Polypropylene/ nickel plated glass fiber/ titanium dioxide composite material and preparation method thereof

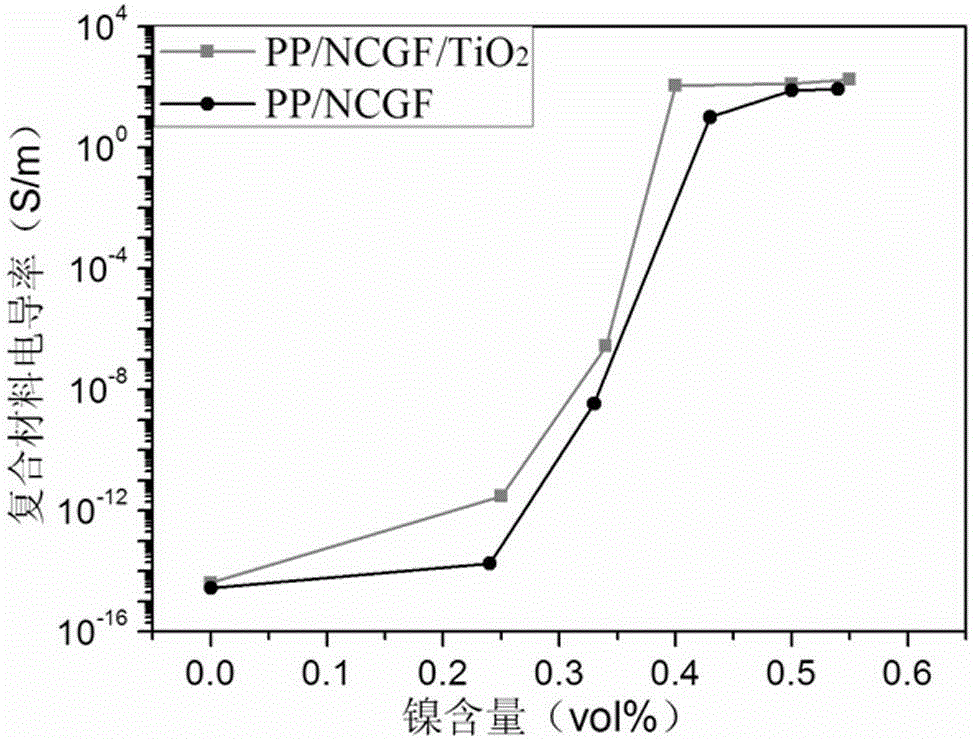

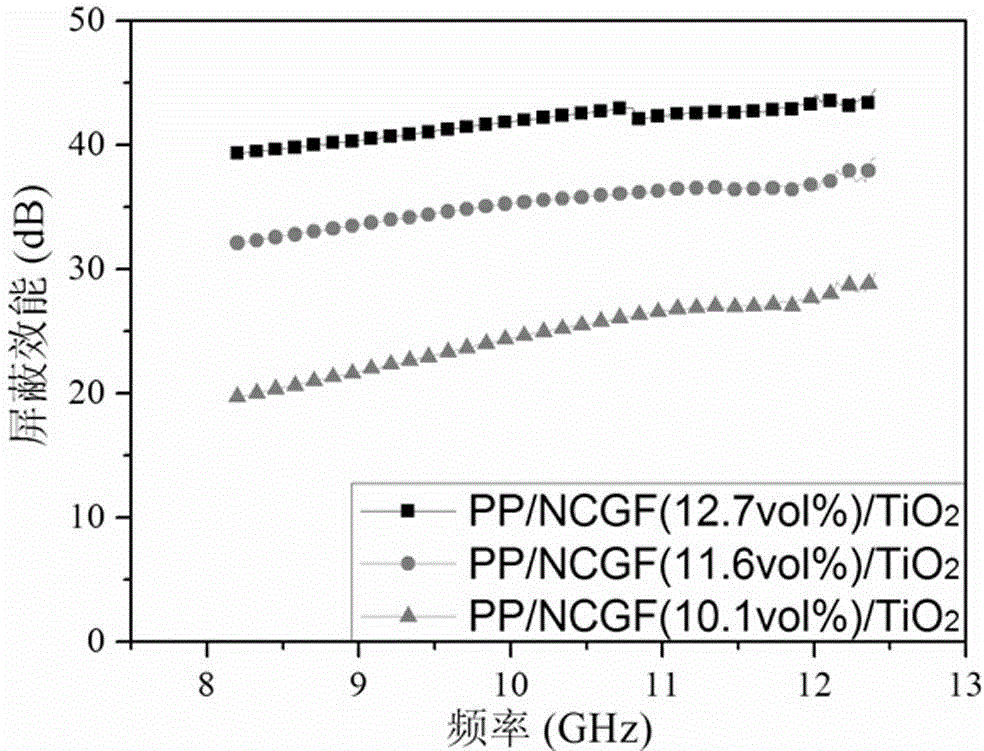

A technology of titanium dioxide and glass fiber is applied in the field of polypropylene/nickel-plated glass fiber/titanium dioxide composite material and its preparation, which can solve the problems of high cost and low production efficiency of conductive polymer materials, achieve low cost and improve electromagnetic shielding efficiency. , the effect of good electrical conductivity and electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

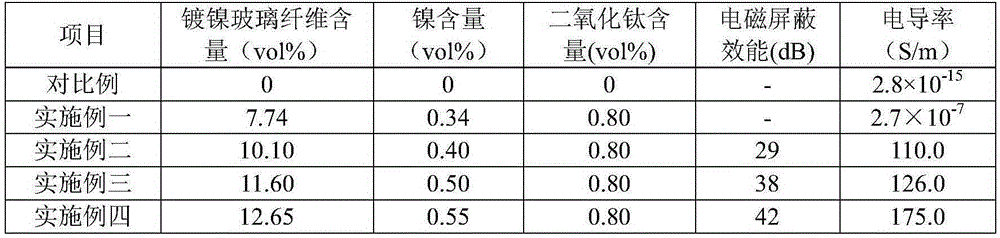

Embodiment 1

[0016] The preparation method of polypropylene / nickel-plated glass fiber / titanium dioxide electromagnetic shielding functional composite material comprises the following steps:

[0017] (1) First raise the temperature of the torque rheometer to 200 ° C, add 38.5 g of polypropylene to it, banbury for 5 minutes, and rotate at 60 rpm to fully melt the polypropylene;

[0018] (2) Add 1.5g of nano-titanium dioxide to the torque rheometer, knead for 10min, and make the two uniformly mix;

[0019] (3) Add 10g nickel-plated glass fiber to the torque rheometer again, make the volume ratio of polypropylene and nickel-plated glass fiber and nano-titanium dioxide be 91.46:7.74:0.8 and mix 10min, obtain the evenly dispersed mixture;

[0020] (4) Hot pressing the mixture obtained in step (3) under the conditions of 190° C. and 10 MPa to obtain a polypropylene / nickel-plated glass fiber / titanium dioxide composite material.

Embodiment 2

[0022] The preparation method of polypropylene / nickel-plated glass fiber / titanium dioxide electromagnetic shielding functional composite material comprises the following steps:

