Single-tube-replaceable low-temperature economizer with high sealing performance

A low-temperature economizer and high-sealing technology, applied in feed water heaters, preheating, steam generation, etc., can solve the problems of high equipment cost and maintenance cost, increased cycle efficiency of power plants, easy ash accumulation in heat exchange tube bundles, etc. problem, to achieve the effect of convenient and quick replacement, uniform distribution of flue gas flow rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

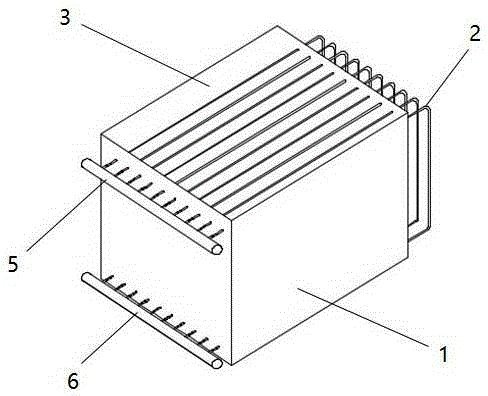

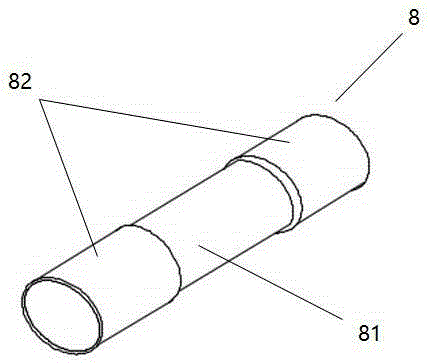

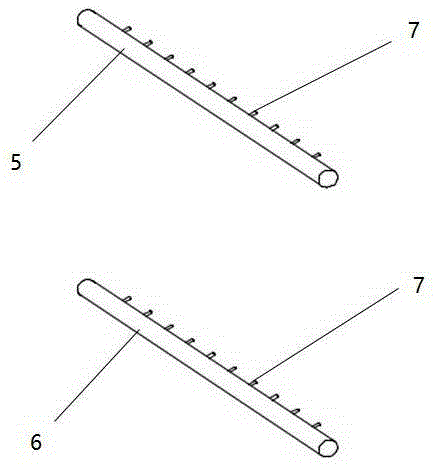

[0027] Embodiment 1: A high-tight single-tube replaceable low-temperature economizer, including a shell 1 and a U-shaped heat exchange tube 2; hole, the straight tube part of the U-shaped heat exchange tube 2 is inserted into the installation hole, and the end of the straight tube part of the U-shaped heat exchange tube 2 protrudes from the installation hole on the other side of the housing 1; The heat exchange tubes 2 are neatly arranged, and the straight tube parts of the U-shaped heat exchange tubes 2 form the upper heat exchange tube row 3 and the lower heat exchange tube row 4; the upper end of the side of the shell 1 is provided with an upper header 5; The lower end of the side of the housing 1 is provided with a lower header 6; the upper header 5 is connected to the water outlet of the low-temperature economizer; the lower header 6 is connected to the water inlet of the low-temperature economizer; Both the header 5 and the lower header 6 are provided with a plurality of...

Embodiment 2

[0028] Embodiment 2: A high-tight single-tube replaceable low-temperature economizer, including a shell 1 and a U-shaped heat exchange tube 2; hole, the straight tube part of the U-shaped heat exchange tube 2 is inserted into the installation hole, and the end of the straight tube part of the U-shaped heat exchange tube 2 protrudes from the installation hole on the other side of the housing 1; The heat exchange tubes 2 are neatly arranged, and the straight tube parts of the U-shaped heat exchange tubes 2 form the upper heat exchange tube row 3 and the lower heat exchange tube row 4; the upper end of the side of the shell 1 is provided with an upper header 5; The lower end of the side of the housing 1 is provided with a lower header 6; the upper header 5 is connected to the water outlet of the low-temperature economizer; the lower header 6 is connected to the water inlet of the low-temperature economizer; Both the header 5 and the lower header 6 are provided with a plurality of...

Embodiment 3

[0029] Embodiment 3: A replaceable low-temperature economizer with a single tube with high sealing performance, including a shell 1 and a U-shaped heat exchange tube 2; hole, the straight tube part of the U-shaped heat exchange tube 2 is inserted into the installation hole, and the end of the straight tube part of the U-shaped heat exchange tube 2 protrudes from the installation hole on the other side of the housing 1; The heat exchange tubes 2 are neatly arranged, and the straight tube parts of the U-shaped heat exchange tubes 2 form the upper heat exchange tube row 3 and the lower heat exchange tube row 4; the upper end of the side of the shell 1 is provided with an upper header 5; The lower end of the side of the housing 1 is provided with a lower header 6; the upper header 5 is connected to the water outlet of the low-temperature economizer; the lower header 6 is connected to the water inlet of the low-temperature economizer; Both the header 5 and the lower header 6 are pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com