Blue Dream white liquor aroma component concentrating method

A technology of aroma components and white wine, which is applied in the field of food science, can solve the problems of difficult analysis of trace components, easy loss of aroma substances, high experimental components, etc., and achieve the effects of reduced loss, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

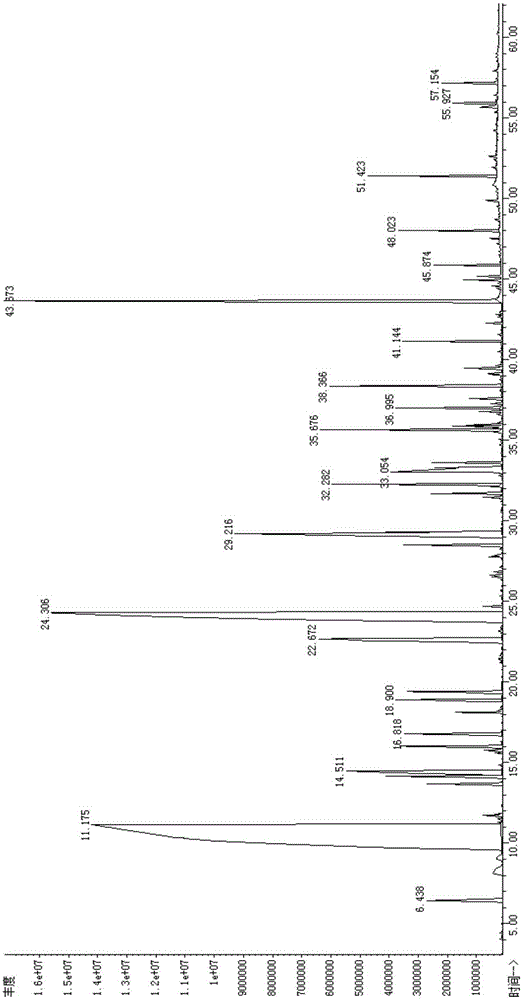

Image

Examples

Embodiment 1

[0015] 1) Composite solvent extraction: Take 25mL of Mengzhilan Baijiu and mix it with 100mL of saturated saline, and put it in a container to obtain the liquid to be extracted; add a mixture of dichloromethane, ether and hexane to the extraction liquid (volume ratio 3:2:1 ), respectively dichloromethane, diethyl ether and hexane mixed solution, respectively take the mixed solution 30mL, 30mL, 30mL for continuous extraction three times, centrifuge the organic phase at 3500r / min for 20 minutes, take the upper organic phase, and add the organic phase without Sodium sulfate water removes moisture, and the organic phase that removes moisture is filtered with a filter membrane of 0.22 μm;

[0016] 2) Thorn-type fractional distillation and concentration: a step of thorn-type fractional distillation and concentration. In the step of thorn-type fractional distillation and concentration, the mixed solution obtained after step (1) membrane filtration is filled into a distillation bottle,...

Embodiment 2

[0028] 1) Composite solvent extraction: Take 25mL of Mengzhilan Baijiu and mix it with 100mL of saturated saline, and put it in a container to obtain the liquid to be extracted; add a mixture of dichloromethane, ether and hexane to the extraction liquid, and take 30mL and 30mL of the mixed liquid respectively , 30mL, 30mL, and 30mL for five consecutive extractions, centrifuge the organic phase at 4000r / min for 15 minutes, take the upper organic phase, add anhydrous sodium sulfate to the organic phase to remove water, and use a 0.22μm membrane filtration;

[0029] 2) Thorn-type fractional distillation and concentration: a step of thorn-type fractional distillation and concentration. In the step of thorn-type fractional distillation and concentration, the mixed solution obtained after step (1) membrane filtration is packed into a distillation bottle and placed in a 50°C The thorn-type fractionation and concentration are carried out in a constant temperature water bath, and the s...

Embodiment 3

[0040] 1) Composite solvent extraction: Take 25mL of Mengzhilan Baijiu and mix it with 100mL of saturated saline, and put it in a container to obtain the liquid to be extracted; add a mixture of dichloromethane, ether and hexane to the extraction liquid, and take 30mL and 30mL of the mixed liquid respectively , 30mL, and 30mL for four consecutive extractions, centrifuge the organic phase at 4500r / min for 10 minutes, take the upper organic phase, add anhydrous sodium sulfate to the organic phase to remove water, and filter the organic phase with 0.22μm membrane filtration;

[0041]2) Thorn-type fractional distillation and concentration: a step of thorn-type fractional distillation and concentration. In the step of thorn-type fractional distillation and concentration, the mixed solution obtained after step (1) membrane filtration is filled into a distillation bottle and placed in a 55°C The thorn-type fractionation and concentration are carried out in a constant temperature wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com