Concentration method for aroma components of West Lake Longjing Tea

An aroma component, Longjing green tea technology, applied in the field of food science, can solve the problems of difficult analysis of trace components, easy loss of aroma substances, high experimental components, etc., to achieve the effect of reduced loss, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

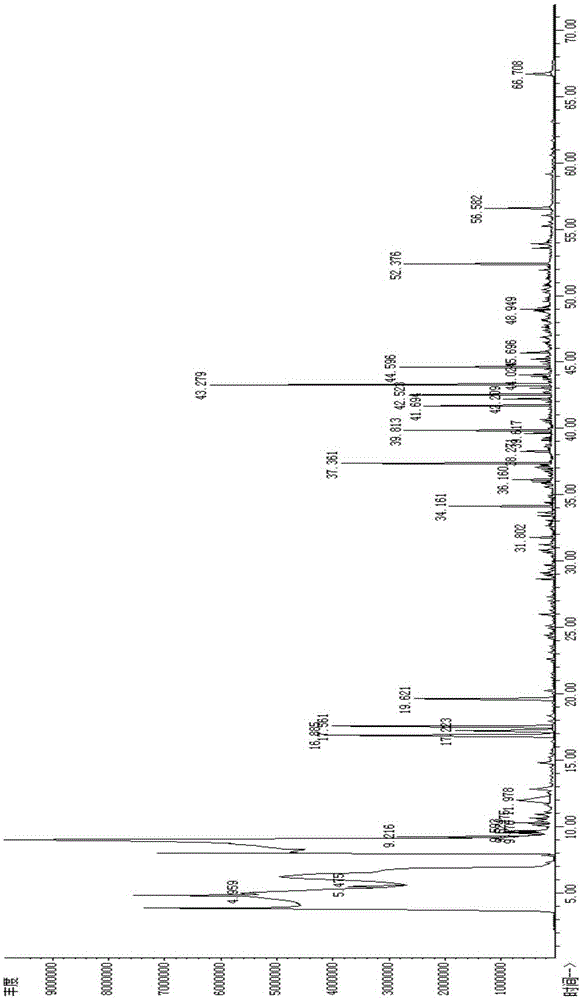

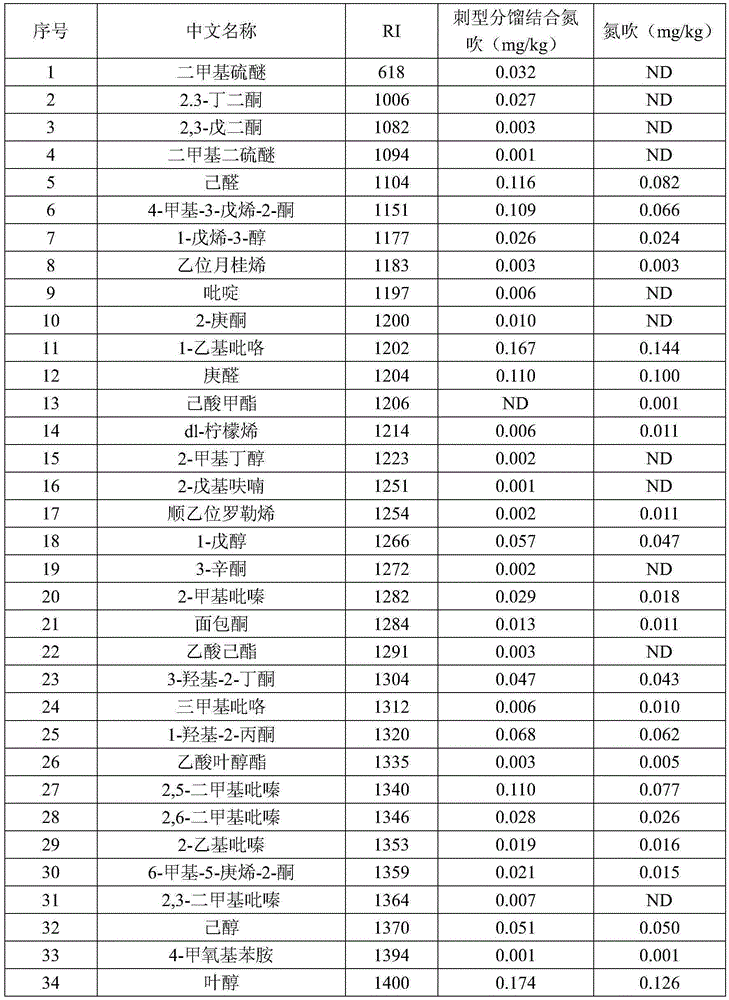

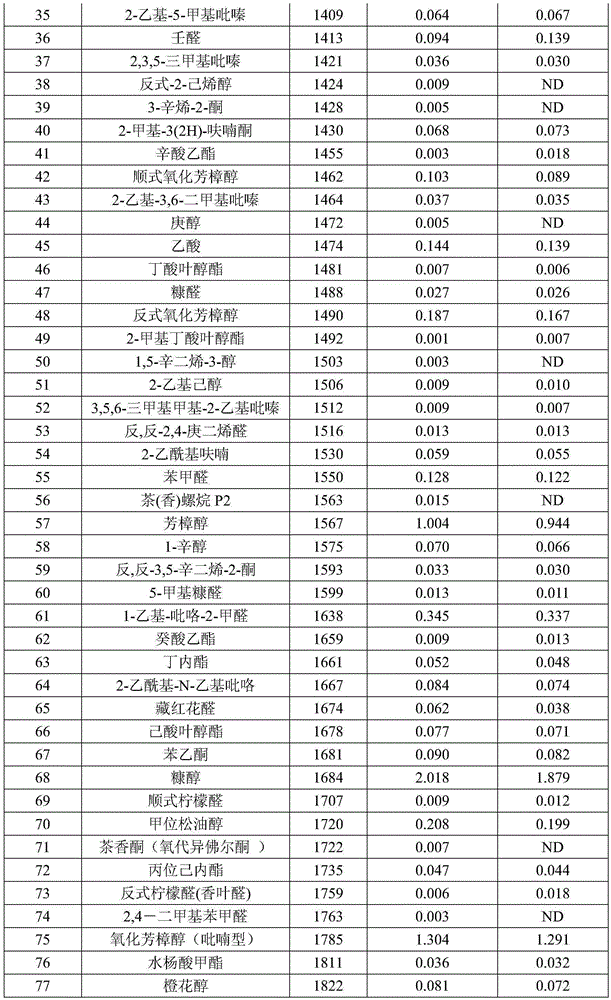

Image

Examples

Embodiment 1

[0016] 1) Crude extraction by water distillation: Take 30g of a commercially available West Lake Longjing green tea in a sample bottle, measure 400mL of pure water in the distillation bottle, heat the water to boil, pass the water vapor through the tea leaves, and the aroma components of the tea leaves will distill with the water vapor out, enter the condenser to condense, and obtain an aqueous solution containing aroma substances. Start timing until there are liquid droplets dripping in the condensation tube, the distillation process lasts for 30 minutes, and collect the distillate.

[0017] 2) Composite solvent extraction: add dichloromethane, diethyl ether and pentane to the distillate at a volume ratio of 1:1:1, extract three times (20mL, 20mL, 20mL) continuously, and extract the organic phase at 3500r / min Centrifuge for 20 minutes, take the upper organic phase, add anhydrous sodium sulfate to the organic phase to remove water, and filter the organic phase with 0.22 μm fil...

Embodiment 2

