Solid phase extraction column capable of achieving negative pressure suction and using method

A solid-phase extraction column and negative pressure suction technology, applied in separation methods, chemical instruments and methods, selective adsorption, etc., can solve the problems of complicated operation steps, high equipment cost, slow extraction speed, etc., and achieve small volume and cost. Inexpensive, solvent-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

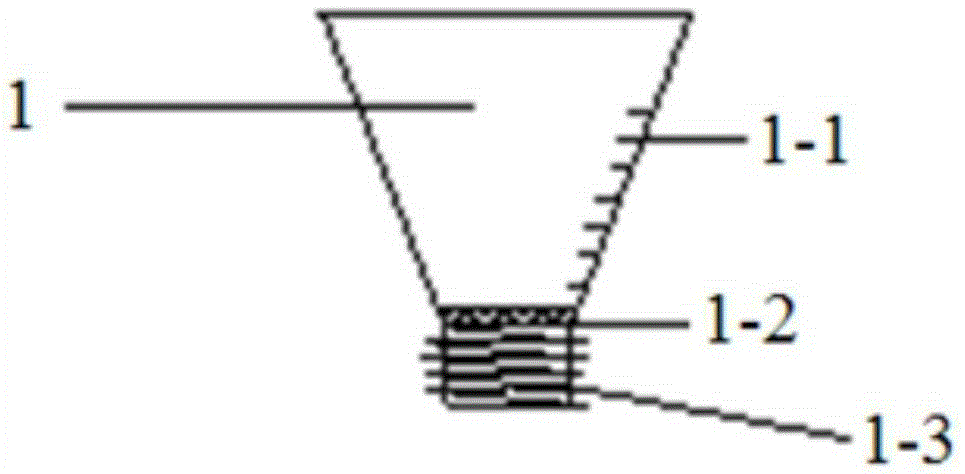

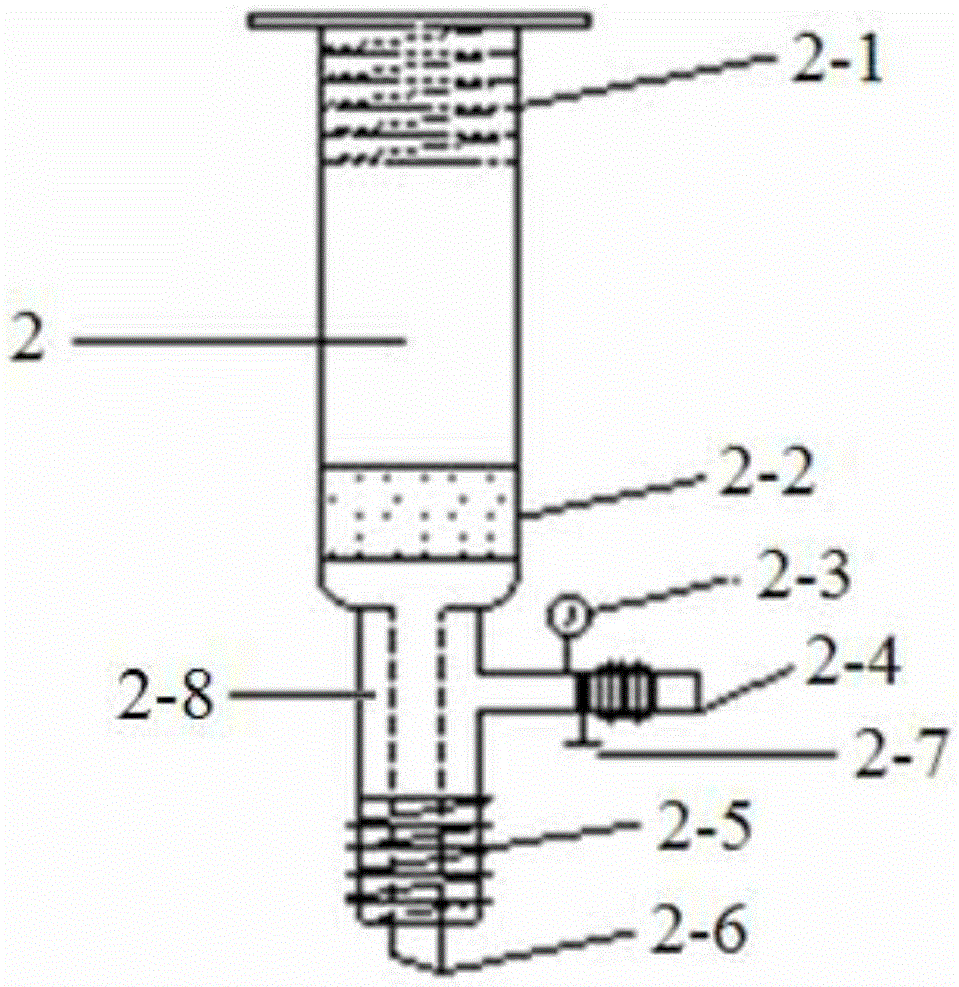

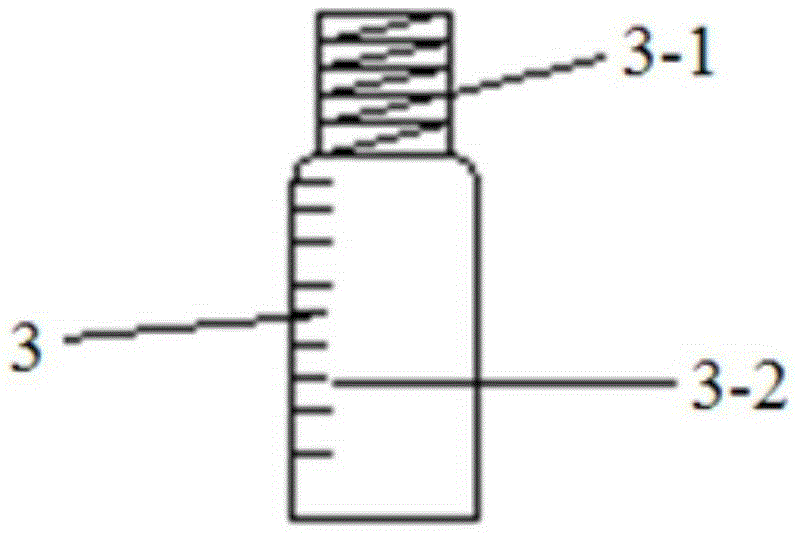

[0022] Embodiment 1: This embodiment is a solid-phase extraction column capable of negative pressure suction, including a liquid storage bottle 1, an adsorption packing column 2 and a collection bottle 3; Adopt threaded connection between, adopt threaded connection between described adsorption packing column 2 and collecting bottle 3;

[0023] The liquid storage bottle 1 includes a liquid storage bottle scale part 1-1, a filter device 1-2 and a liquid storage bottle external thread part 1-3;

[0024] The liquid storage bottle 1 is an Erlenmeyer bottle body, and the lower end of the liquid storage bottle 1 is provided with an external threaded portion 1-3 of the liquid storage bottle for threaded connection with the adsorption packing column 2, and the surface of the liquid storage bottle 1 is engraved There is a liquid storage bottle scale part 1-1 for representing the liquid volume in the liquid storage bottle 1, and a filter device 1-2 is provided at the inner bottom of the ...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the filter device 1-2 is formed by superimposing the filter screen on the upper filter membrane, the filter screen is a stainless steel filter screen, and the filter screen is made of stainless steel. The filter membrane used is microfiltration membrane, ultrafiltration membrane or nanofiltration membrane. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the top of the external threaded part 1-3 of the liquid storage bottle is provided with a sealing gasket, and the sealing gasket is a rubber O-ring. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com