Multi-girder section steel-doublelayer concrete bridge deck composite beam implementing technology

A double-layer concrete and bridge deck technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of multiple processes, long cycle time, and high noise, and achieve the effects of broad application prospects, light weight, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The concrete steps that the present invention implements are as follows:

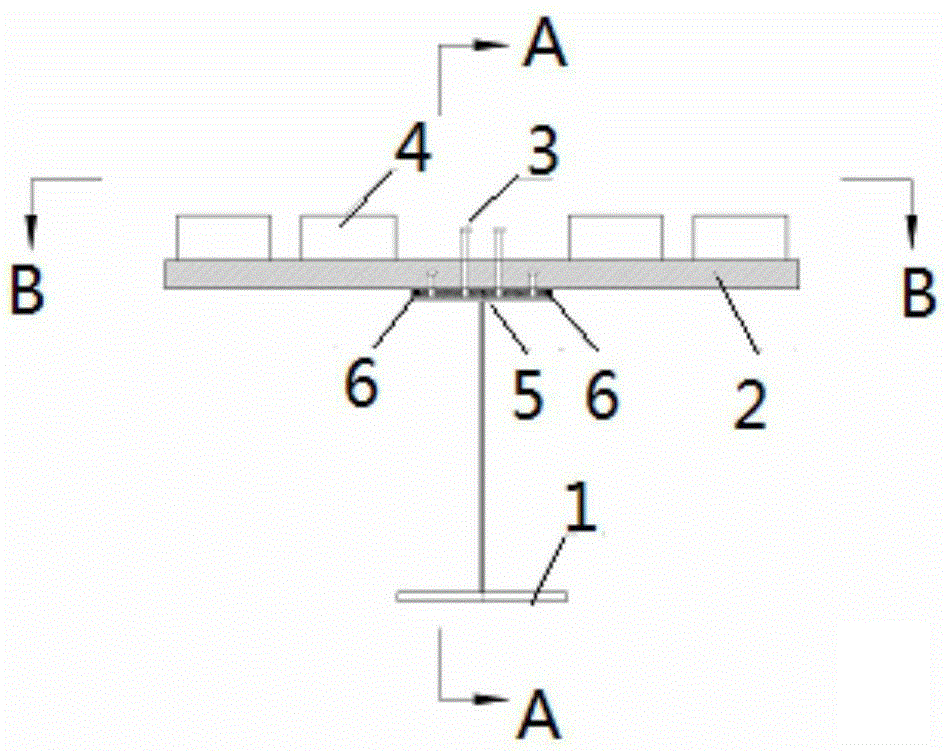

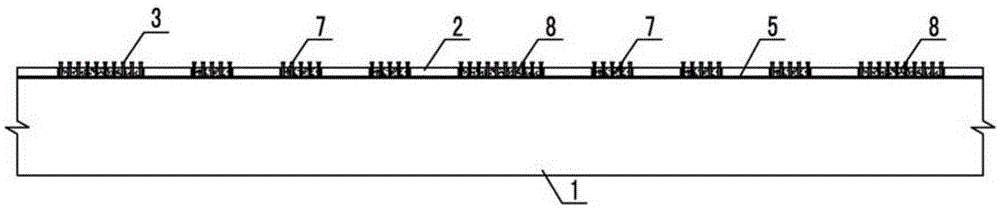

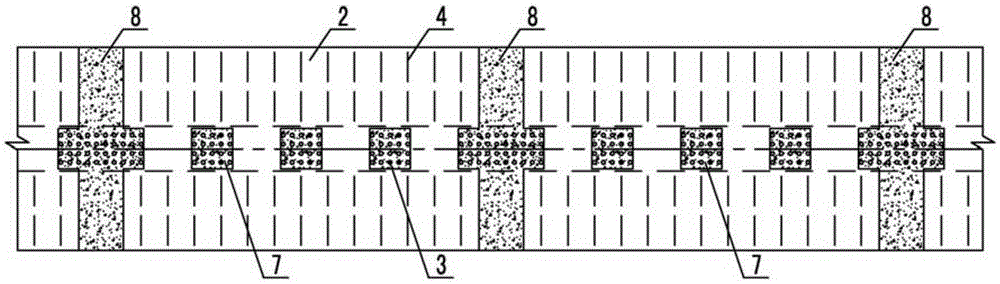

[0026] 1) Weld shear studs 3 on the top of the upper flange plate of "I" shaped steel 1 to form a shear stud group (see figure 1 ); In the factory modular production base plate reinforcement mesh 9 (see Figure 4 ), utilizing the bottom reinforcement mesh 9 to prefabricate the bottom prefabricated concrete bridge deck 2 in the factory, wherein the anchorage reinforcement 4 is exposed;

[0027] 2) Paste elastic rubber strips 6 on the edge of the upper flange plate of the "I" shaped steel, and pour epoxy mortar leveling layer 5 between the elastic rubber strips (see figure 1 );

[0028] 3) Lift and install the bottom prefabricated concrete bridge deck 2, pour micro-expansion concrete 7 and longitudinal wet joint concrete 8 in the shear nail grooves between the bottom concrete bridge de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com