[0029] 1) Crude extraction by water distillation: Take 30g of a commercially available West Lake Longjing green tea in a sample bottle, measure 400mL of pure water in the distillation bottle, heat the water to boil, pass the water vapor through the tea leaves, and the aroma components of the tea leaves will distill with the water vapor out, enter the condenser to condense, and obtain an aqueous solution containing aroma substances. Start timing until there are liquid droplets dripping in the condensation tube, the distillation process lasts for 40min, and collect the distillate.

[0030] 2) Composite solvent extraction: add dichloromethane, diethyl ether and pentane mixed liquid volume ratio 1:1:1 to the distillate, extract continuously five times (20mL, 20mL, 20mL, 20mL, 20mL), the organic phase in Centrifuge at 4000r / min for 15 minutes, take the upper organic phase, add anhydrous sodium sulfate to the organic phase to remove water, and filter the organic phase with a 0.22 μm...

Embodiment 3

[0042] 1) Crude extraction by water distillation: Take 30g of a commercially available West Lake Longjing green tea in a sample bottle, measure 400mL of pure water in the distillation bottle, heat the water to boil, pass the water vapor through the tea leaves, and the aroma components of the tea leaves will distill with the water vapor out, enter the condenser to condense, and obtain an aqueous solution containing aroma substances. Start timing until there are liquid droplets dripping in the condensation tube, the distillation process lasts for 50min, and collect the distillate.

[0043] 2) Composite solvent extraction: add dichloromethane, diethyl ether and pentane mixed liquid volume ratio 1:1:1 to the distillate, extract continuously four times (20mL, 20mL, 20mL, 20mL), and the organic phase is mixed at 5000r / Centrifuge for 10 minutes under the condition of min, take the upper organic phase, add anhydrous sodium sulfate to the organic phase to remove water, and filter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com