Adhesive combined vertical roller

A vertical roller and gluing technology, which is applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve the problems of vertical roller expansion and cracking, and achieve the effects of uniform force, stable holding force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

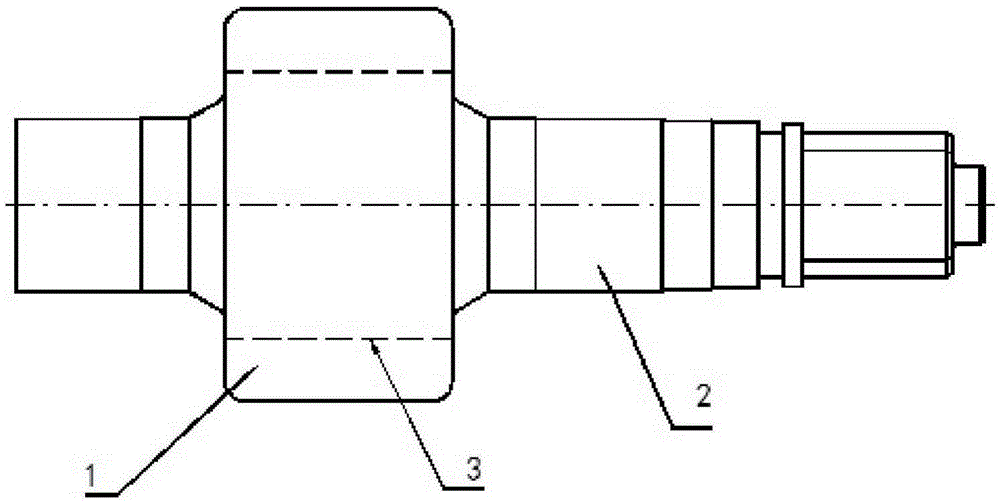

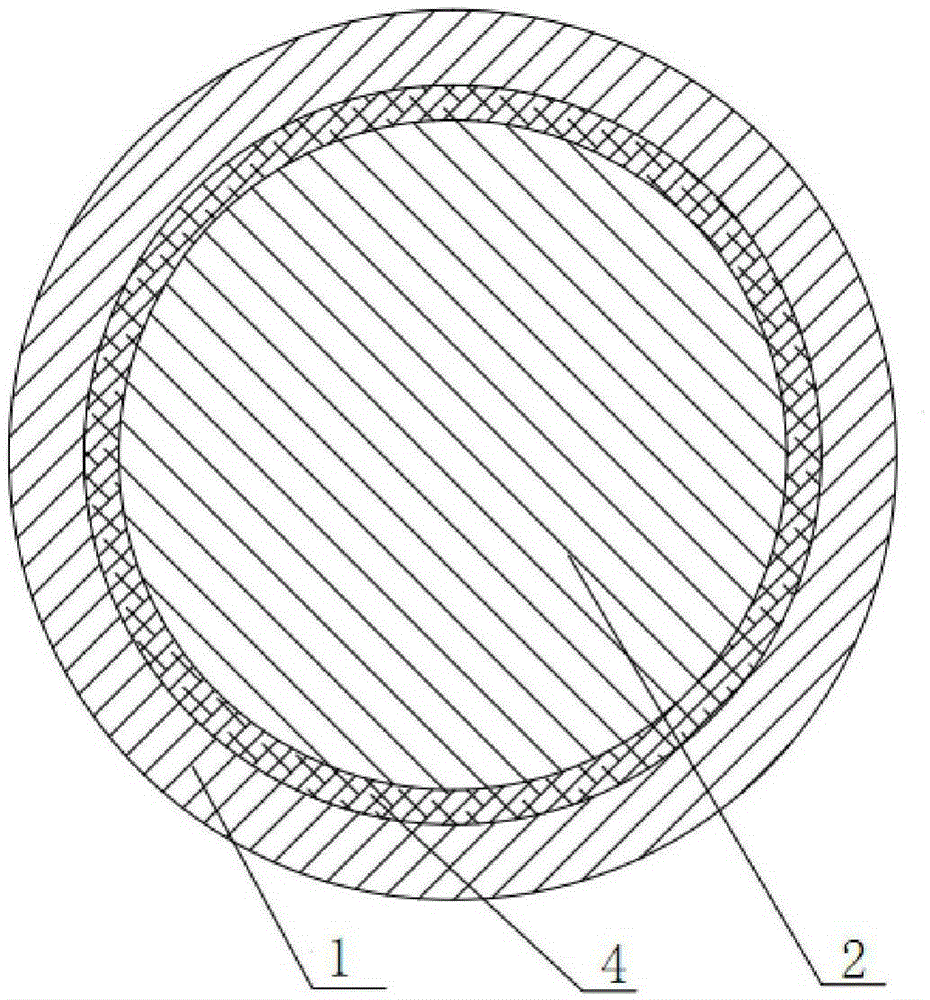

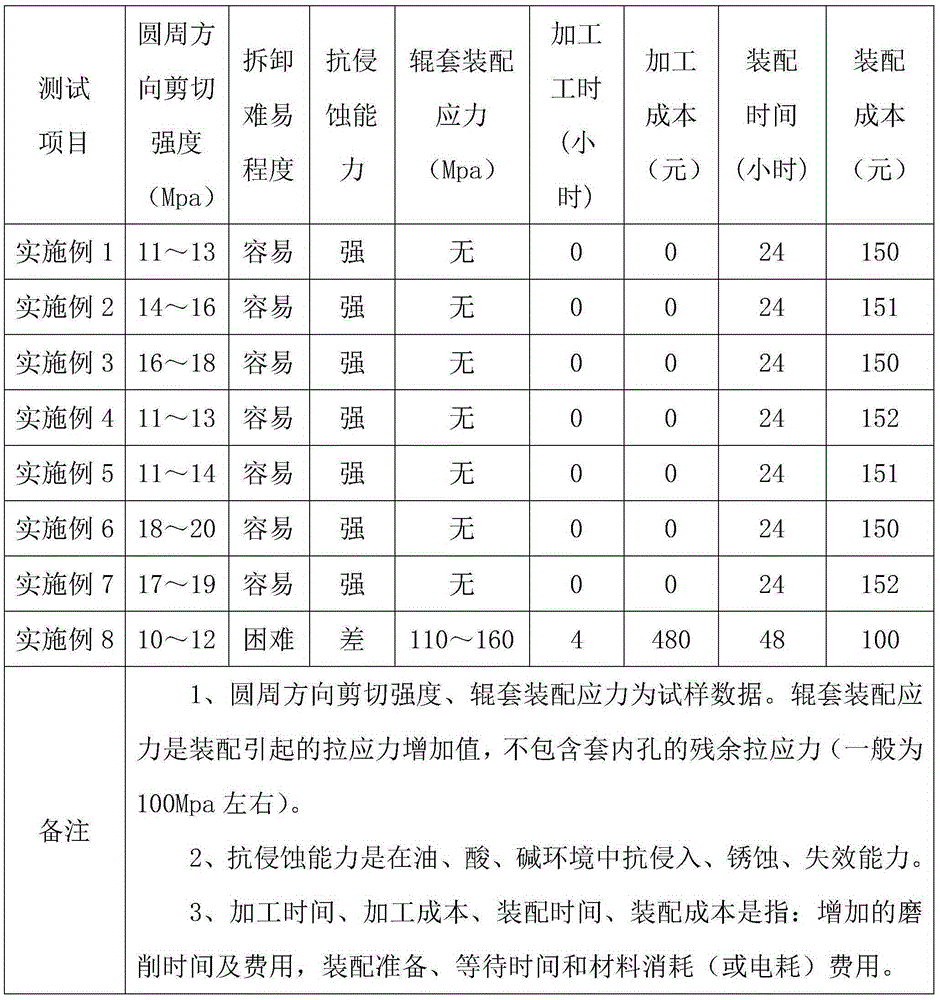

[0021] Such as figure 1 and figure 2 As shown, an adhesive combined vertical roller includes a roller sleeve 1 and a shaft core 2, and the roller sleeve 1 and the shaft core 2 are bonded and fixed by a cylindrical part holding glue 4, and the cylindrical part holding glue 4 is methacrylic acid Ester retaining rubber is produced by Hubei Huitian Rubber Industry Co., Ltd. The working temperature of the cylindrical parts holding glue 4 is -55-150°C, the shear strength is 15-32MPa, the viscosity is 125-7500mPa·s, the filling gap is 0.05-0.1mm, the initial solidification time is 10min, and the performance is good , a wide range of applications; the surface roughness of the joint surface 3 of the roller sleeve 1 and the shaft core 2 is Ra0.8.

[0022] The method of use is as follows: Remove oil, dust, and rust from the surface of the joint surface 3 of the roller sleeve 1 and the shaft core 2, clean it with 755 surface treatment agent and dry it (755 surface treatment agent is a ...

Embodiment 2

[0025] The difference between this embodiment and embodiment 1 is that the cylindrical parts holding glue 4 with a filling gap of 0.25-0.3 mm is used, that is, the gap between the joint surface 3 of the roller sleeve 1 and the shaft core 2 is 0.25-0.3 mm.

Embodiment 3

[0027] The difference between this example and Example 1 is: the surface roughness of the joint surface 3 of the roller sleeve 1 and the shaft core 2 is Ra6.2, and the joint surface 3 with the middle roughness is selected to test the performance of the assembly after the holding is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com