[0023] (1) First raise the temperature of the torque rheometer to 200°C, add 36g of polypropylene to it, and banbury for 5 minutes at a speed of 60rpm to fully melt the polypropylene;

[0024] (2) Add 1.5g of nano-titanium dioxide to the torque rheometer, knead for 10min, and make the two uniformly mix;

[0025] (3) add 12.5g nickel-plated glass fibers in the torque rheometer again, make the volume ratio of polypropylene and nickel-plated glass fibers and nano-titanium dioxide be 89.10:10.10:0.8, mix 10min, obtain the homogeneously dispersed mixture;

[0026] (4) The mixture obtained in step (3) was hot-pressed at 190° C. and 10 MPa to obtain a polypropylene / nickel-plated glass fiber / titanium dioxide composite material with high electrical conductivity and electromagnetic shielding performance.

Embodiment 3

[0028] The preparation method of polypropylene / nickel-plated glass fiber / titanium dioxide electromagnetic shielding functional composite material comprises the following steps:

[0029] (1) First raise the temperature of the torque rheometer to 200 ° C, add 34.5 g of polypropylene to it, banbury for 5 minutes, and rotate at 60 rpm to fully melt the polypropylene;

[0030] (2) Add 1.5g of nano-titanium dioxide to the torque rheometer, knead for 10min, and make the two uniformly mix;

[0031] (3) add 14g nickel-plated glass fiber to the torque rheometer again, make the volume ratio of polypropylene and nickel-plated glass fiber and nano-titanium dioxide be 87.60:11.60:0.8, mix 10min, obtain the uniformly dispersed mixture;

[0032] (4) The mixture obtained in step (3) was hot-pressed at 190° C. and 10 MPa to obtain a polypropylene / nickel-plated glass fiber / titanium dioxide composite material with high electrical conductivity and electromagnetic shielding performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com