Flame-retardant epoxy grout used for joint filling and leakage stopping

A technology of epoxy cement and epoxy resin, which is applied in the field of caulking and plugging materials, can solve the problems of unsatisfactory flame retardant effect, poor corrosion resistance, inconvenient construction, etc., achieve good bonding effect, reduce production cost, reduce The effect of sticky chirality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

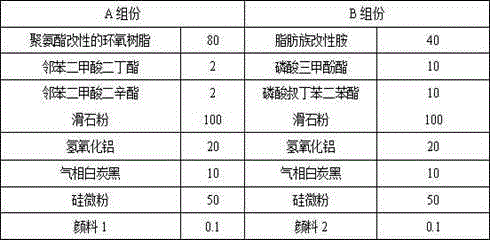

[0018] Embodiment 1: A kind of flame-retardant epoxy mastic used for caulking and plugging is composed of two components A and B with different colors, and is listed in the following table by mass parts:

[0019]

[0020] In this embodiment, the epoxy equivalent of the polyurethane-modified epoxy resin is 210-230 g / mol, and the amine equivalent of the aliphatic modified amine is 100-120 g / mol. Pigment 1 and Pigment 2 are different colors.

[0021] In this embodiment, the two components A and B are combined and cured at a mass ratio of 1:0.9. The construction time is 2 hours, and it will be completely cured after 24 hours.

Embodiment 2

[0022] Embodiment 2: A kind of flame-retardant epoxy mastic used for caulking and plugging consists of two components A and B with different colors, listed in the following table by mass parts:

[0023]

[0024] In this embodiment, the epoxy equivalent of the unmodified epoxy resin is 190-220 g / mol, and the amine equivalent of the alicyclic modified amine is 100-110 g / mol. Pigment 1 and Pigment 2 are different colors.

[0025] In this embodiment, the two components A and B are co-cured with a mass ratio of 1:1. The construction time is 1.5h, and it will be completely cured after 24h.

Embodiment 3

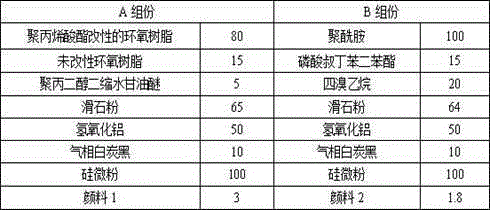

[0026] Embodiment 3: A kind of flame-retardant epoxy mastic used for caulking and plugging consists of two components A and B with different colors, listed in the following table by mass parts:

[0027]

[0028] In this embodiment, the epoxy equivalent of the acrylate-modified epoxy resin is 210~230g / mol, the epoxy equivalent of the unmodified epoxy resin is 190~220g / mol, and the ring of polypropylene glycol diglycidyl ether The oxygen equivalent is 650~770g / mol, and the amine equivalent of polyamide is 200~230g / mol. Pigment 1 and Pigment 2 are different colors.

[0029] In this embodiment, the two components A and B are combined and cured at a mass ratio of 1:1.1. The construction time is 8 hours, and it will be completely cured after 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com