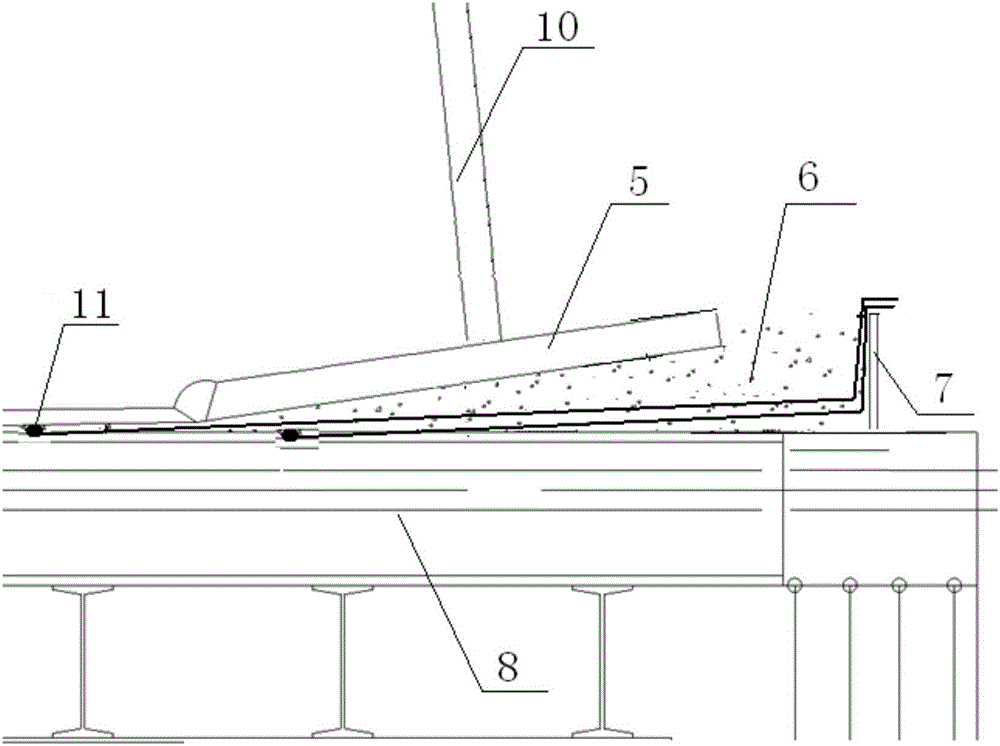

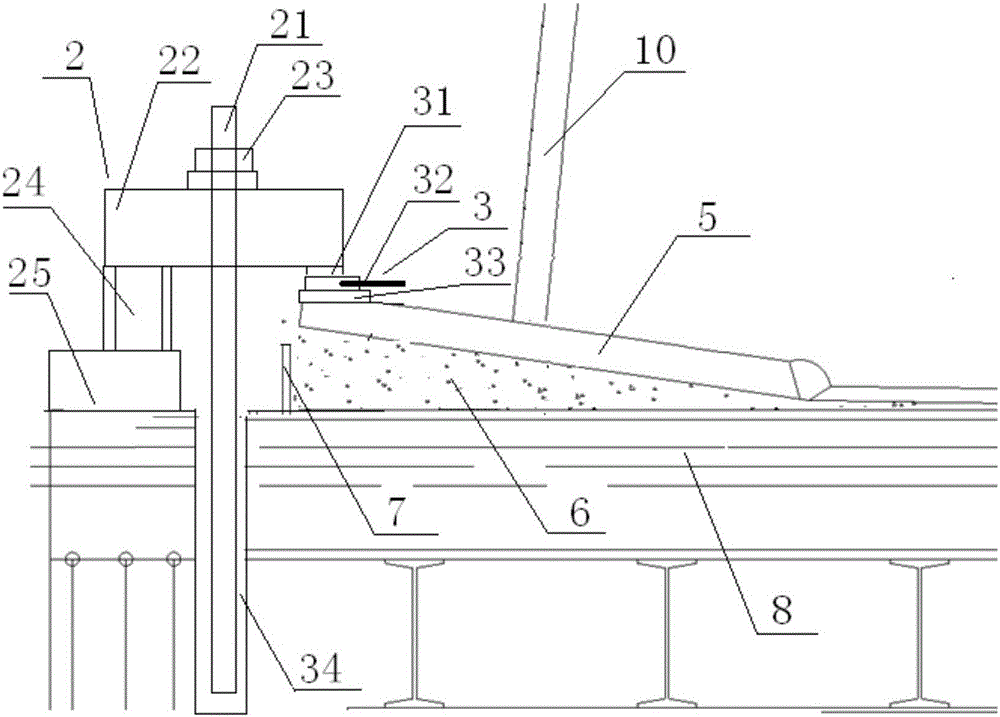

[0051] A blast furnace floor protection system in this embodiment includes a pressurizing device, a temperature sensor 11, a pressure sensing device 3 and a castable 6, wherein: the pressurizing device can be a pneumatic or hydraulic device, directly or through a pressure sensing device 3 acting on the upturned periphery of the upturned furnace bottom sealing plate 5; figure 2 As shown, the temperature sensor 11 is set in the gap between the furnace bottom H beam 9 and the upturned furnace bottom sealing plate 5; the castable 6 is filled between the furnace bottom H beam 9 and the upturned furnace bottom sealing plate 5 in the gap between. In this embodiment, the pressurizing device is an anchor bolt pressurizing device 2, including an embedded anchor bolt 21, a pressing plate A22, a nut A23 and a spacer 24; the bottom end of the embedded anchor bolt 21 is inserted on the outside of the blast furnace shell 10, In the foundation borehole 34 reserved for the blast furnace foun...

Embodiment 2

[0081] The basic structure of a blast furnace bottom protection system of the present embodiment is the same as that of the first embodiment. The improvement lies in that: before pouring the high thermal conductivity self-flowing castable, the pressing devices 4 are evenly distributed on the circumference of the bottom surface of the blast furnace, such as Figure 5 As shown, the cross section of the main body of the pressing device 4 is in the shape of a left and right asymmetric "earth" shape, including a pressing plate B43 and a base plate 44 that are parallel to each other, and a bolt 41 that is fixedly connected to the base plate 44 after passing through the pressing plate B43; The nut B42 adjusts the height of the pressing plate B43; the base plate 44 is inserted into the bottom of the upturned furnace bottom sealing plate 5 and the furnace bottom H beam 9 is fixedly connected by welding, and is pressed by the pressing plate B43 on the upturned periphery of the upturned fu...

Embodiment 3

[0085] The basic structure of a blast furnace bottom protection system of this embodiment is the same as that of Embodiment 2, and a pressing device 4 can be used to replace the anchor bolt pressing device 2 directly acting on the bottom sealing plate 5 of the upturned furnace; Adjusted again: SiC, 85 parts; aqueous binder, 20 parts; corundum, 19 parts; water reducing agent and dispersant, 1 part in total. Through testing, its thermal conductivity {100℃, (200℃×24h)} is 12w / m.k, and its strength grade is C40. After testing, the indicators also meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com