Heating quenching inductor with different heat distributions

A quenching inductor and heat distribution technology, applied in the field of quenching inductors, can solve the problems of reducing the processing efficiency of web-type gears, increasing the manufacturing cost, increasing the machining allowance, etc., so as to save the grinding process, improve the production efficiency, reduce the The effect of small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

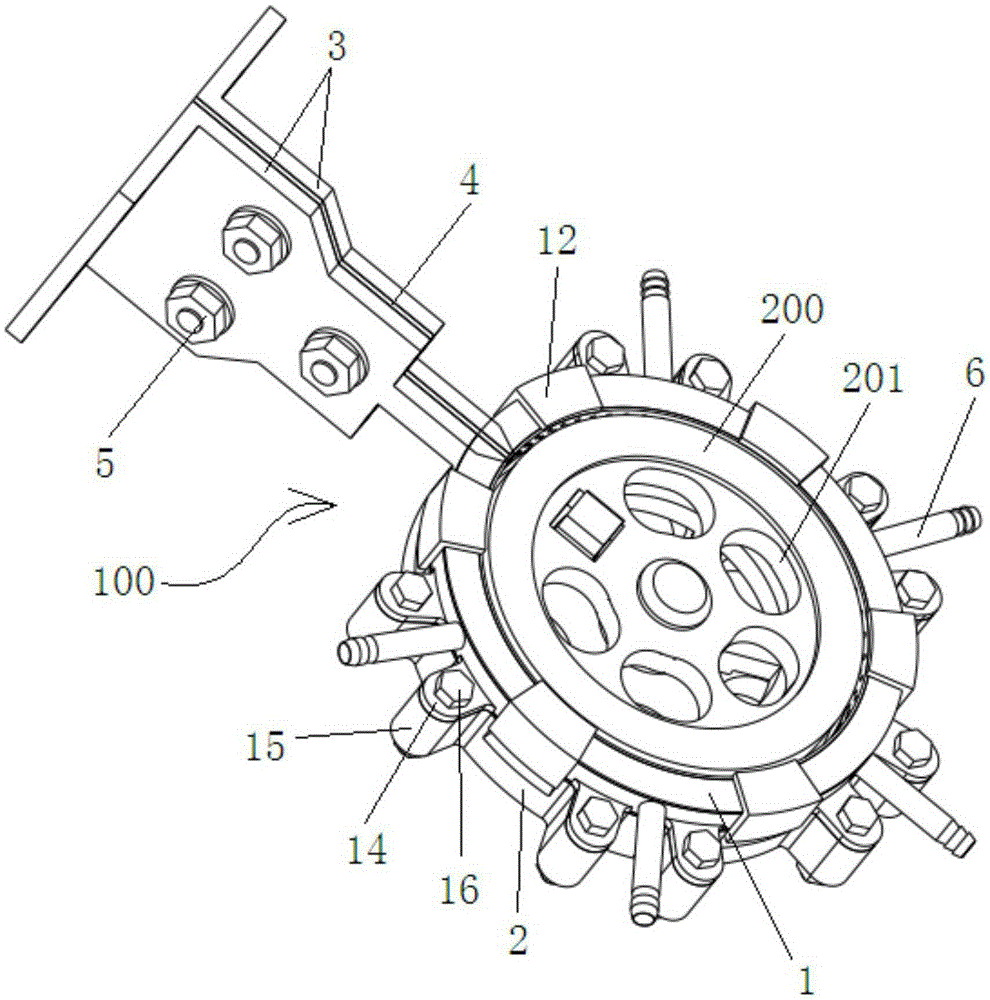

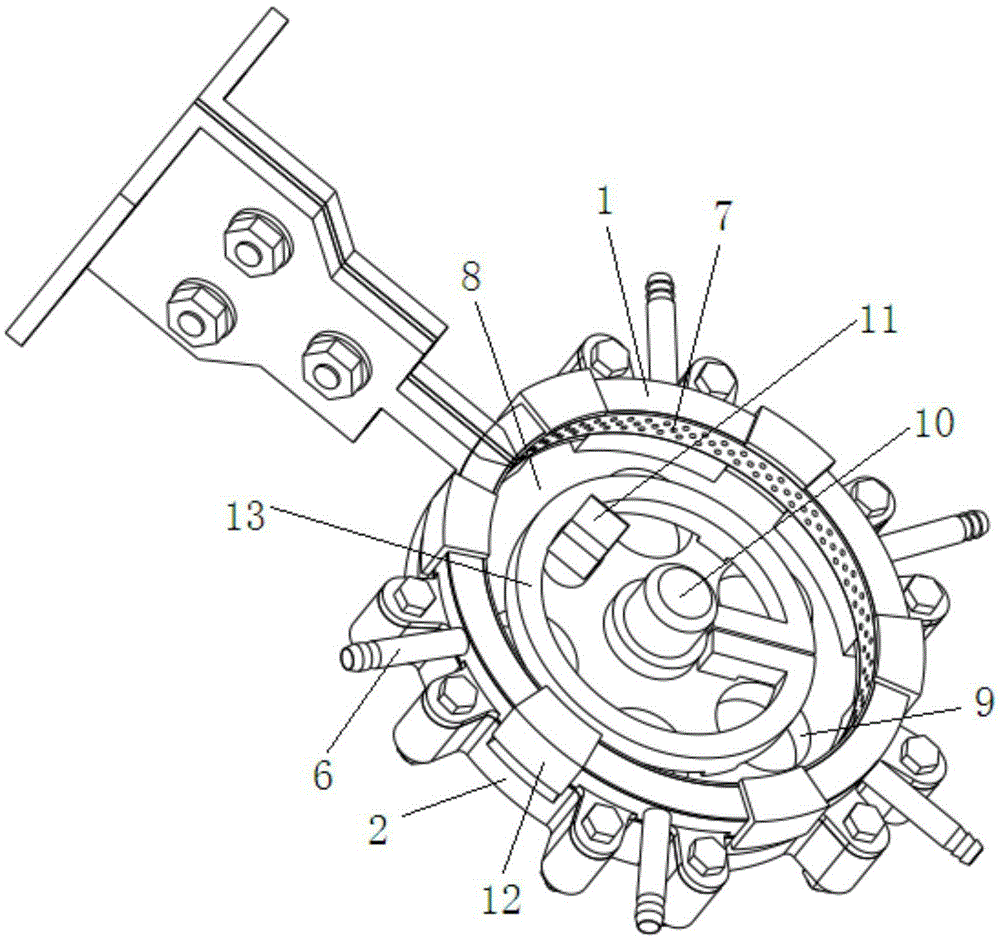

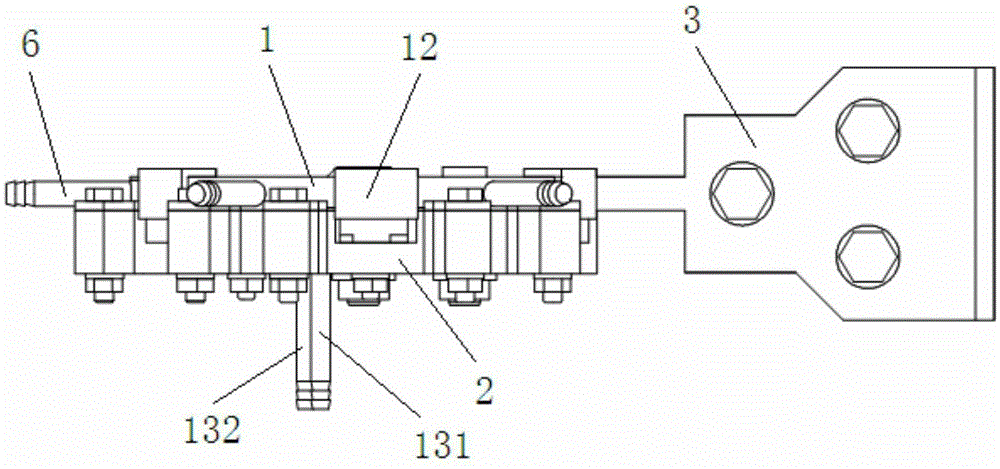

[0025] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 3 The technical solution provided by the present invention is described in detail.

[0026] figure 1 It is a perspective view of the heating and quenching inductor with different heat distribution provided in the embodiment of the present invention; figure 2 It is the usage state diagram of the heating and quenching inductor provided in the embodiment of the present invention. Such as figure 1 and figure 2 In the shown embodiment, the heating and quenching inductor 100 with different heat distribution is used for quenching the web-type gear 200 with several weight-reducing holes evenly opened, and the heating and quenching inductor 100 includes: an annular effective heating ring 1 And an insulating support frame 2. Wherein, the annular effective heating ring 1 is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com