An electrolysis device using magnetoelectric coupling to control the movement of oxygen bubbles

An electrolysis device and magnetoelectric coupling technology, applied in the electrolysis process, electrolysis components, etc., can solve problems such as adhesion of oxygen bubbles on the electrode surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

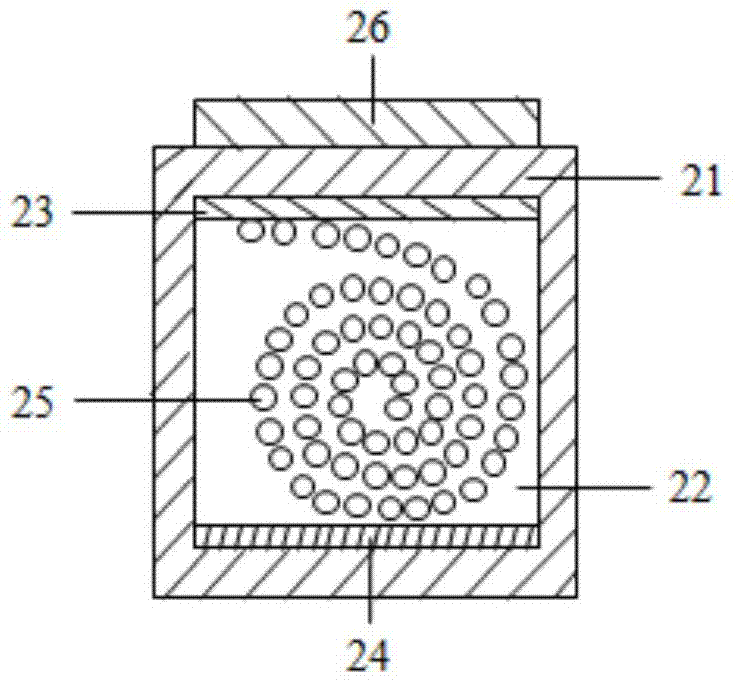

[0025] The device of this embodiment comprises a square electrolytic cell 21 of 70mm * 70mm * 70mm, and a pair of electrodes are installed at two opposite sides of the electrolytic cell, wherein the anode 23 adopts a nickel mesh of 50mm * 50mm, and the negative electrode 24 adopts a stainless steel plate of 50mm * 50mm. The electrolytic solution 22 in the tank is composed of 7mol / L KOH solution and dissolved saturated ZnO, and also includes a 50mm×50mm square NdFeB magnet 26 arranged on the outer surface of the electrolytic tank, and the magnet 26 is closely attached to the corresponding anode 23. location, such as image 3 shown.

[0026] In this embodiment, during the electrolysis process, the oxygen bubbles 25 move to form eddy currents. When the magnet 26S pole faces the anode 23, the oxygen bubble 25 rotates clockwise, as image 3 Shown; If the magnet 26N pole faces the anode 23, the oxygen bubble 25 then rotates counterclockwise. The rotational movement of the oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com