Cold-bent thin-walled steel-keel combined shear wall with steel skin

A cold-formed thin-walled section steel and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as failure of screws at joints, damage to wall panels, etc., to improve the fire protection effect, improve the lateral bearing capacity and Stiffness, the effect of avoiding the cold bridge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

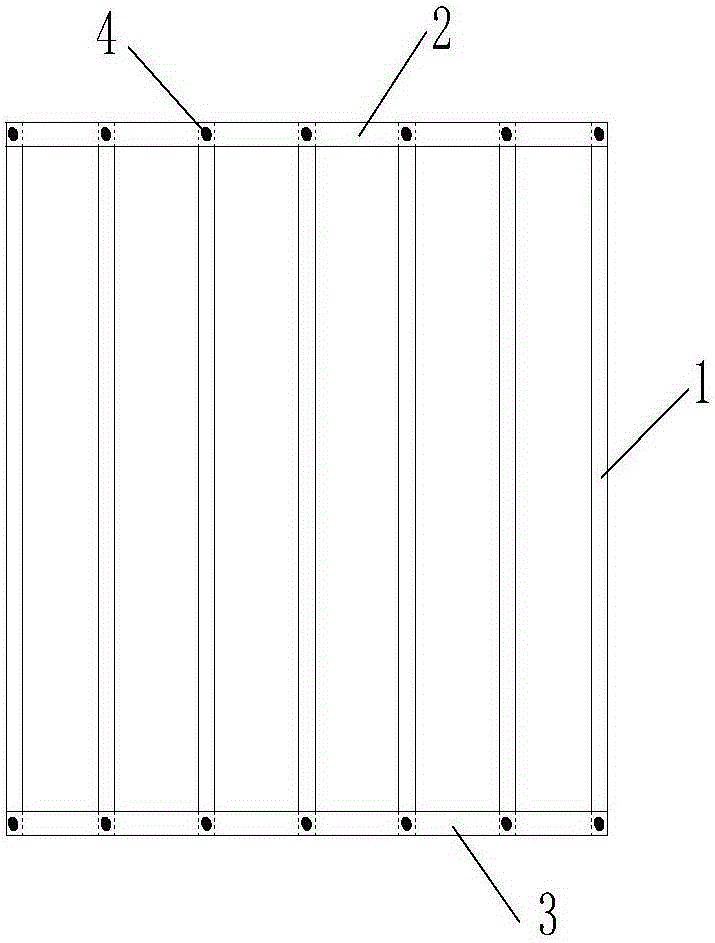

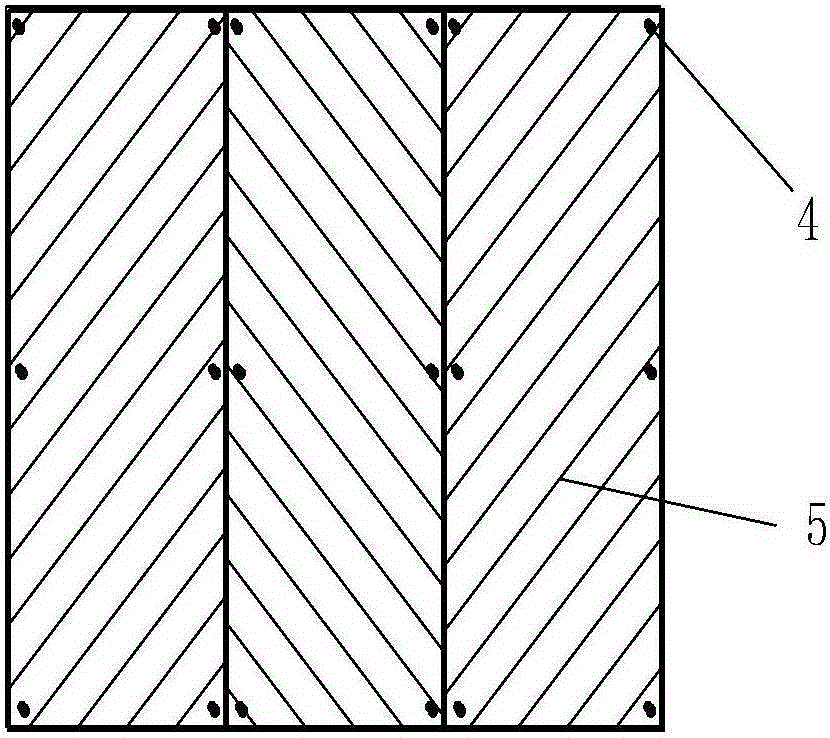

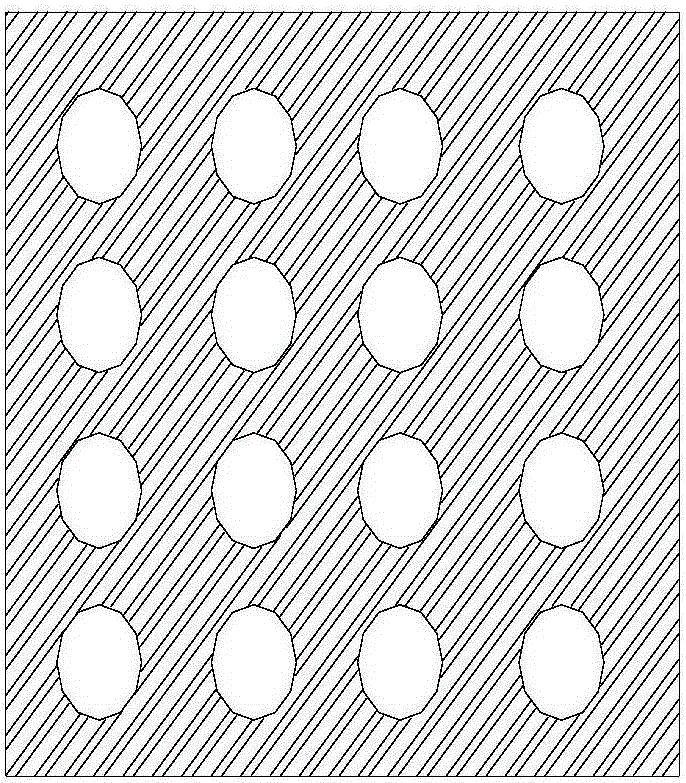

[0021] The cold-formed thin-walled steel keel composite shear wall of the present invention is mainly composed of a cold-formed thin-walled steel keel skeleton and wall panels. Such as figure 1 As shown, the cold-formed thin-walled steel keel skeleton is formed by the cold-formed thin-walled steel keel column 1 , the cold-formed thin-walled steel upper guide rail 2 and the lower guide rail 3 connected to each other by self-tapping screws 4 . Cold-formed thin-walled steel keel column 1 can choose single C-section column or back-to-back double C-section column according to the load level; the distance between keel columns is generally 600mm or 400mm. Then install a layer of base wall panels on both sides of the keel frame (such as figure 2 As shown), the size of the wall panel 5 is generally 3000mm×1200mm×12mm, the direction of the long side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com